(Updated October 2024) There’s no doubt that a pocket-hole jig makes it super simple to build with wood. It allows you to assemble projects with screws, instead of making complicated joints that require advanced skills and expensive tools. But if you think about it, the pocket-hole jig is really only part of the equation. The pocket-hole screw is actually what holds your pieces together to create a strong, long-lasting joint.

So which screw should you be using? If you’re looking for a fast and simple way to find out what kind your project needs, try our online Screw Selector tool. But if you want to learn the ins and outs of screw selection, we’ll break it all down for you here. After you read this article, you’ll know exactly how to select the right pocket-hole screw for any project.

Which pocket-hole screw should you use?

To choose the right pocket-hole screw, first determine the actual thickness of your wood, then select the appropriate thread type based on whether you’re using softwood, hardwood, or plywood, and finally consider whether your project will be exposed to moisture.

Step 1. How thick is the wood you’re using?

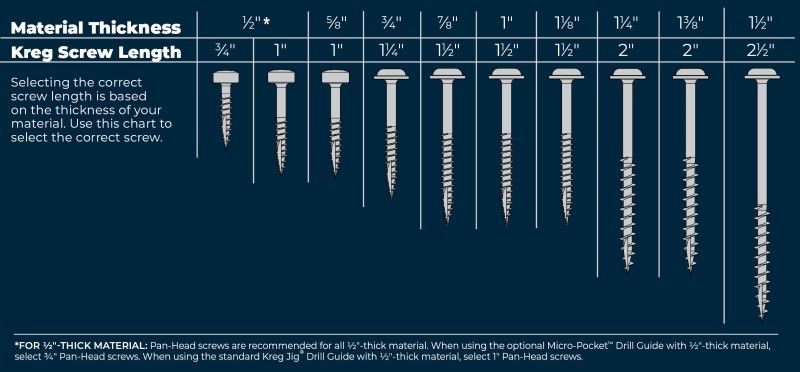

This is the most important thing you’ll want to know in order to select the correct screw. This how-to video shows why it matters so much.

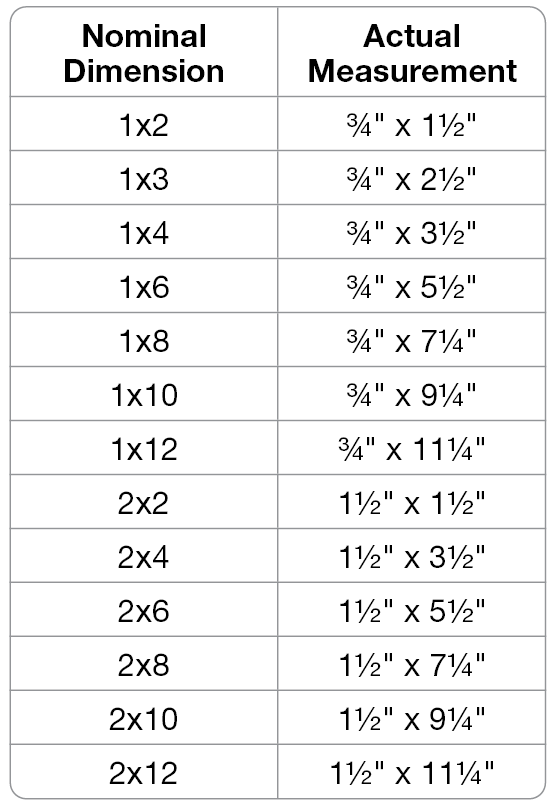

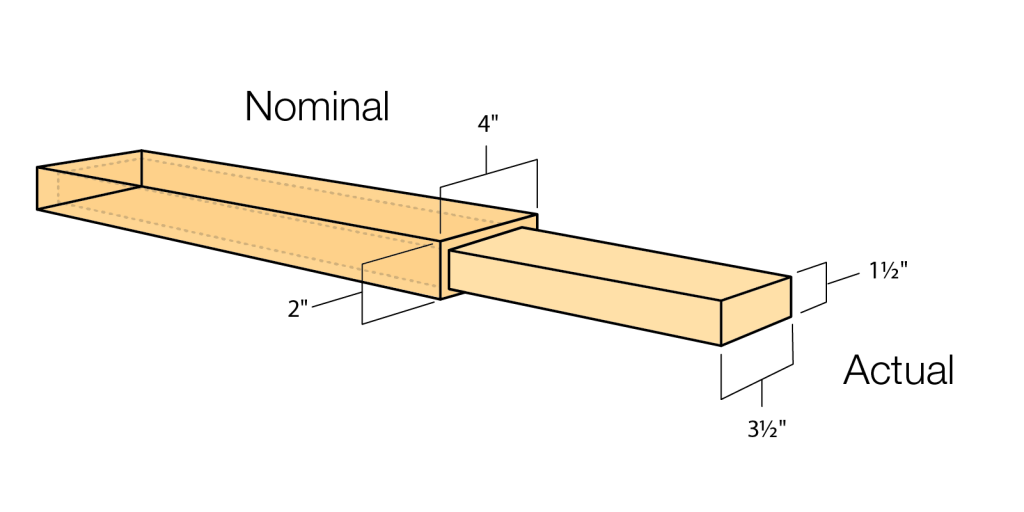

When you’re figuring out your material thickness, be sure to go with the actual measurement. If that seems like a confusing thing to have to say, you’re right. But it’s necessary because most wood sold in home centers is cut to standardized “dimensional” sizes, such as 2×4, 1×6, etc.

The problem is that these names aren’t the actual board dimensions. These are the “nominal” dimensions, which are larger than the actual dimensions. Always be sure, when selecting a Kreg Pocket-Hole Screw, that you use the actual thickness.

Once you know the actual thickness, just refer to your Jig Owner’s Manual or to this handy chart. You can also check out the online Screw Selector tool.

Step 2. What kind of wood are you using?

The next question to ask yourself is: What kind of wood you are using to build your project? Softwood, hardwood, or plywood? When you know that, you can choose the correct screw thread type — either coarse or fine thread.

Coarse-thread screws for softwoods

Woods like pine and spruce, for example (known as softwoods), are soft and not very dense. That means they need a screw with deep, aggressive threads that will bite into those soft fibers. Coarse-thread Kreg Pocket-Hole Screws work great for these woods. Coarse-thread screws are also the preferred choice for sheet goods like plywood and MDF.

Fine-thread screws for hardwoods

On the other hand, hardwoods like oak, maple, and cherry are too dense and hard for coarse-thread screws. The aggressive threads tend to tear the wood fibers, resulting in splits in your wood. For these hardwoods, choose fine-thread Kreg Screws. The threads are less aggressive, but there are more of them to ensure great holding power without splitting.

Step 3. Will your project live indoors or outdoors?

Next, think about where your project will be used. If you’re building an indoor project, your project won’t be subjected to moisture. If you’re building a project for outdoor living, though, you’ll want a screw that can withstand the rigors of exposure to the elements. There’s a Kreg Pocket-Hole Screw for either case.

Zinc-Coated Kreg Pocket-Hole Screws are the ones you’ll use for most projects. They’re recommended for a wide variety of indoor projects that won’t be subjected to significant amounts of moisture. Zinc-coated screws are suitable for use in kitchens and bathrooms.

Blue-Kote™ Kreg Pocket-Hole Screws are the best choice for damp or wet applications, including projects for your porch, patio, detached garage, or outdoor areas. These screws feature 3 anti-corrosion layers to help them resist corrosion in wet areas for the long haul.

Stainless Steel Kreg Pocket-Hole Screws are the ultimate choice for outdoor applications that involve excessive exposure to moisture and corrosive elements.

Stainless Steel Kreg Pocket-Hole Screws are the ultimate choice for outdoor applications that involve excessive exposure to moisture and corrosive elements.

Step 4. Do I really need Kreg Pocket-Hole Screws?

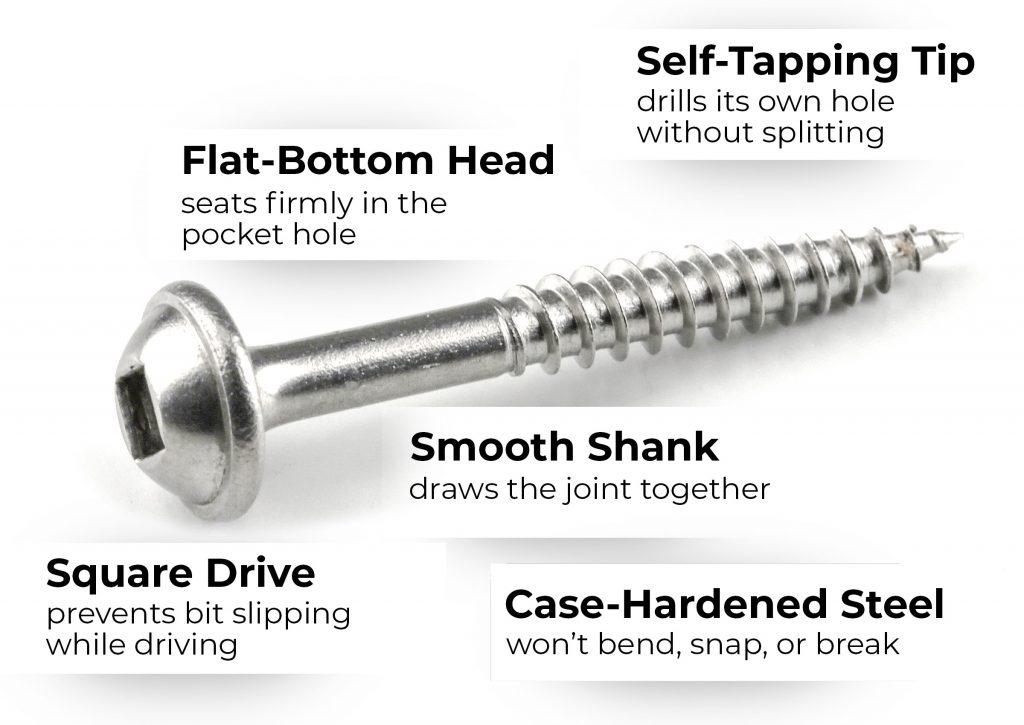

Yes. With all the kinds of screws you can buy in home centers, you might ask yourself if you really need to use Kreg Pocket-Hole Screws to build your projects. Why choose them over wood screws, drywall screws, or deck screws?

The answer is that Kreg Pocket-Hole Screws are engineered for pocket-hole joinery, with specific features that ensure the best performance.

Step 5. Stock up on screws

Step 5. Stock up on screws

Once you know which screw you’ll need, make sure to stock up and keep plenty on hand for your next project! And if you’re ever not sure exactly what screws to use, you can check with the helpful Screw Selector tool.