When you’re building projects from plans, you may wonder why you see things like a “1×4″ board in the materials list, but then see project parts sized at 3/4″ x 3 1/2”. The difference lies in the way lumber size is referred to. Here’s how to understand the differences between the stated “nominal” board size and the “actual” size.

What are nominal lumber sizes?

Nominal lumber sizes are the traditional, convenient names used to identify and specify the different dimensions of lumber. These sizes are based on the rough-sawn measurements of the lumber before it was dried and planed. For example, a piece of lumber labeled as a “2×4” has a nominal size of 2 inches by 4 inches.

What are actual lumber sizes?

Actual size lumber refers to wood that has been planed and trimmed to its final dimensions. It is also known as dressed lumber.

Can you buy actual size lumber?

Yes but it’s essential to pay attention to both the nominal and actual dimensions to ensure it meets your project requirements.

Why the difference between nominal and actual?

The difference between nominal and actual lumber sizes dates back to the early days of lumber production. When logs were sawn into rough boards, they were cut to slightly oversized dimensions to account for the wood’s expected shrinkage during the drying process. Additionally, the boards were further planed smooth, removing some of the material and resulting in the final, slightly smaller actual dimensions.

This practice of using nominal sizes became an industry standard, allowing for consistent communication and ordering of lumber sizes despite the slight variations in actual dimensions that occurred during manufacturing.

What size is rough cut lumber?

Rough cut lumber refers to wood that has been sawn from the log but not planed or trimmed to its final dimensions. It is typically sold in nominal sizes, which are slightly larger than the finished dimensions.

For example, a 2×4 piece of rough cut lumber may actually measure closer to 2 inches by 4 inches.

What are the standard lumber sizes?

Common standard sizes for dimensional lumber in the United States include 2×4, 2×6, 2×8, 2×10, and 2×12, with lengths typically ranging from 8 feet to 16 feet.

What are the most popular lumber sizes?

Among the standard sizes mentioned above, 2×4 and 2×6 are among the most popular for various woodworking projects due to their versatility and availability.

![]()

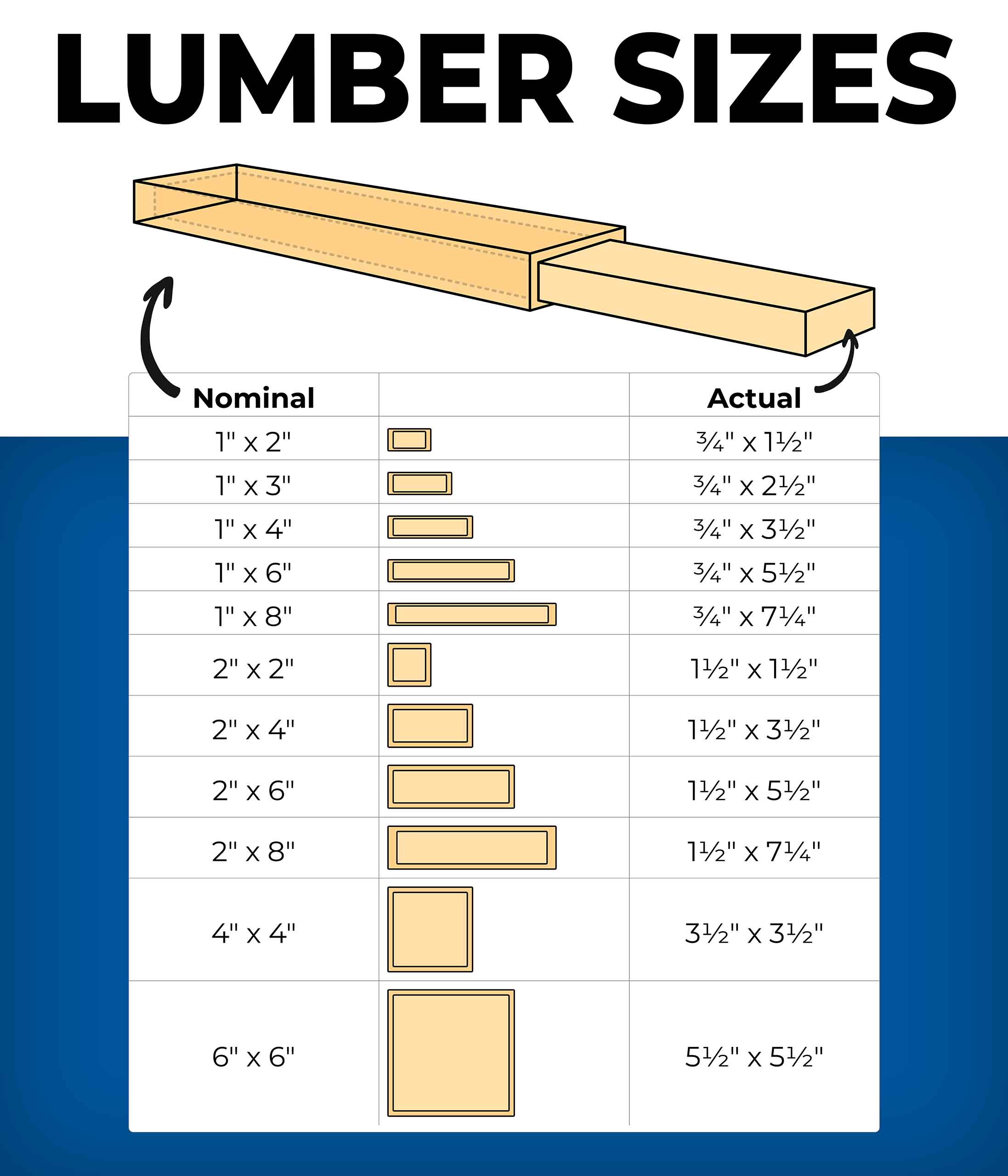

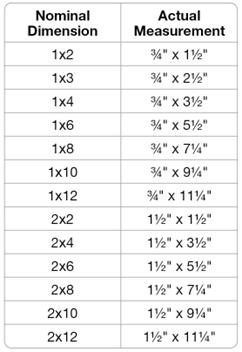

Dimensional Lumber Sizing Chart

To help you understand the relationship between nominal and actual sizes, here’s a handy chart outlining the most common dimensional lumber sizes:

Specialty Lumber Sizing

In addition to dimensional lumber, there are various specialty lumber products with their own sizing conventions:

Decking and patio plank dimensions

5/4” x 6″

1″ x 5-1/2″ (Actual dimensions for decking boards)

Glue-laminated beam dimensions

Glulam beam dimensions follow the same nominal vs. actual size relationship as dimensional lumber. Common glulam beam sizes include 3-1/8″ x 5-1/8″ up to 3-1/8″ x 24″.

Engineered wood product dimensions

Engineered wood products like laminated veneer lumber (LVL) and parallel strand lumber (PSL) are manufactured to precise dimensions, so their listed sizes are generally their actual sizes.

![]()

Standard Lumber Lengths Explained

While lumber dimensions can vary, the standard lengths of lumber are more consistent. Most dimensional lumber is available in lengths from 6 feet up to 20 feet, in 2-foot increments (6′, 8′, 10′, 12′, etc.). Longer lengths up to 24 feet may also be available, depending on the supplier and lumber species.

One important note is that longer lengths can sometimes have slight variations of an inch or two from the stated length due to manufacturing tolerances.

How to Calculate Board Feet

When purchasing lumber, it’s often sold by the board foot, which is a measurement of volume equal to a 1-inch thick, 12-inch wide, 12-inch long piece of lumber. To calculate board feet, use this formula:

(Thickness in inches x Width in inches x Length in feet) / 12 = Board Feet

For example, a 2x6x8 foot board would be:

(1.5″ x 5.5″ x 8′) / 12 = 5.5 board feet

Understanding board feet helps you purchase the right amount of lumber for your project and avoid extra trips to the store or having excess leftover material.

![]()

How Lumber is Manufactured

To better appreciate the difference between nominal and actual sizes, it’s helpful to understand the lumber manufacturing process:

- Logs are initially sawn into rough boards at the mill, with excess dimensions to account for anticipated shrinkage.

- The rough boards are then kiln-dried to remove moisture, causing them to shrink slightly.

- After drying, the boards are planed smooth on all four sides, further reducing their thickness and width to the final actual dimensions. It’s this shrinkage from drying — followed by planning — that creates the difference between the original rough-sawn nominal size and the smaller final actual size of a finished lumber board.

![]()

Tips for Buying the Right Lumber Size

Factoring shrinkage

Depending on the moisture content of the lumber when purchased, some additional shrinkage may occur as the wood continues drying and acclimating to its environment. Generally, shrinkage is modest for kiln-dried dimensional lumber, but can be more significant for green (undried) lumber. Factor in an additional 5-10% potential shrinkage when working with green lumber to ensure your final part dimensions are accurate.

Green vs dry lumber

Green lumber is cheaper than kiln-dried, but requires additional drying time and is prone to greater shrinkage, twisting, and checking (cracks). Kiln-dried lumber is more stable and can generally be used as-is for most projects.

Rough vs planed lumber

Rough-sawn lumber retains its original surfaces from the sawmill, while planed lumber has had its surfaces milled smooth. Planed lumber has already had its dimensions reduced from the planing process.

Understanding actual vs nominal lumber dimensions, how lumber is manufactured, and the purchasing considerations, you’ll be able to select and work with lumber more accurately on your next project. Remember to always measure and verify the actual dimensions, and plan accordingly for the expected real-world sizes. With this knowledge, you’ll avoid miscalculations and ensure your next project turns out just right.