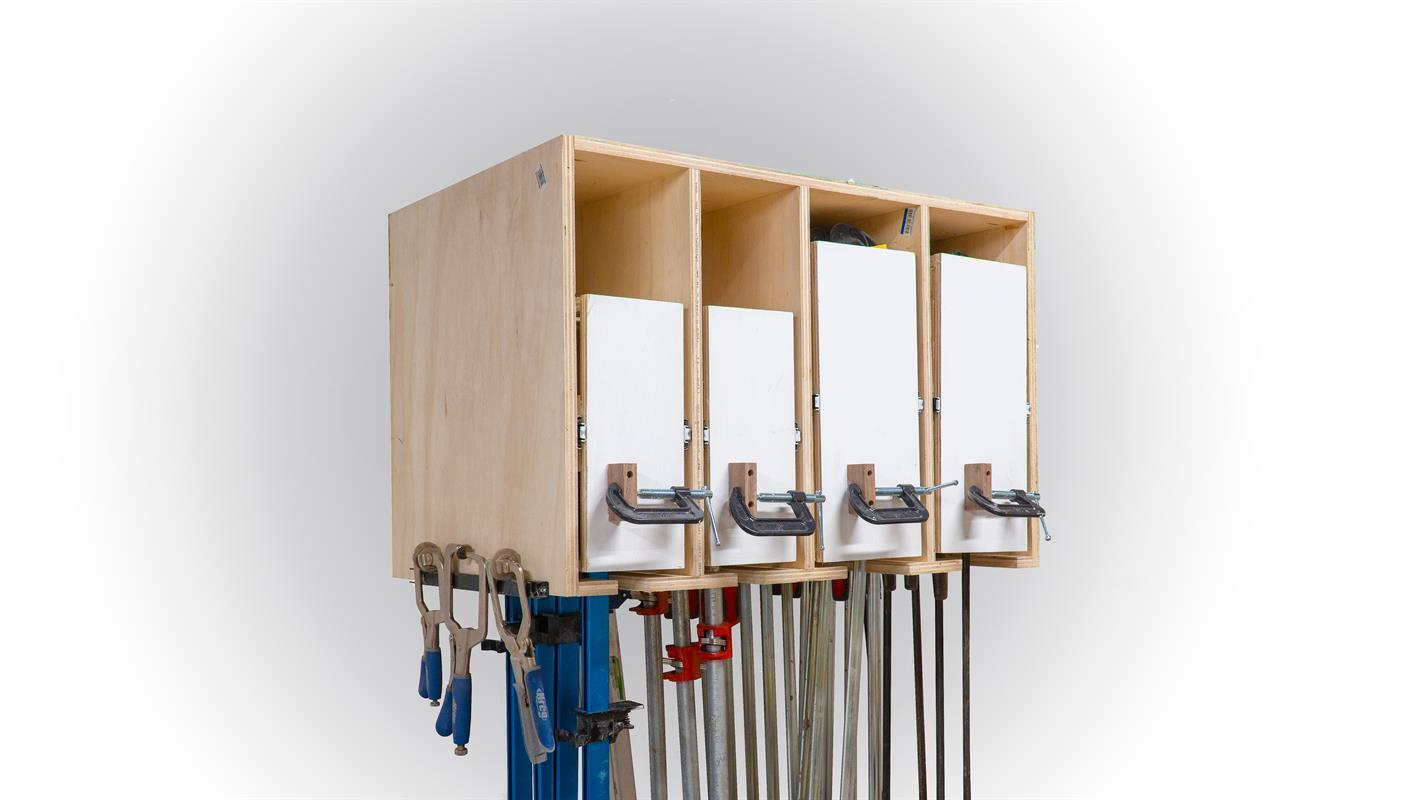

Space Saving Clamp Rack for a Small Shop

By WoodWorkLIFEI had a simple problem, a blessing really, I have too many clamps and a small shop. I am also sick of getting hit with clamps falling of my wall and dusty dirty clamps. I solved this problem by cramming 56+ clamps into 4 sq/ft of wall space using semi enclosed drawers checkout the full video below.

Directions

-

Cut-it-Out

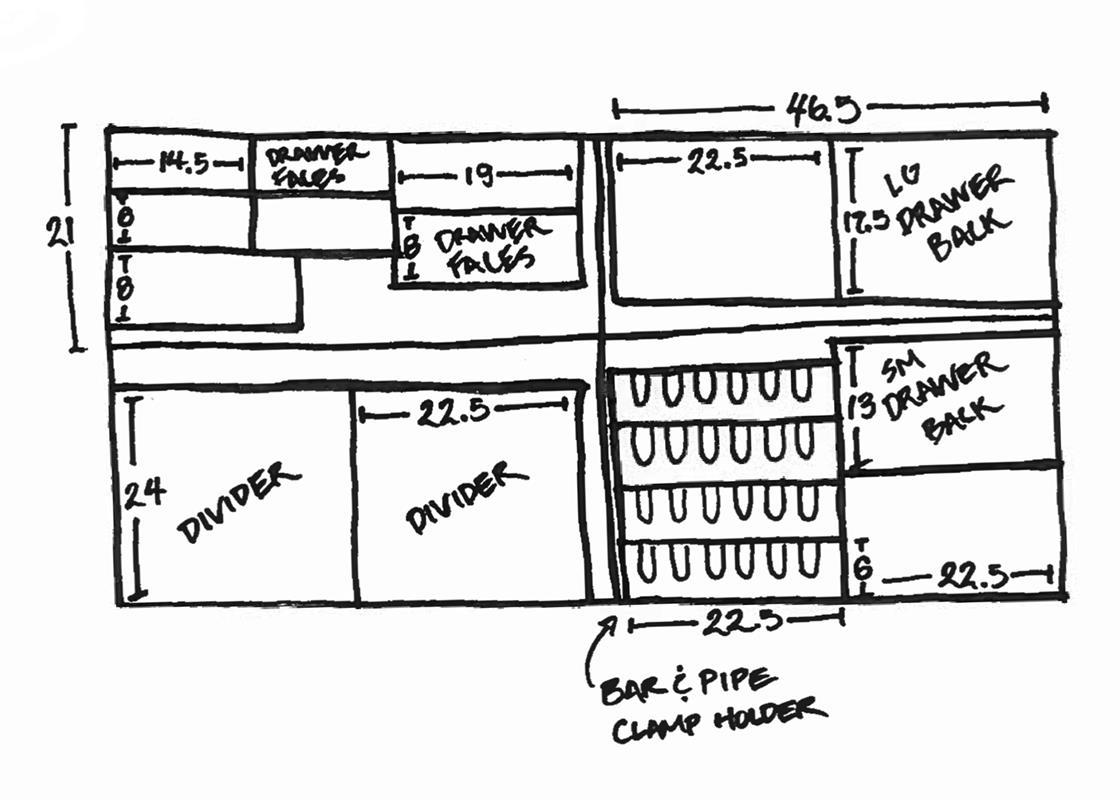

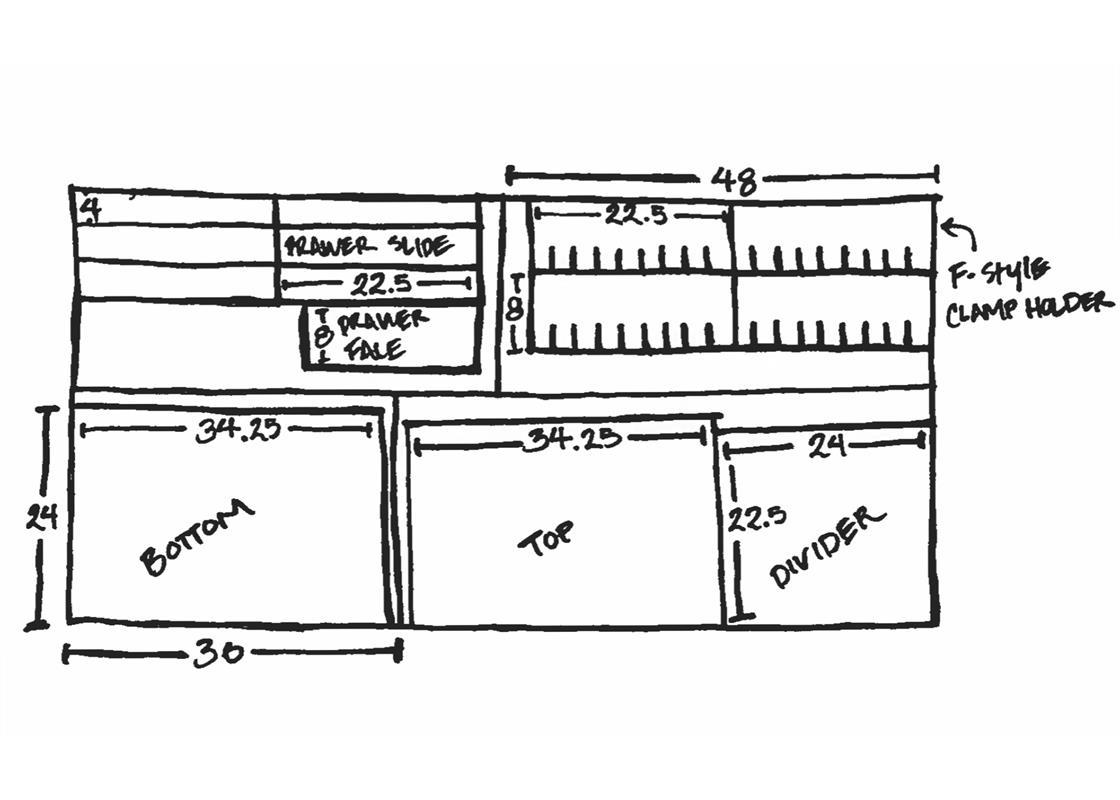

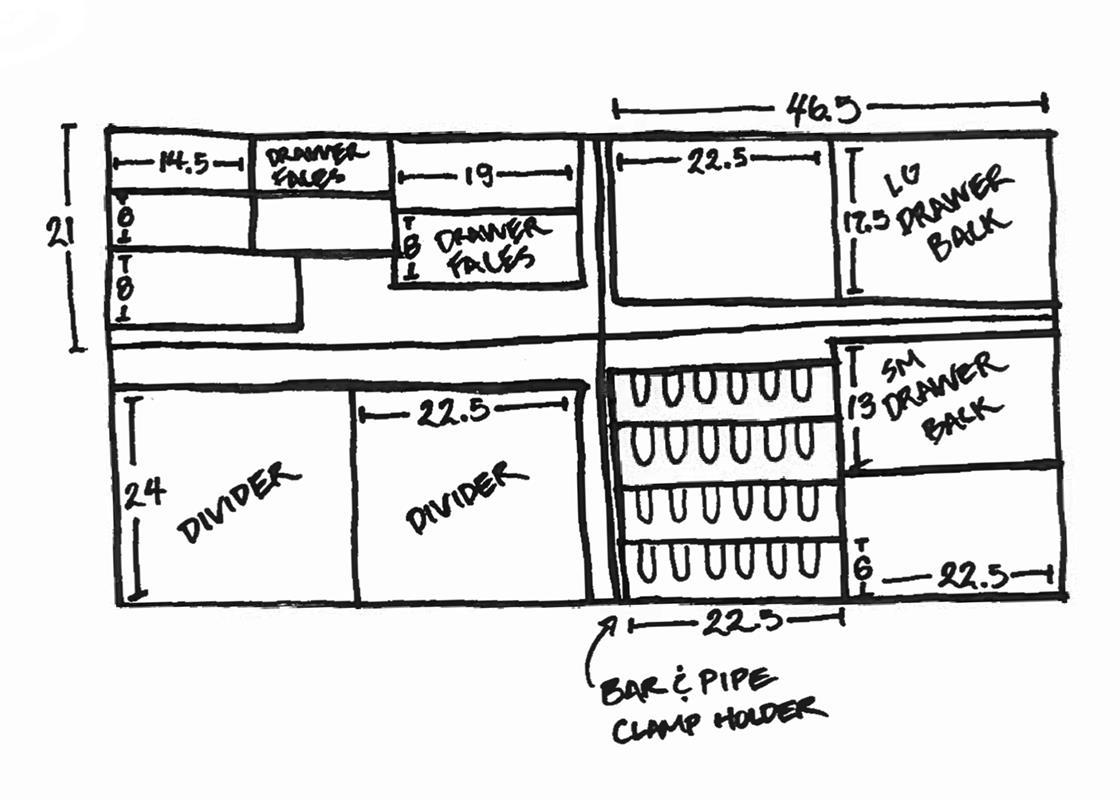

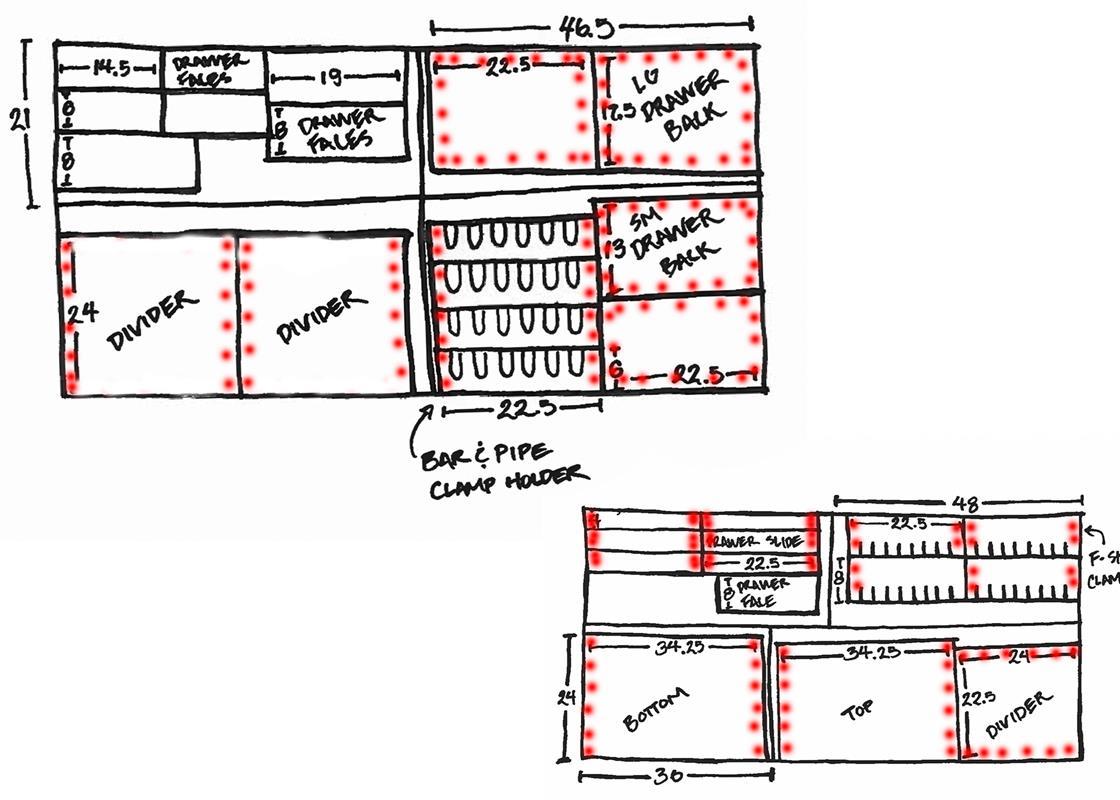

This project starts with 2 and a 1/4 YES, TWO AND A QUARTER sheets of 3/4 inch plywood. I did however go through the effort to optimize the cutting of these sheets to get as much yield out of the sheet with as many useful scraps as possible. I also have cut lines and dimensions labeled on the cut list to let Home Depot break the sheets down for you so you have easier to manage sheets to work with at home. The only pieces not marked on the cut list are the two side pieces and that is because these should be 24" x the length of your dividers + the thickness of two pieces of your plywood, because not all 3/4" plywood is the same.

[Quick note: Mark your pieces as you go through the steps of breaking down your pieces, you'll thank me later

-

Pocket Hole Time

Put on your favorite T Swizzle track, or whatever it is that you like to listen to while you shake it off.

I have all of the positions marked on the pieces to pre-drill all of the pocket holes. Normally I would've done this with my K5 but for this project I was actually able to try out the Kreg Foreman. Either way, this is quick work. I recommend going through all of your pieces and scribble lines where your pocket holes need to be cut THEN going through and cutting them all so you can zone out and get it done.

-

Assemble the Vertical Drawers

I designed these drawers for ease of assembly. The only thing I would recommend it to check for square at all mating corners as you go.

I assembled these by laying the back panels for each drawer on a flat surface then clamping, gluing, and pocket screwing the two clamp rack surfaces to the top and bottom. After this I attached the front and back panels with glue and pocket screws.

Finally, I attached the "stretcher" to the front of the case. I did this by marking the vertical center of the opening, and the middle of the stretcher. I then clamped the opening of the cabinet (drawer?) slightly to tighten up any bowing in the cabinet. Then I matched up the center points and attached it with glue and pocket screws.

-

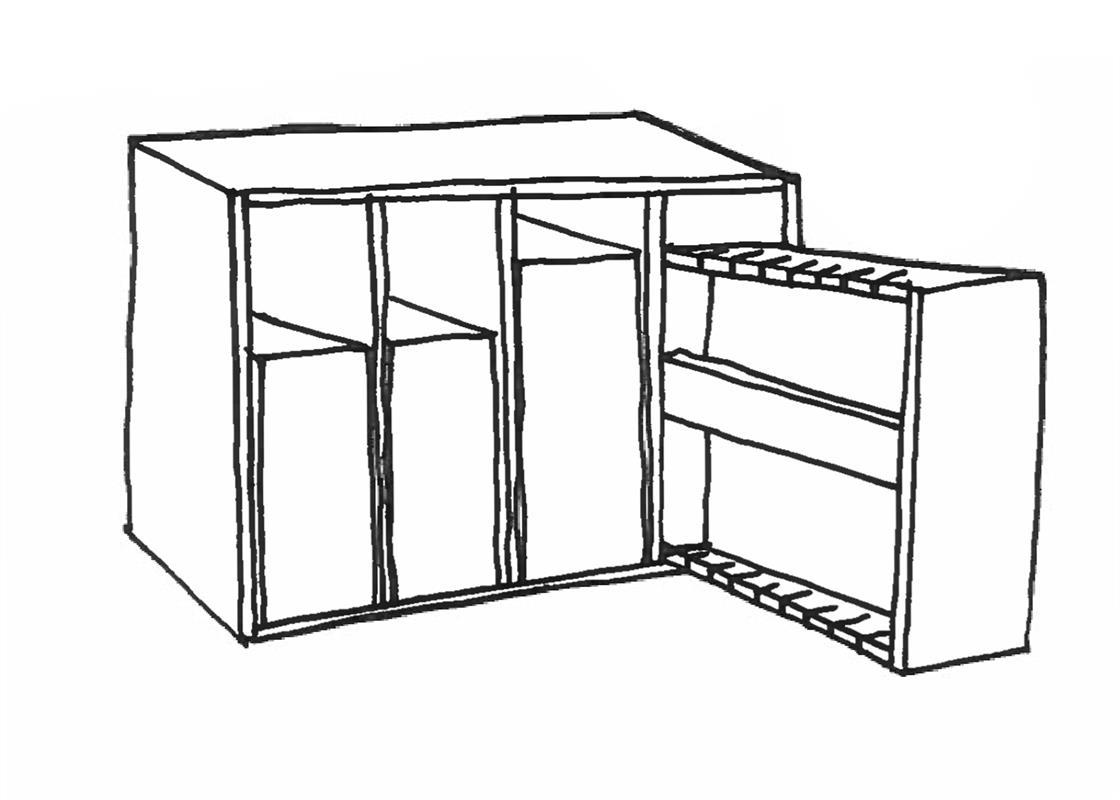

Carcass & Dividers

With the drawers complete, it is time to move on to the carcass. It is key to keep all of the panels square and plum and properly spaced for the subsequent steps. I first started with the side panels by drilling the top and bottom of the carcass into the sides. I used corner clamps to keep all 4 corners square as I assembled the carcass using glue and 1 1/4" pocket hole screws.

With the outer assembly of the carcass complete it was time to insert the 3 center dividers. Using 1/2" drawer slides the dividers are installed with 2 7 inch compartments and 2 9" inch compartments ensuring the dividers are square and plum.

-

Cutting clamp holders

This can be done several different ways. I would suggest laying out your clamps and figuring out the optimal way to place the clamps you have.

I chose to cut the clamp holders by first marking 8 sections in the 8" wide tops and bottoms and 6 sections in the 6" sections. On the top 2 pieces of the 8" sections I drilled 1/2" holes then cut 1/2" slots at the table saw using a miter sled (check out the video for more details: https://youtu.be/XYkBEra-Fr4?si=7XbHbt6CdBizz_9x)

For the bottom section, I drilled 1 5/8" holes (for the handles of my Bessey clamps) then cut 1/2" slots at the table saw. For the bar clamps (the 6" drawers) I drilled 1 5/8" holes and then connected them with 1 5/8" slots on the top and bottom.

-

Drawers slides & Drawers

I attached the the drawers slides centered on the drawer slide mounts and equally spaced on the back of each vertical drawer. I then placed the corresponding piece on the inside of the compartment adding an extra 1/2 an inch (relative to the center of the drawer slides attached on the vertical drawers) to ensure free motion of the drawers.

I used 100 lb drawer slides, and they work fine in this orientation but you might want to use 200 lb slides if you wanted to make this thing bullet proof. The cost of 200 lb slides may be prohibitive though.

-

Wall Mounting

To wall mount this cabinet I recommend a hearty french cleat and long structural screws attached to studs.

I used an 8" Cleat attached directly to the top of the back of the carcass and dividers using glue and several 1 3/4" pre-drilled screws.

I then attached a full width by 16" hook to the wall directly into the studs using 8 3" structural screws.

After hooking the french cleat into the hook on the wall, I drove 4 more 3" structural screws through the cleat into the studs to lock in the cabinet. This should handle the cantilevered weight of the cabinet fully loaded, particularly if you use high quality 13 ply birch ply. Cheaper plywood might break down over time and become weaker.

-

Prettying it up

I designed this cabinet with the idea that I could install french cleats or pegboard on either side of the cabinet for even more storage. I am not exactly sure how I am going to utilize this extra space so I didn't install anything yet.

I also used a couple of 3" C clamps locked onto small blocks of walnut I glued and screwed to the front of the cabinets. I wanted the drawer hardware to serve as yet more clamp storage.

I also spruced up the faces of the cabinets with a touch of paint. with all of this surface area you could also use chalk paint or attached white board to these faces for a place to jot down some notes.