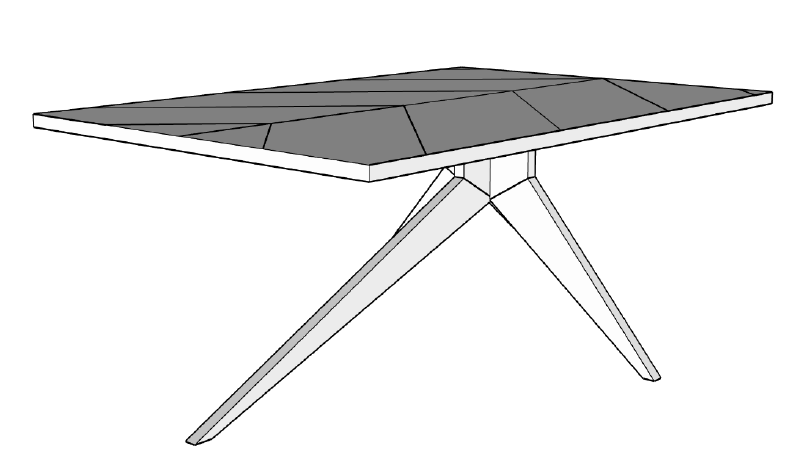

Leaf Coffee Table

By Modern BuildsBuild this leaf-shaped coffee table with a mid-century modern-inspired base.

Directions

-

Watch the video!

We recommend watching the corresponding video before beginning this build. Link in Extras!

-

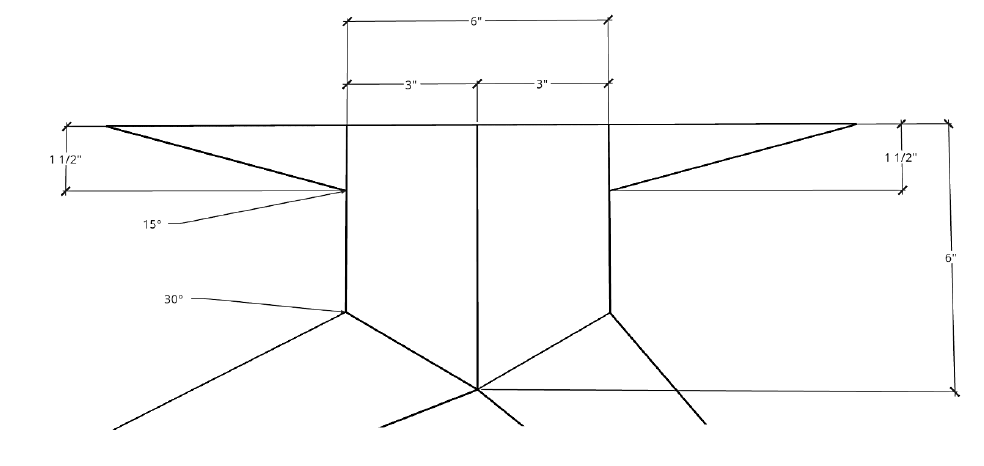

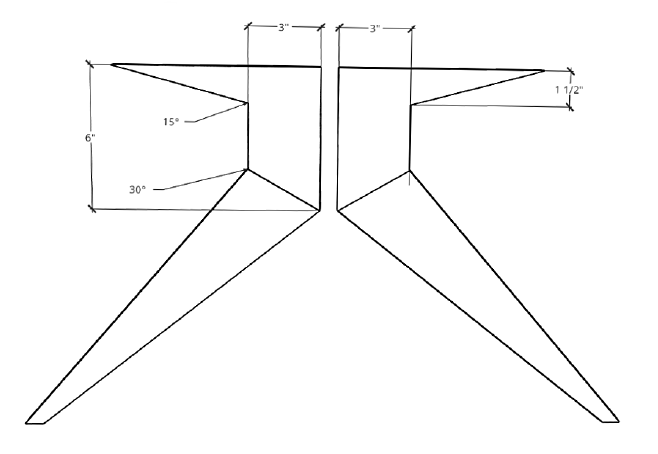

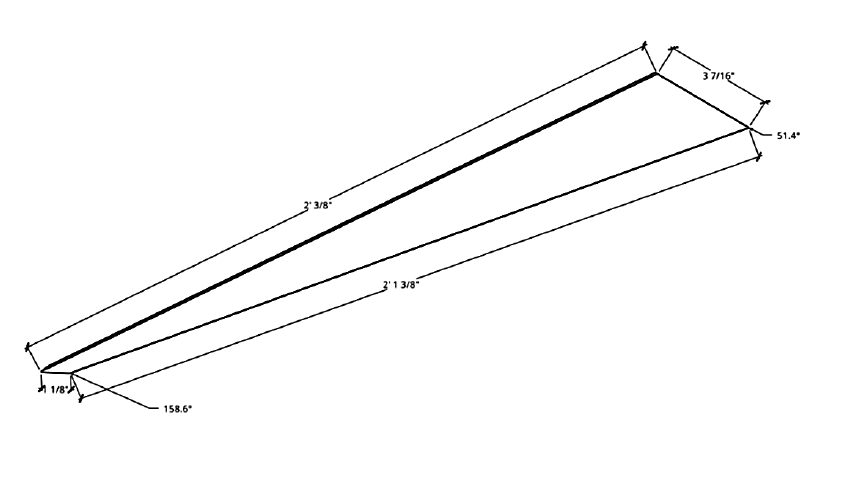

Cut 3 short legs

Cut the 3 short legs with the angles mentioned here in the image.

-

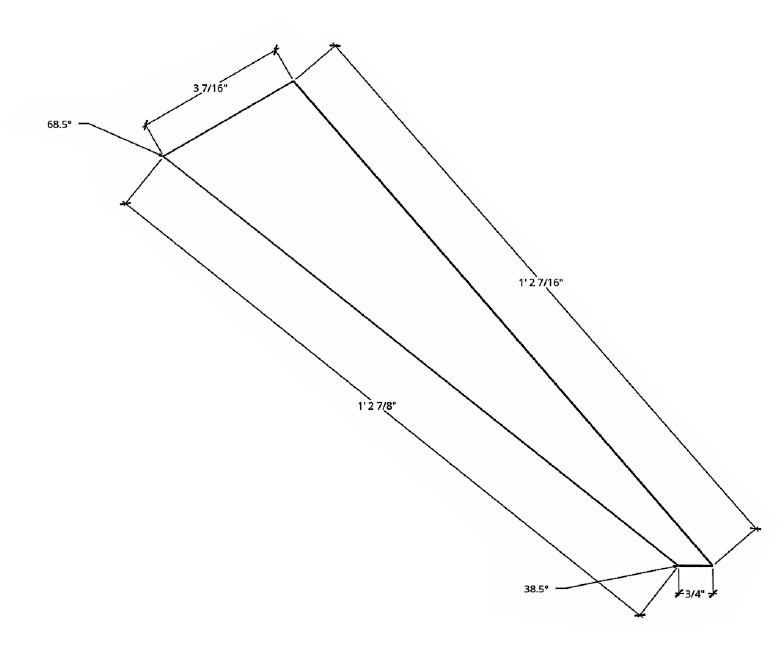

Cut 1 long leg

Cut the 1 long leg with the angles mentioned here in the image. The angles here are important as they will determine if the table is flush.

-

Cut center "hub"

The center "hub" connects to the long center leg and one short back leg. The most important measurement is the 30 degree cut where the legs connect. See image here for angle details. You'll attach the long leg and one short leg to the base of the hub with pocket-holes and wood glue.

-

Cut side "hub" pieces

The "hub" pieces that connect left and right legs are the same as the center hub, but you'll cut it in half. You'll also join the remaining two short legs with pocket-holes, as shown in the diagram here.

-

Plug pocket holes

Using Kreg's pocket-hole plugs, plug each of the pocket holes with wood glue. Once they're dry, use a hand saw and a flat file to get the plug flush with the rest of the project.

-

Attach first side hub to main hub

Attach the first side hub you had cut in half previously to the main center hub using the same 1 1/4" fine pocket-hole screws.

-

Attach second hub with pocket holes

Attach the second hub with pocket holes on the opposite side of the main hub. Don't forget to plug these pocket holes when you're done!

-

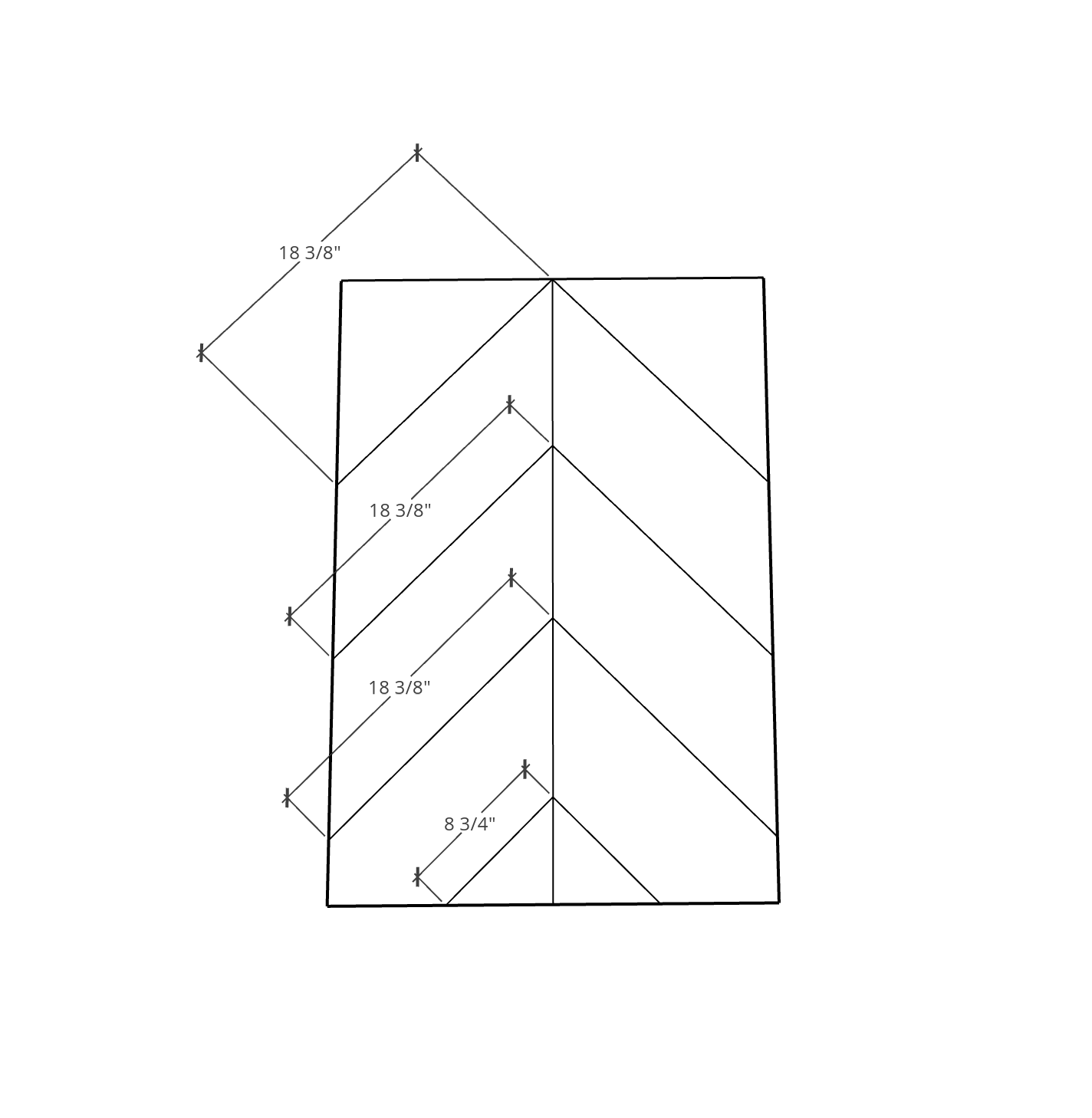

Cut the pieces for your table top

I cut the pieces at 45 degrees on each end to mimic the grain of a leaf. I recommend making the table top a little oversized before trimming the outline.

-

Lay out boards for tracing the leaf pattern, and pocket hole boards together

Arrange the boards you just cut in a chevron pattern to mimic the grain of a leaf. Don't connect them quite yet!

Cut out your leaf pattern and lay it on top of the boards. Trace the outline of the leaf.

Mark responsible locations for your pocket holes, based on where the outline of the leaf lies. You'll want to make sure you avoid cutting through any screws when cutting out the outline. Drill pocket holes on one side of the table top, and connect them with wood glue and screws. Repeat on the other side, and wait for both sides to fully dry before connecting them together to form one full table top. I tried to make sure that I was using two screws to hold each 1x8 together.

-

Trace leaf pattern onto table top, and cut

Trace the leaf pattern onto your table top, and I used a clean jig saw blade to cut the outline for the best possible cut. Then I sanded the edges with 120 grit sandpaper, and worked my way up to 220 grit. You'll have to hand sand all of the cutouts. A half round file is really convenient in this application.

-

Plug pocket holes on table top

Plug all the pocket holes on your table top with wood glue, and cut and sand them flush like you did in the table base.

-

Sand the table top

I started with 80 grit to get everything flat and smooth, and worked my way up to 220 grit.

-

Attach the base to the table top

I added wood glue and a couple of screws to attach the table top to the base. Kreg's 90 Degree Driver really helped with the screws here as the angles of the tables made it difficult to reach the screw locations.

-

Apply finish

Apply finish to your entire table. I used Maker Brand Simple Finish. Danish oil, polyurethane, or wipe-on poly oil would also be a great solution.