One of the most-common things people ask us about pocket-hole joints is what determines the best spacing between the pocket holes. We’ve built a few features into the drill guides on our Pocket-Hole Jigs that make pocket-hole spacing easy. It’s all based on the width of your boards or the size of your workpiece.

We think you’ll find these guidelines helpful. Remember, though, that one of the best things about pocket-hole joinery is that it doesn’t have to be exact. Because there are no pilot holes in the mating pieces, it almost never matters if there’s a little variation in where you drill the holes.

Drill Guides offer easy spacing options

Kreg Pocket-Hole Jigs all have hardened-steel drill guides that are positioned to give you hole-spacing options. This explains why, on models with multiple drill guides, the spacing between the drill-guide holes isn’t always even.

If you have a Pocket-Hole Jig 720, Pocket-Hole Jig 720PRO, or a Pocket-Hole Jig 520PRO2, you’ll see that there are three holes, and they’re not evenly spaced. We made the spacing different on purpose because it allows you multiple choices without having to change your jig setup.

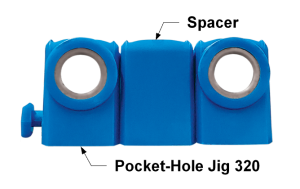

The Pocket-Hole Jig 320 is a little different. It has two individual drill guides, plus a spacer in between. You can remove the spacer to change the distance between the two holes.

Board width or material size determines pocket-hole spacing

The built-in features in our drill guides are used most often when you’re drilling pocket holes in the end of a board. That’s where you’ll place them for projects like frames. In those cases, pocket-hole spacing is determined by the width of the board. If you’re putting pocket holes along the edge of a board, or if you’re building with plywood, pocket-hole spacing changes a bit. Let’s look at both cases.

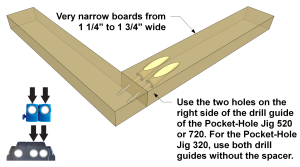

Pocket-hole spacing in 1×2 and 2×2 boards

When you’re working with narrow boards, such as a 1×2 or a 2×2, you’ll want to place the pocket holes close together. This allows you to fit two holes side by side on a narrow board, which provides a joint that’s stronger than using a single pocket-hole.

If you’re using a Pocket-Hole Jig 520, 720, or 720PRO, use the two holes at far right. For the Pocket-Hole Jig 320, remove the spacer, reconnect the drill guides, and then drill both holes.

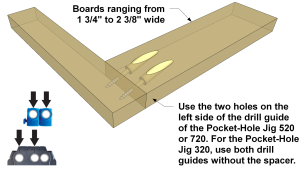

Pocket-hole spacing in 1×3 and 2×3 boards

As the boards you are using get a bit wider, like 1x3s and 2x3s, you may be able to increase the space between pocket holes, depending on which jig you are using. If you’re using a Pocket-Hole Jig 520, 720, or 720PRO, use the two holes at the left this time.

With the Pocket-Hole Jig 320, inserting the spacer would put the pocket-holes little too close to the outside edges of the board. So, go ahead and leave the spacer out for these slightly wider boards, as well.

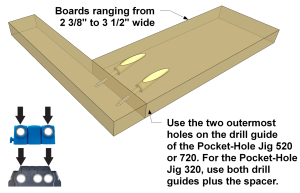

Pocket-hole spacing in 1×4 and 2×4 boards

A lot of people build projects using 1×4 and 2×4 boards, so our drill guides have built-in spacing options for those board widths, as well. If you’re using a Pocket-Hole Jig 520, 720, or 720PRO, use the two outermost holes—the ones at far left and at far right.

With the Pocket-Hole Jig 320, you can insert the spacer to spread the pocket holes farther apart.

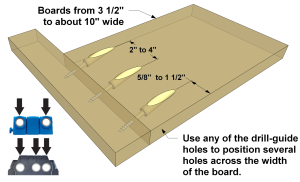

Pocket-hole spacing in wider boards

What if you’re using wider boards? We don’t make drill guides with wider spacing. So, you’ll want to reposition the board in the jig to space the holes farther apart.

With boards up to 10″ wide or so, we find it works well to use three pocket holes—one in the center, and one nearer to each edge. That gives great holding power but won’t interfere with the board’s ability to expand and contract across its width seasonally. All boards do this as humidity levels change throughout the year.

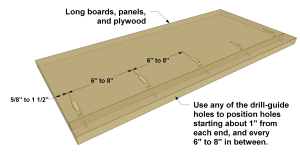

Pocket-hole spacing in plywood, panels, and long boards

Of course, pocket-hole joinery isn’t just used at the ends of boards. You can also use pocket-hole joints along the edges of long boards to create things like table tops. And pocket-hole joints are great for sheet goods like plywood and MDF.

Whether you’re drilling along the edge of long boards or you’re working with sheet goods, our recommendations for spacing are the same. Place a pocket hole close to each end, and then space them out every 6″ to 8″ in between.

Hopefully, these tip make pocket-hole spacing easier to understand, and will help you make strong joints that last, and make them fast on your next project. Now, go start building!