Woodworking can be described by saying it’s as much about understanding the fundamentals and nuances of joinery as it is about anything else. Among the myriad of woodworking joints, the simple butt joint stands out as one of the most versatile options available to woodworkers. Let’s take a look at the intricacies of butt joints by exploring types, uses, advantages, disadvantages, and how to create them.

What is a butt joint?

When compared to other joinery methods, a butt joint is the most elementary form of connection between two pieces of wood. Unlike other joints where pieces interlock or overlap, a butt joint involves joining the ends or edges of two pieces of wood directly against each other.

While it may seem basic, mastering the art of creating strong and reliable butt joints is crucial for woodworkers of all skill levels.

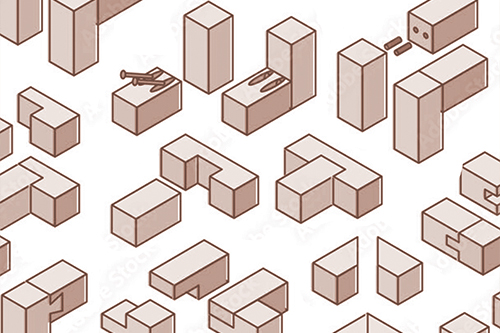

Types of butt joints

Square butt joint

This classic butt joint involves the simple alignment of two pieces of wood at a right angle, forming a corner without any overlapping.

Mitered butt joint

In a mitered butt joint, the ends of each piece are cut at a 45-degree angle, creating a seamless corner with no visible end grain.

Beveled butt joint

A beveled butt joint features one end of each piece cut at an angle, allowing for a flush connection when joined together.

T-butt joint

In this variation, one piece of wood overlaps the other perpendicularly, forming a T-shape when viewed from the end.

Each type of butt joint offers its own advantages and disadvantages, making them suitable for different woodworking applications and aesthetic preferences.

Where are butt joints used?

Butt joints find application in various woodworking projects – they are commonly used in cabinet construction, basic furniture assembly, framing and other tasks that require quick joinery

Cabinet construction, including drawer boxes and cabinet frames.

Basic furniture assembly, such as tables, chairs, and bookshelves.

Picture frames, window frames, and door frames.

General carpentry and woodworking tasks that require quick and reliable joinery.

Advantages of butt joints

Simplicity

Butt joints are easy to construct and require minimal tools and expertise, making them accessible to woodworkers of all skill levels.

Versatility

They can be used in a wide range of woodworking projects and applications, offering flexibility and adaptability.

Reinforcement

Butt joints can be reinforced with various methods, including glue, screws, dowels, or biscuits, to enhance strength and durability.

Disadvantages of butt joints

Lack of relative strength

Compared to other joints like dovetails or mortise and tenon joints, butt joints lack inherent strength and may require additional reinforcement for optimal performance.

Visible end grain

In certain applications, the visible end grain of butt joints may detract from the overall look of the project.

Vulnerable to splitting

Without proper reinforcement, butt joints can be prone to splitting and weakening under stress, especially in hardwoods or high-stress areas.

How to make a butt joint

Creating a basic square butt joint can be done in a few simple steps.

Layout

Measure and mark the location of the joint on both pieces of wood using a pencil and ruler.

Cutting

Make a straight cut across the grain at the marked location, ensuring the ends are square and smooth for a flush fit.

Fitting Align the cut ends of the pieces together to form a corner or straight edge joint, ensuring proper alignment and fit.

Prep

Get the pieces ready to connect by sanding or smoothing the cut edges to remove any roughness or imperfections.

How to connect a butt joint

Various methods can be used to connect and reinforce butt joints, including:

Glue

Apply wood glue to the mating surfaces and clamp the joint until the glue dries, forming a strong and durable bond between the pieces. Glue is also essential for strength when using nails, screws, dowels and biscuits.

Nails

Typically used in drawer boxes and picture frames, using a nail gun to complete a butt joint is fast but results in a comparatively weak result.

Screws

Pre-drill pilot holes and drive screws through one piece and into the other.

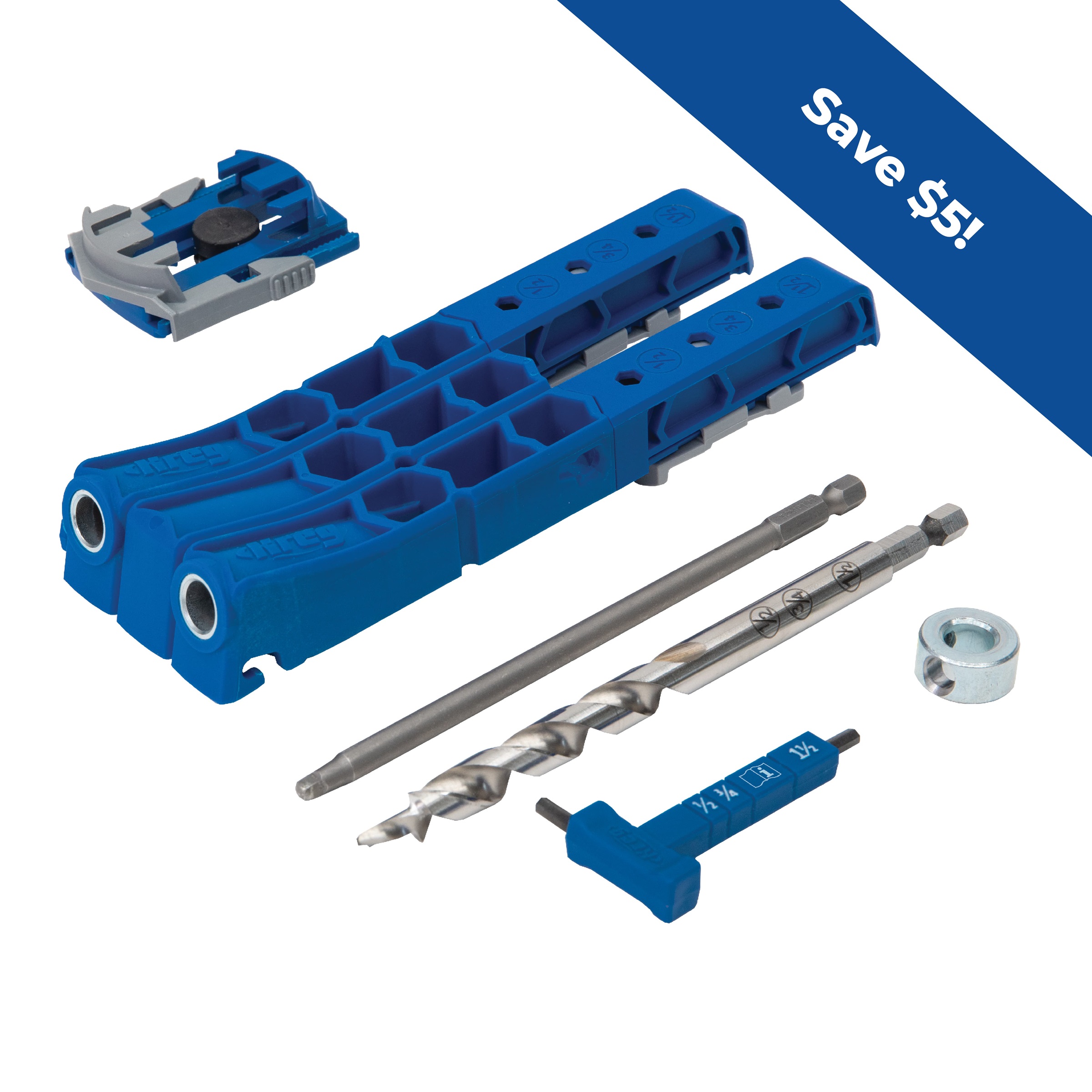

Pocket Holes

An angled pocket is drilled into one piece, with a specialized screw then driven through the hole into the mating piece. This method offers much better joint stability and strength than relying on screws driven straight into the pieces.

Dowels

Drill corresponding holes in both pieces and insert dowels for alignment and added strength, creating a sturdy and reliable connection.

Biscuits

Use a biscuit joiner to cut slots for wooden biscuits, which helps align and reinforce the joint, enhancing stability and durability.

Each method offers its own set of advantages and considerations, allowing you to choose the best option based on the requirements (use, environment, weight considerations, etc.) of the project.

To strengthen a basic butt joint, many woodworkers turn to dowel joinery. Dowels are small, cylindrical wooden pins that are inserted into aligned holes in both mating pieces, adding mechanical strength and helping with alignment. When used with a butt joint, dowels significantly increase the joint’s resistance to pulling forces and improve durability over time. This method is especially useful for edge-to-face or edge-to-edge connections where glue alone might not provide enough holding power. With a bit of careful measuring and drilling, dowels turn a simple butt joint into a much sturdier and more reliable connection.

Learn more about how to make dowel joints.