What are the best ways to join wood?

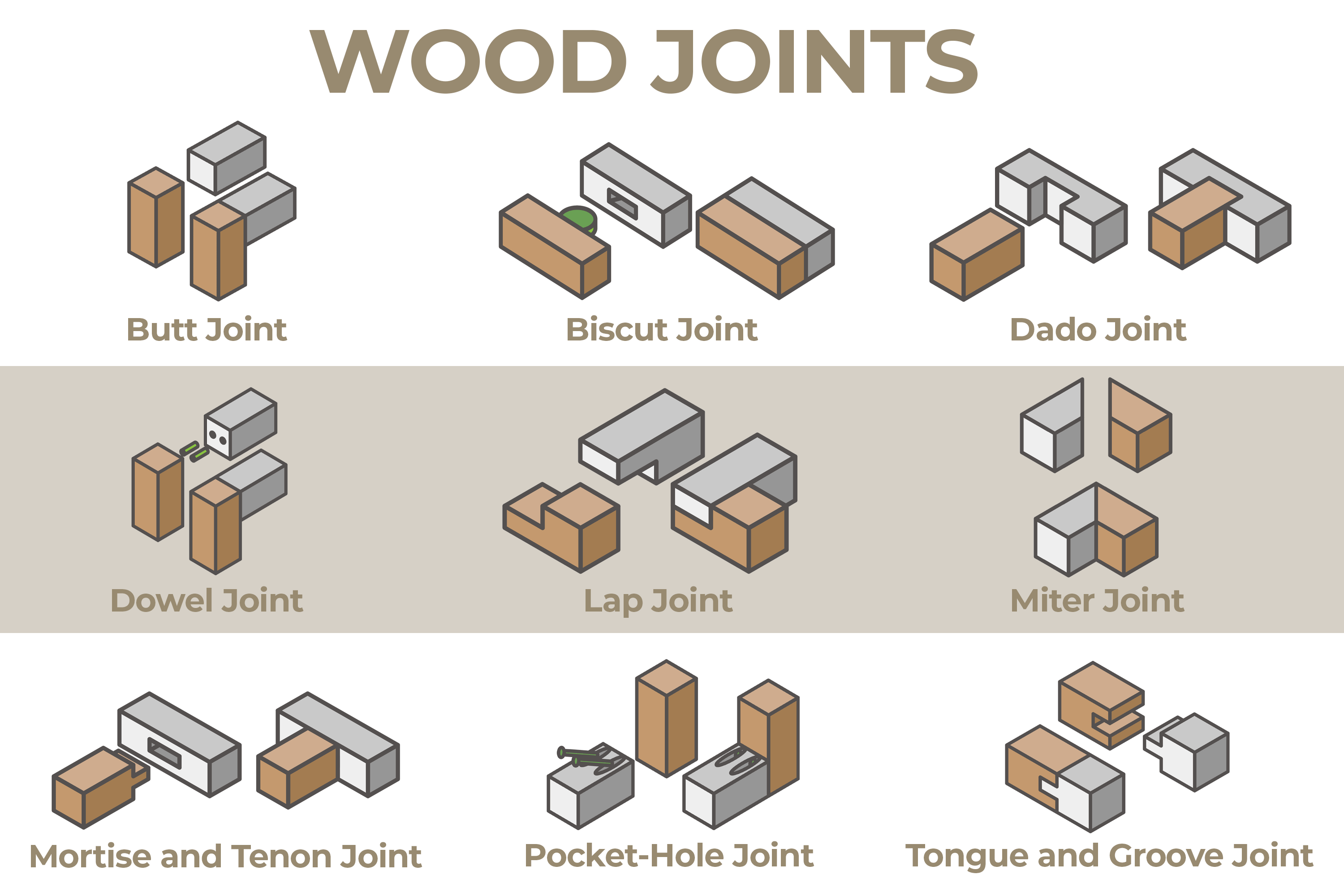

The best ways to join wood include techniques such as butt joints, miter joints, pocket-hole joints, biscuit joints, dowel joints, mortise and tenon joints, dado joints, lap joints, and tongue and groove joints, each with its own set of advantages and disadvantages in woodworking projects.

How do you join wood at 90-degree angle?

Joining wood at a 90-degree angle can be achieved through various woodworking techniques, including miter joints, butt joints, dowel joints, and pocket-hole joints.

What are the basic woodworking joints?

The 9 basic woodworking joints include butt joints, pocket-hole joints, miter joints, biscuit joints, dowel joints, mortise and tenon joints, dado joints, lap joints, and tongue and groove joints.

Let’s explore some of the top methods for joining wood.

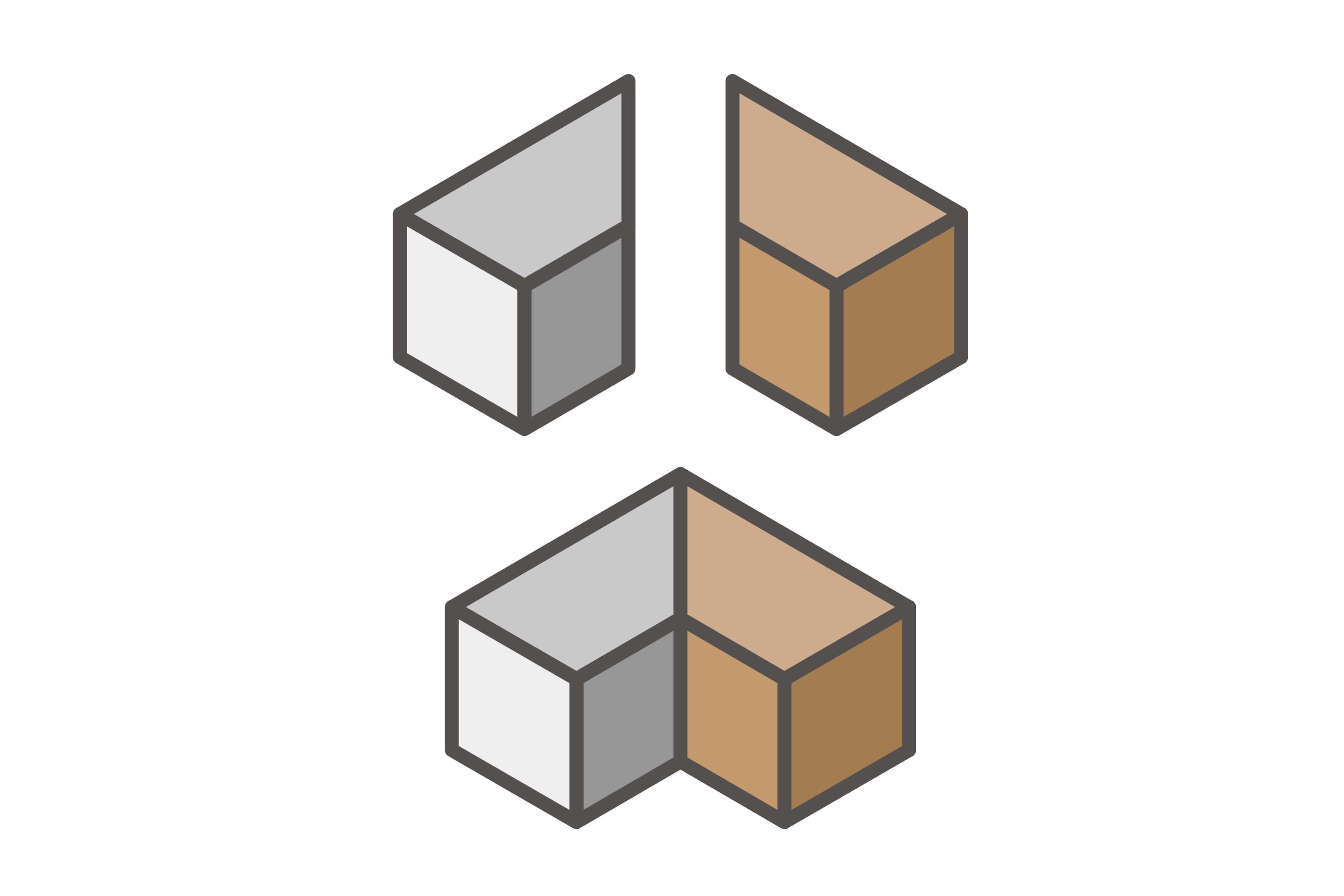

Butt joint

The simplest joint is the butt joint, which involves joining the ends or edges of two pieces of wood to form a right angle. Common methods of reinforcement include the use of glue, screws, nails, dowels or pocket holes.

Pros:

- It’s quick and simple to make, making it great for short and easy tasks.

- Requires minimal tools and equipment.

- Can add screws, nails, or dowels for extra support.

Cons:

- Not very sturdy without reinforcement because of its weak foundation.

- Visible end grain can be aesthetically unappealing.

- At risk of separation under pressure if not reinforced properly.

- Requires extra time waiting for glue to dry.

Miter joint

The miter joint is a corner joint made by cutting the ends of the wood pieces at a 45 degree angle. Reinforcement can be accomplished with glue, nails, splines or pocket holes.

Pros:

- Creates a clean, seamless corner joint without visible end grain.

- Perfect for use as a frame or in a decorative setting.

- Can be reinforced with splines or biscuits for added strength.

Cons:

- Accurate and exact cutting angles are needed for a tight fit.

- Weak compared to other types of joints, especially if only adhesive is used.

- Not as strong as it needs to be for load-carrying or structural uses.

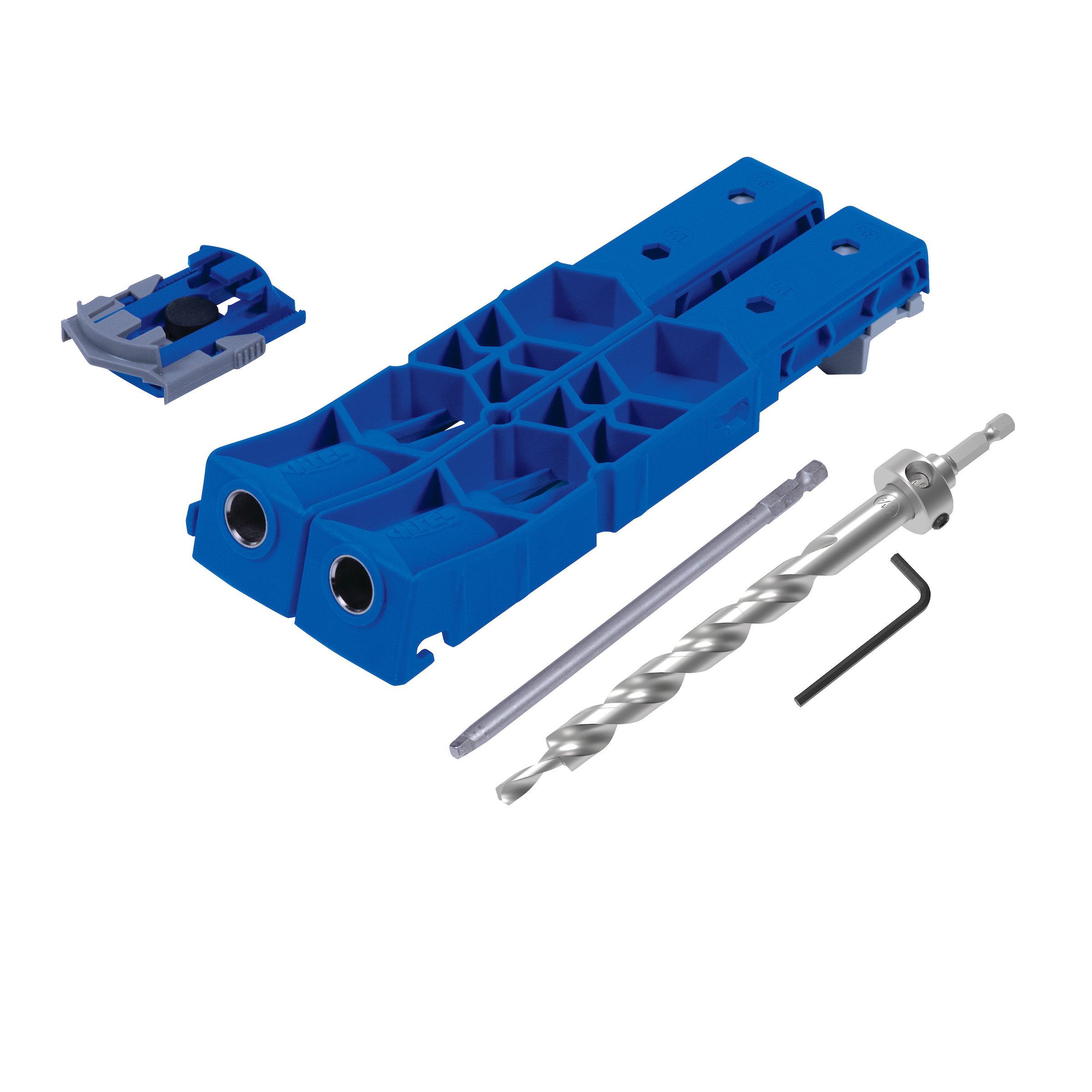

Pocket-hole joint

This popular method involves drilling an angled hole into one piece of wood and using screws to join it with another piece. It’s very simple and provides strong connections.

Pros:

- Makes creating joints fast and simple.

- Increases the durability of the joints.

- Concealed screws make it suitable for visible surfaces.

- Doesn’t require clamping if using glue to add additional strength.

Cons:

Biscuit joint

For a biscuit joint, a slot is cut into both pieces of wood with a biscuit joiner, and an oval-shaped biscuit is inserted with glue to secure the joint and keep it aligned.

Pros:

- Edge-to-edge joints are aligned and strengthened as a result.

- Makes assembly easy and fast.

- Concealed biscuits result in a clean and professional appearance.

Cons:

- Requires precise placement to get accurate results.

- Requires a specialized tool (biscuit joiner) for cutting slots.

- Weaker compared to other joint types, especially under heavy loads.

- Biscuits can swell and cause misalignment if exposed to moisture.

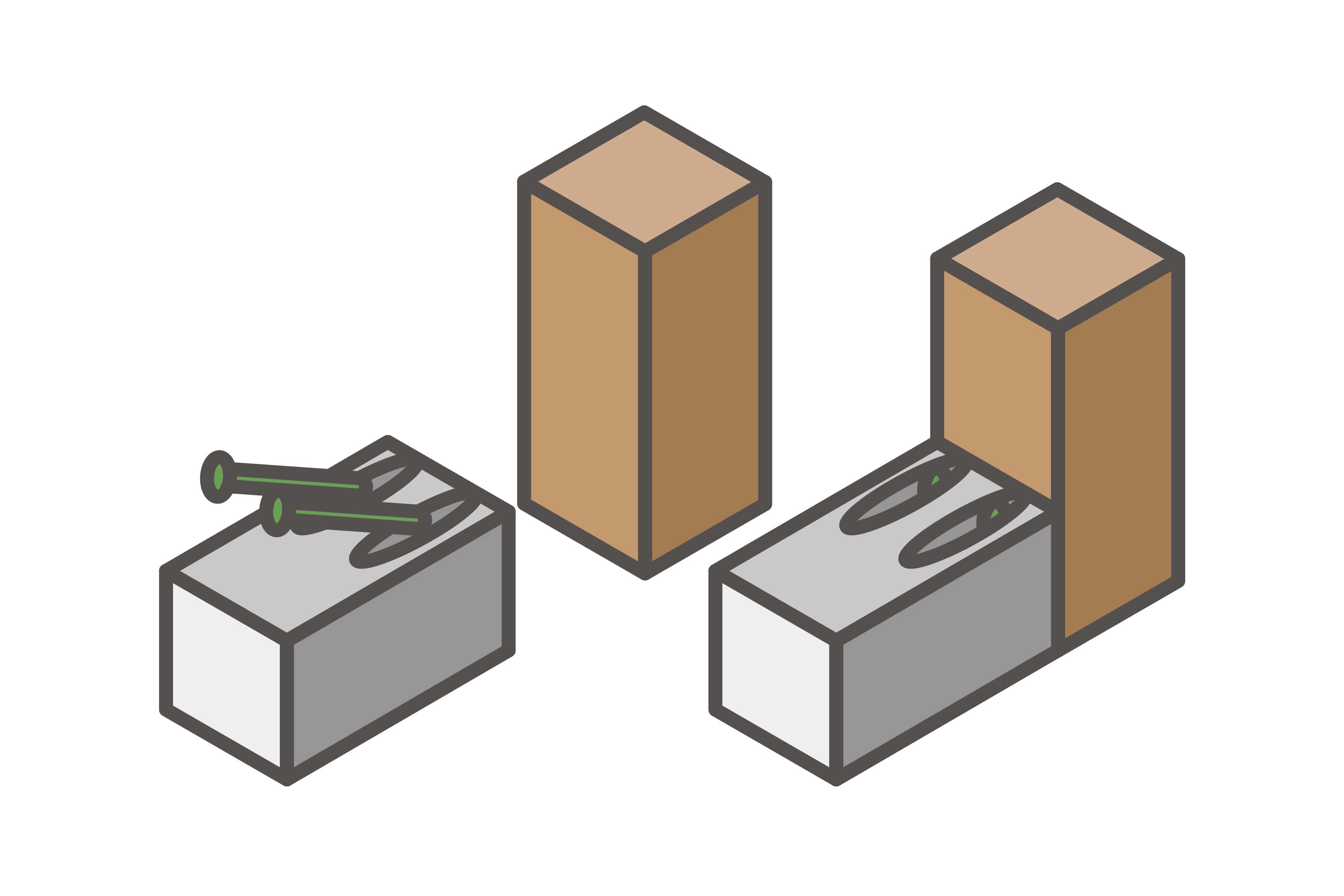

Dowel joint

The dowel joint is a method of aligning and securing a junction between two pieces of wood by drilling corresponding holes in both parts and inserting dowels (cylindrical wooden rods).

Pros:

- Offers good alignment and joint strength.

- Relatively simple and cost-effective to create with basic tools.

Cons:

- Requires precise drilling to ensure accurate alignment.

- Difficult to disassemble once glued.

- Limited strength compared to more complex joinery methods.

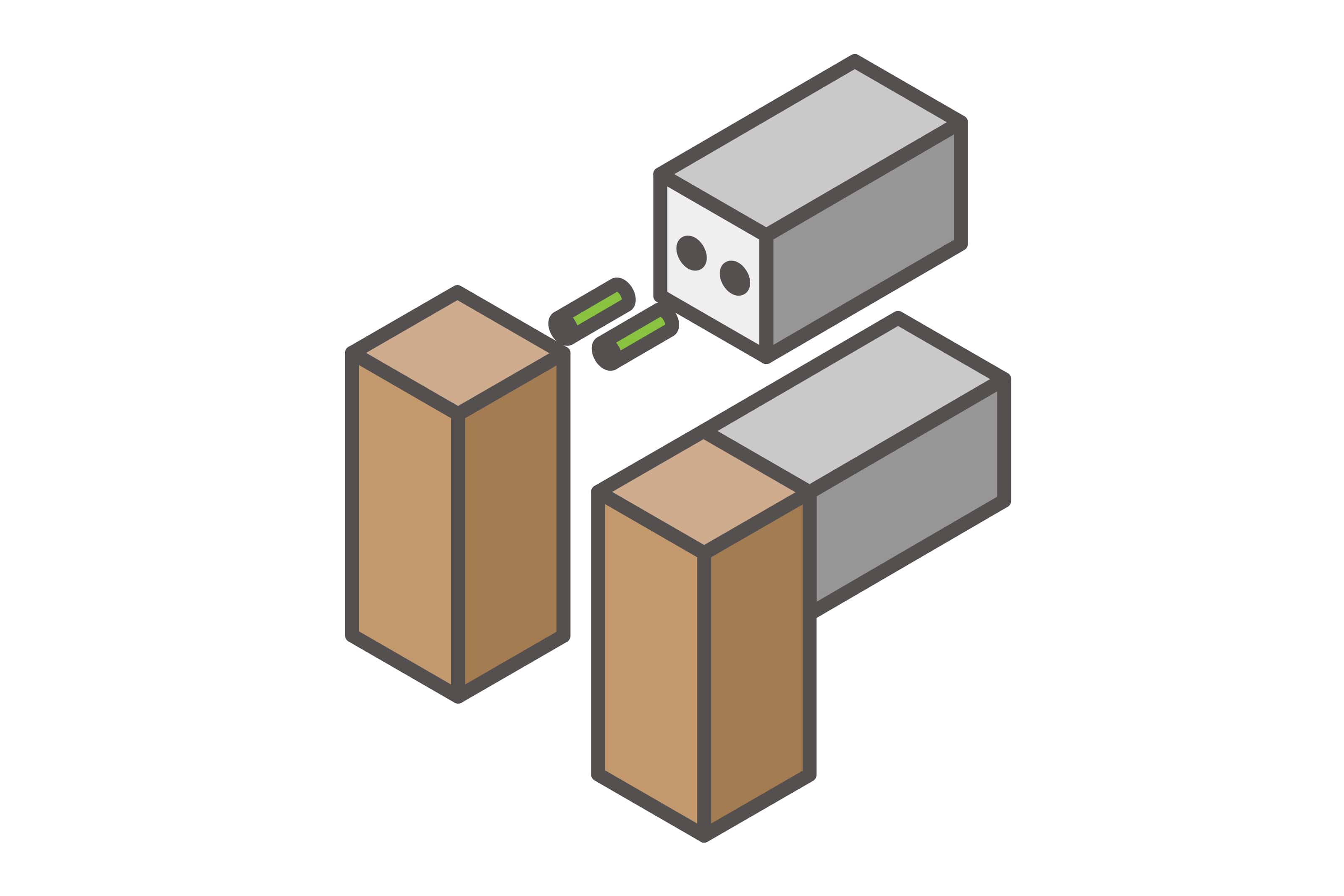

Mortise and tenon joint

A mortise is a square or rectangular hole cut into one piece of wood, and a tenon is a similar protrusion cut into another piece of wood that fits into the mortise.

Pros:

- Considered one of the strongest and most reliable joints.

- Superior strength under pressure; good for use in furniture.

- Offers a tried-and-true style that’s also aesthetically pleasing.

Cons:

- You’ll need more experience and specialized equipment to make it.

- Accurate and precise measurements are required for a snug fit.

Dado joint

The dado joint is a method of making a flush connection between two pieces of wood by routing a groove or channel through one of them.

Pros:

- It makes a solid connection while building cabinets and shelves.

- Provides a larger area for gluing and better alignment.

- Hides the terminal grain for a smoother overall look.

Cons:

- You’ll need a dado blade or router to get the job done.

- Difficult to get a perfect fit without the right tools.

- The workpiece may be weakened if too much material is removed.

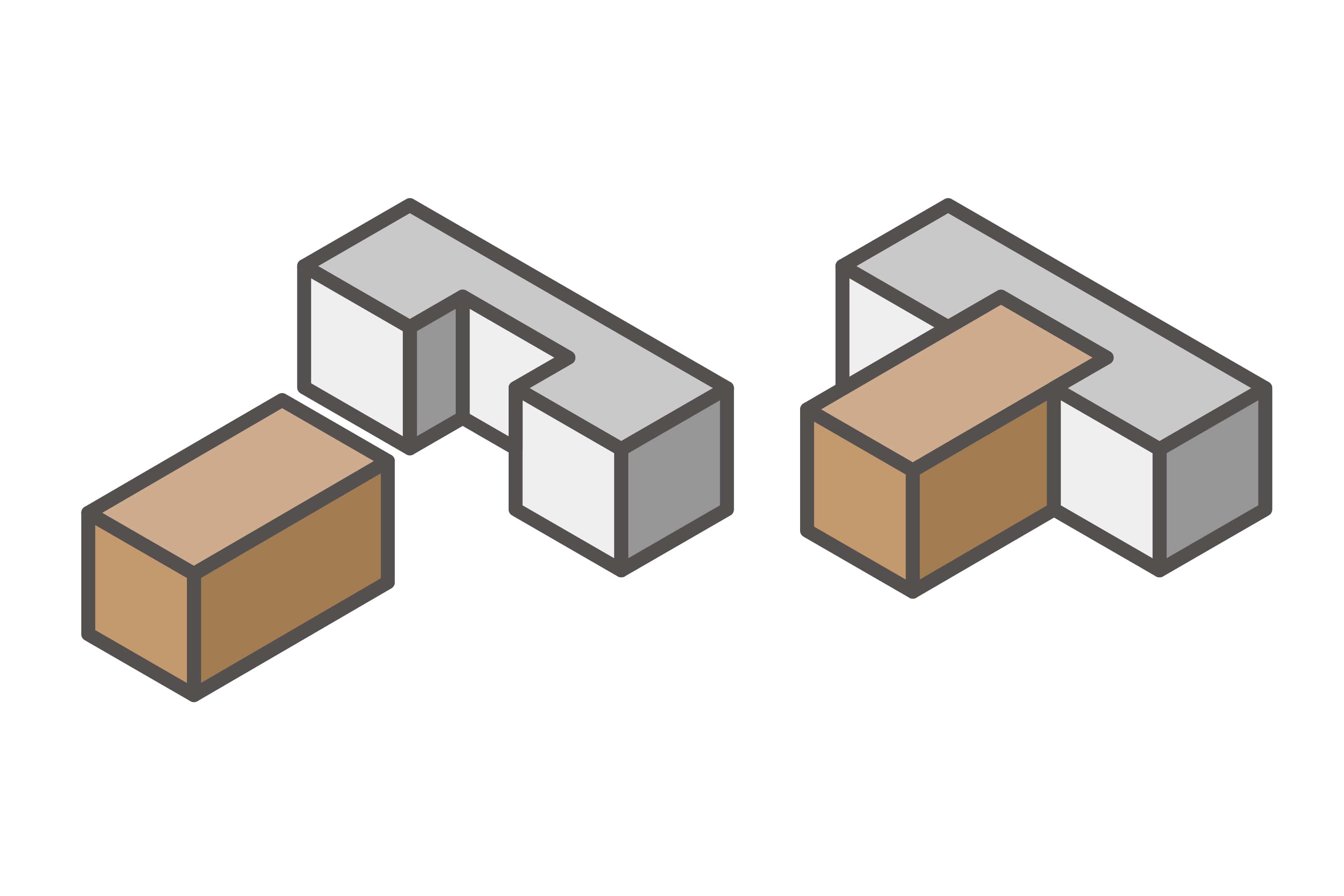

Lap joint

In this method, the two pieces of wood overlap partially, and they can be secured with glue, nails, or screws.

Pros:

- Simple and versatile joint suitable for a variety of applications.

- Provides decent joint strength when reinforced with screws or dowels.

- Allows for fine-tuning and adjustments to be made during assembly.

Cons:

- Not suitable for heavy loads or structural applications.

- The appearance of terminal grain may be undesirable.

- Needs reinforcing to achieve sufficient strength.

Tongue and groove joint

A tongue protrudes from one piece of wood and fits snugly into a groove in the opposing piece, forming a sturdy and attractive junction.

Pros:

- Creates a tight and interlocking joint for panels and flooring.

- Provides excellent stability and prevents warping or movement.

- The end grain is hidden, and the result is aesthetically attractive.

Cons:

- Requires specialized tools that may be costly and inaccessible to some woodworkers.

- Prevents wood from expanding and contracting as it should, which can cause problems like cracking and splitting.

- Can be time-consuming due to the need for precise measurements.

![]()

What is the most popular wood joint?

Despite being the weakest wood joint, the simplest and most commonly used is the butt joint.

Pocket hole joints have become increasingly popular among DIY enthusiasts and woodworking hobbyists. The pocket hole joint involves drilling angled holes and using screws to join pieces of wood together, offering simplicity and strength for various projects. The most popular wood joint varies depending on the application and personal preference.

What is the easiest wood joint?

The butt joint is the simplest joint in wood, but unfortunately, it also happens to be the weakest.

The butt joint’s ease of construction comes from the fact that no specialized tools or expertise are required for its assembly. However, its weakness becomes apparent when considering its structural integrity.

Stability is mostly provided by additional reinforcement (such as screws, nails, or dowels) in the joint. The joint is weak and could separate under stress or pressure if it isn’t reinforced. Additionally, the joint’s strength is diminished because it is produced by combining the end grain of two pieces, which provides a small area for glue to attach to.

What is the weakest wood joint?

The butt joint is the simplest but weakest of the typical wood joints.

The butt joint, in contrast to joints that are held together by interlocking or overlapping mechanisms, is held together largely by adhesives or fasteners. Because of its reliance on external support, it can easily come apart when subjected to pressure. When working with wood, it’s important to know the limitations of the butt joint and look into other joint options for projects that demand greater structural integrity.

Choosing the Right Wood Joint for Your Project

The joint you choose can significantly impact the overall strength, aesthetic appeal, and ease of construction. By understanding the key factors to consider, you can make an informed decision that will lead to a successful and satisfying woodworking experience and a completed project that will stand the test of time.

Joint strength considerations

When it comes to woodworking, the strength of the joint is a primary concern. The joint needs to be able to withstand the stresses and forces that will be placed on it during the lifetime of the project. Some joints, such as the mortise and tenon or the dovetail, are renowned for their exceptional strength and are often used in furniture-making and other high-stress applications. Pocket-hole joints also stand up well to challenging conditions and are suitable for applications

For more on pocket-hole joints, please check out our helpful article.

Aesthetic factors

The visual appearance of the wood joint can also play a significant role in the overall design of your project.

Some joints, like the finger joint or the box joint, can add a unique and decorative element to your work, while others, such as the rabbet joint or the dado joint, may be more subtle and blend seamlessly into the design. Consider the style and aesthetic you’re aiming for and choose a joint that complements the overall look and feel of your project.

Ease of execution

The complexity of executing a particular wood joint can also be a factor in your decision-making process. Some joints, like the biscuit joint or the pocket-hole joint, are relatively straightforward and can be executed with minimal specialized tools or skills. Others, such as the dovetail or the mortise and tenon joint, require more advanced techniques and specialized tools, which may be more challenging for beginner woodworkers.

What is the easiest strong wood joint?

The easiest strong wood joint for beginners is often the pocket hole joint, which involves drilling angled holes and using screws to join pieces of wood together, providing both simplicity and strength for various woodworking projects.

What is the best corner joint for wood?

When it comes to selecting the best corner joint for wood, it often depends on factors such as the intended use, aesthetics, and ease of construction. One popular and versatile option is the pocket-hole joint due to its reliable strength, ease of assembly and concealed fasteners.

Which type of corner joint is the strongest?

While traditional options like dovetail joints excel in strength, pocket-hole joints reinforced with glue can also provide impressive durability and load-bearing capacity.

What is the best way to join wood?

When it comes to attaching wood, pocket-hole joints are among the most popular choices. Pocket-hole joints are now standard in the woodworking industry because of their reliability, durability, and adaptability.

The standout feature of the pocket-hole joint is the simplicity. Woodworkers can quickly and easily manufacture precise angled holes using a pocket-hole jig and a drill. Because of how easy it is to create pocket hole joints, even inexperienced woodworkers and DIYers can benefit from them.

Pocket-hole joints are also exceptionally strong. The angled screws used in pocket holes create a mechanical connection between the joined pieces, resulting in secure and robust joints. This enhanced stability allows pocket-hole joints to withstand heavy loads and stresses, making them suitable for various woodworking applications.

Another benefit is versatility. Pocket holes can be used for joining boards at right angles, fastening face frames, reinforcing miter joints, and numerous other uses. They can also be easily put together and taken apart, making them great for projects that may require future modifications or repairs.