Woodworking, an age-old craft that melds skill with creativity, places a significant emphasis on the precision of wood cutting. As woodworkers embark on projects ranging from intricate furniture pieces to functional cabinets, the way wood is cut becomes a defining factor in the overall quality and aesthetics of the final creation. This comprehensive guide aims to delve deep into the art of woodcutting, shedding light on various cutting techniques that not only meet but exceed the desired outcomes in woodworking projects.

Essential Wood Cutting Tools

Circular Saw

The circular saw, with its whirring blade and versatility, stands as a cornerstone in any woodshop. Its ability to handle a variety of materials, from softwoods to hardwoods, makes it an indispensable tool for woodworkers. Circular saws are equipped to make a range of cuts, each serving a distinct purpose in woodworking.

Table Saw

If the circular saw is the workhorse, the table saw is the maestro of precision in the woodshop. Revered as a primary woodcutting tool, the table saw’s robust build and powerful motor make it the go-to choice for achieving unparalleled accuracy in a variety of cuts. Its capacity for rip cuts, which run parallel to the wood grain, ensures the efficient transformation of large boards into narrower sections, maintaining the integrity of the wood.

Miter Saw

For those seeking precision in angled cuts, the miter saw emerges as a specialized ally. With its pivoting blade and guided accuracy, the miter saw is tailored for creating joints and corners with a level of accuracy that surpasses general-purpose saws. The miter saw’s proficiency in making miter cuts, where the blade is angled across the face of the wood, ensures seamless connections in projects where precision matters most.

Hand Saw

Among the hum of power tools, the hand saw maintains its relevance in the woodworker’s toolkit. A variety of hand saws, each with a specific purpose, provide woodworkers with a level of control and finesse that complements the efficiency of power tools.

What is the Best Tool for Cutting Wood?

The best tool for cutting wood depends on the specific task, but a versatile and fundamental tool for many woodworking projects is the table saw, which offers precision and a variety of cutting options.

What is the Most Versatile Woodcutting Tool?

Jigsaw

The most versatile woodcutting tool is the jigsaw, known for its ability to make intricate curved cuts, straight cuts, and even plunge cuts, making it essential for a wide range of woodworking applications. Circular saws, while they don’t make the same kinds of cuts as jigsaws, are loved by many woodworkers and DIYers who consider them great all-around tools that can make nearly any cut, though often with the aid of cutting guides.

Common Types of Wood Cuts

Crosscut

The crosscut, a fundamental woodcutting technique, involves making a straight cut across the grain of the wood. This technique is foundational, serving as the initial step in transforming raw lumber into usable pieces for woodworking projects. Crosscuts are essential for creating pieces of specific lengths and preparing wood for further shaping and detailing. Achieving clean and precise crosscuts requires attention to blade alignment, proper marking, and steady control of the cutting tool. Circular saws and table saws excel in executing crosscuts with efficiency.

Rip Cut

Rip cuts run parallel to the wood grain, transforming wide boards into narrower sections. Table saws, equipped with rip fence systems, emerge as the tool of choice for executing rip cuts with precision. Achieving straight rip cuts usually requires proper alignment of the rip fence, selection of an appropriate blade, and a steady feed rate on a table saw. Edge guides enable circular saws to get straight rip cuts.

Miter Cut

Miter cuts introduce angles into the woodworking equation, allowing woodworkers to create corners and joints that fit seamlessly. The miter cut involves angling the blade of the saw across the face of the wood, creating precise angles that contribute to the overall aesthetics and functionality of a project. Miter saws, designed with pivoting capabilities, become instrumental for accurate miter cuts. Understanding the saw’s features, including bevel and miter adjustments, determines the success of this cutting technique.

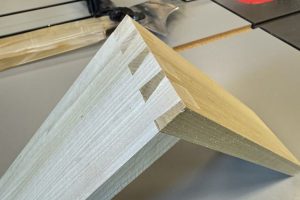

Bevel Cut

Bevel cuts involve tilting the saw blade to create angled edges along the thickness of the wood. This technique adds a dynamic element to woodworking, allowing for the creation of beveled edges and unique shapes. Bevel cuts are versatile, finding applications in crafting decorative edges, chamfers (symmetrical sloping surfaces at an edge or corner), and creating dynamic profiles for various woodworking elements. Achieving precise bevel cuts requires an understanding of the tool being used, whether it’s a circular saw, table saw, or miter saw. Woodworkers must consider the angle of the bevel, the depth of the cut, and the wood species to ensure the desired result. Bevel cuts, when executed with finesse, contribute to the visual appeal and design of a woodworking project.

Advanced Cutting Techniques

Dado Cut

Dado cuts involve creating a wide, flat-bottomed groove or trench across the wood. This technique finds applications in joinery, creating channels for shelves, and accommodating panels in cabinet construction. Dado cuts contribute to the stability of joints and connections, ensuring a robust final product. Executing dado cuts involves precision in marking, setting up the cutting tool, and controlling the depth of the cut.

Rabbet Cut

Rabbet cuts are similar to dado cuts but are made along the edge of the wood rather than its face. This technique involves removing a portion of the wood to create a step or recess. Woodworkers leverage rabbet cuts in projects where seamless connections are crucial, such as constructing boxes, drawers, or cabinets. Achieving precise rabbet cuts requires attention to detail in marking, configuring the cutting tool, and ensuring clean and accurate removal of the wood material. Rabbet cuts contribute to the overall aesthetics and functionality of woodworking projects, exemplifying the marriage of form and function.

Joinery Cuts (Dovetail, Mortise And Tenon)

The hallmark of craftsmanship in woodworking lies in the mastery of joinery cuts. Joinery, the art of creating strong and durable connections between pieces of wood, requires precision and skill in executing specific cuts that stand as testaments to a woodworker’s expertise.

Dovetail Cut

Dovetail joints are revered for their strength and visual appeal. This joinery cut involves creating interlocking wedge-shaped tails and pins, forming a connection known for its resistance to pulling forces. Dovetail joints are often seen in drawers, cabinets, and high-end furniture pieces. Making dovetail cuts demands precision in marking, cutting, and fitting the pieces together. Woodworkers often use specialized tools such as dovetail saws and chisels to create the intricate geometry of dovetail joints.

Mortise and Tenon Cut

Mortise and tenon joints, known for their simplicity and strength, involve creating a cavity (mortise) in one piece of wood that perfectly accommodates a projecting piece (tenon) from another. This timeless joinery cut is widely used in furniture making, framing, and structural woodworking. The process of executing mortise and tenon cuts requires precision in measuring, marking, and cutting to ensure a snug fit between the components. Woodworkers may employ tools such as mortising machines, chisels, and tenon saws to achieve the necessary accuracy.

Choosing the Right Woodcutting Techniques for Projects

The journey of a woodworking project begins with envisioning the final piece and progresses through meticulous planning. Selecting the right woodcutting techniques is a crucial aspect of this planning phase, determining not only the efficiency of the workflow but also the ultimate success of the project.

Guidance on Selection

Guidance on selecting the appropriate cutting techniques based on project requirements involves considering factors such as wood type, project size, and desired outcomes. Each woodcutting technique brings its own set of advantages and considerations, and woodworkers must tailor their approach to meet the demands of each project.

Wood Type

Different wood species possess unique characteristics, including hardness, grain patterns, and density. Understanding these attributes is essential when choosing the right cutting techniques. For example, hardwoods may require specialized blades and cutting methods to achieve clean and precise results, while softwoods may be more forgiving in certain applications.

Project Size

The scale of the project influences the choice of cutting techniques. Larger projects, such as building furniture or cabinets, may involve a combination of basic and advanced cutting techniques to create various components and join them seamlessly. Smaller projects, like crafting intricate details or decorative elements, may demand precision in specific cuts.

Desired Outcomes

Consideration of the desired outcomes plays a pivotal role in selecting cutting techniques. If the project calls for visible joinery, dovetail, or mortise and tenon cuts may be the preferred choice. For projects where clean edges and smooth surfaces are paramount, techniques such as crosscutting, rip cutting, and planing are preferred.

Safety Tips for Wood Cutting

While the focus is often on the mastery of cutting techniques, the importance of safety in woodworking cannot be overstated. Woodcutting tools, with their sharp blades and powerful motors, demand a heightened level of awareness and adherence to safety guidelines.

Importance of Safety Measures

The workshop environment presents inherent risks, and woodworkers must prioritize safety to mitigate potential hazards. Safety measures include a range of practices, from personal protective equipment (PPE) to the proper setup and operation of cutting tools.

PPE (Personal Protective Equipment)

Woodworkers should consistently use appropriate PPE to safeguard themselves during woodcutting activities. This includes safety glasses or goggles to protect the eyes from debris, hearing protection to mitigate the impact of prolonged exposure to the noise generated by cutting tools, and dust masks or respirators to prevent inhalation of fine wood particles. Hearing protection is essential, especially when operating loud tools like table saws or routers, to prevent potential hearing damage over time. Additionally, dust masks or respirators serve to protect from inhaling wood dust, which can contain harmful particles and contribute to respiratory issues. Proper attire, including sturdy work gloves and closed-toe shoes, adds an extra layer of protection against accidental cuts and injuries.

Troubleshooting Common Cutting Challenges

Even experienced woodworkers encounter challenges in the cutting process. Identifying common issues, from blade selection to technique execution, and implementing effective solutions, is essential for overcoming obstacles and achieving better results. Some common challenges include tear-out during crosscuts, blade deflection during resawing, and misalignment in joinery cuts. Addressing these challenges with informed solutions enhances the overall woodworking experience.