Discover a new contender against the table saw and miter saw

Cutting is a big part of building wood projects. Most people think of the table saw and miter saw as the go-to tools for this, but Kreg offers another option: The Adaptive Cutting System. Take a look at how you can use the Adaptive Cutting System to make all your cutting tasks easier — whether you’re using dimensional boards, hardwoods, or plywood.

How is the Adaptive Cutting System different?

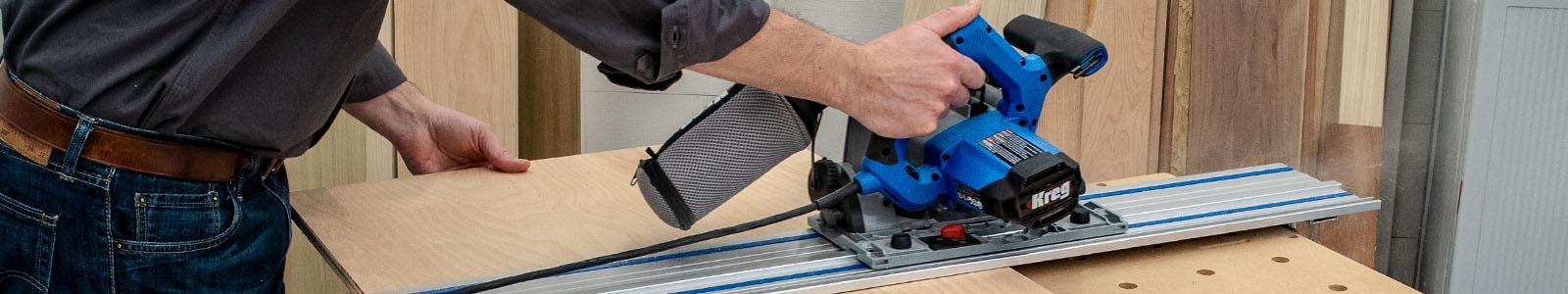

The Adaptive Cutting System definitely looks different than a table saw or a miter saw, and it is different. The Adaptive Cutting System is based on a special type of circular saw called a plunge saw, also known as a track saw. The saw and 62″ Guide Track work together to provide straight, accurate, splinter-free cuts.

With the Adaptive Cutting System, though, the Plunge Saw and Guide Track are just part of the story. What really differentiates this system is the Project Table. This large table supports workpieces as you cut, and it has integrated measuring systems and stops that allow you to make a variety of cuts.

Plunge Saw:

The Plunge Saw has some unique features, and is designed to work with a Guide Track

- Shrouded Blade: Plunges into material as you cut. Retracts completely at end of cut.

- Riving Knife: Protects against kickback by following the blade to prevent the saw kerf from closing up and pinching the blade.

- Splinter Guard: Minimizes tear-out on side of blade that’s not against track, resulting in a smooth cut.

- Depth-of-Cut Adjustment: Determines how far the blade will plunge to cut through.

- Bevel Scale: Adjusts from -1° to 47° for making precise bevel cuts.

- Dust Collection: Captures up to 85% of sawdust to eliminate cutting mess.

- Soft Start, Blade Brake: Prevents jolting at start of cut, stops blade quickly at end of cut.

- Anti-Kickback Protection: Selectable to prevent saw from moving backwards while cutting.

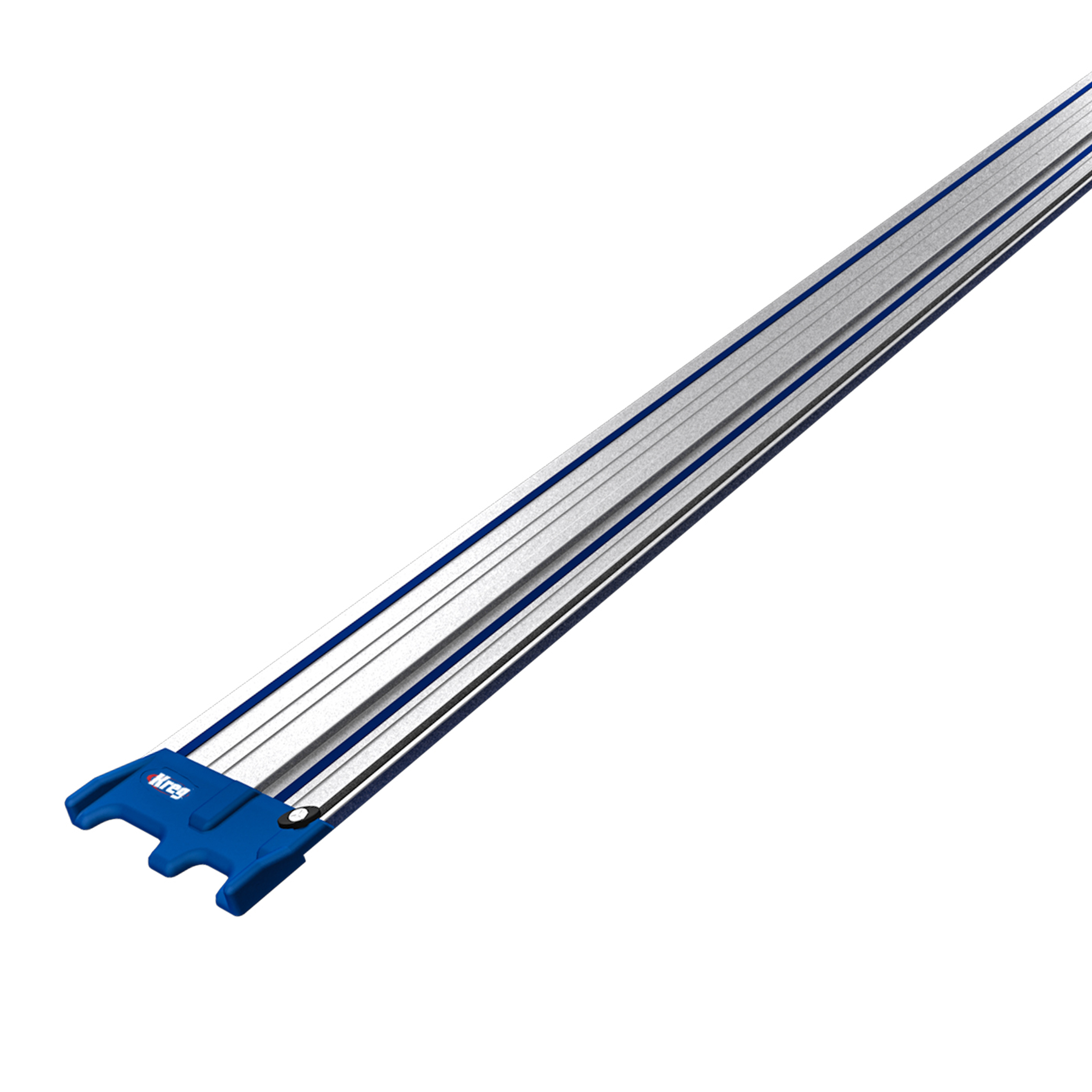

62″ Guide Track

Made from durable aluminum, the track guides the Plunge Saw straight as you push the saw along the track.

- Anti-Chip Strip: Hugs tight against Plunge Saw blade to virtually eliminate tearout.

- Anti-Slip Strips: Strips under the track grip material being cut to hold track in place without clamps.

- Zero-Offset Design: Edge of anti-chip strip aligns with cutline for simple setup.

- Versatile Design: Guide Track can be used on or off the Project Table, can be paired for longer cuts.

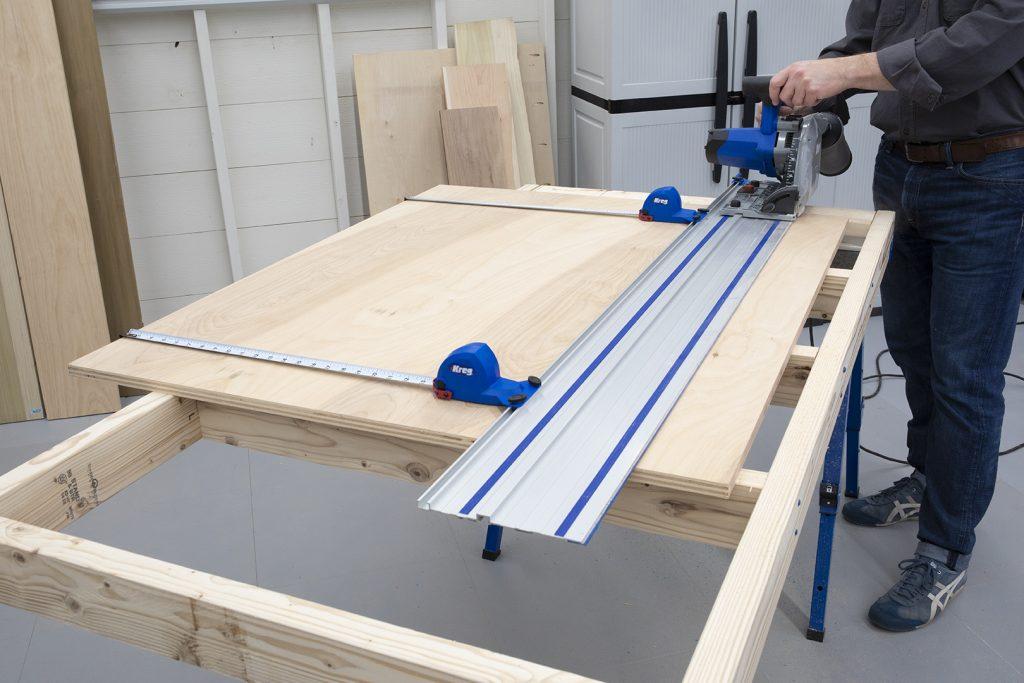

Project Table

This versatile table turns the Plunge Saw and Guide Track into a portable, multipurpose cutting center that adapts to your cutting needs.

Table Top

Large 55″ x 29 3/4″ surface supports plywood sheets and boards while cutting.

Precision-Machined Holes

Accept included Versa-Stops for exact material positioning during crosscuts, rips, and miters.

Measuring Scales and Repetitive Stops

Integrated precision rules and Repetitive Stops accurately measure from 0″ to 25″ to ensure accurate, repeatable cuts.

Track Hinges

Hinges locate the Guide Track precisely and make it easy to position materials.

48″ Extension Bar

Provides precision measuring for workpieces larger than the width of the Project Table — up to 48″.

Miter Guide

Holds workpieces at angles from 0° to 60° for accurate miter cuts.

Steel Stand

Sturdy stand provides a solid work surface, then folds for easy rolling and storage of the Adaptive Cutting System.

Side-by-side comparison: Crosscutting capabilities

Cutting boards to length — crosscutting — is one of the most essential cuts for building woodworking and DIY projects. Both a table saw and a miter saw can make crosscuts, but each has some shortcomings. The design of the Adaptive Cutting System overcomes those to make crosscutting easier.

Support for long pieces

The Adaptive Cutting System easily supports long pieces on the Project Table. The table’s built-in stops, combined with the anti-slip strips on the underside of the track, holds boards precisely in place while you cut. The Anti-Chip Strip on the Guide Track ensures that your crosscuts will be smooth and splinter-free, too.

Miter saw

Miter saw tables are not very long, so boards more than a few feet long hang over. Without added support, the part of the board you’re not holding can fall after the cut.

Table saw

Table saws offer a larger surface, but even then, longer pieces can drag and be hard to control when using the miter gauge.

Adaptive Cutting System

The Project Table supports long pieces. Integrated stops, combined with the anti-slip strips on the track, hold boards in place while you cut. The Guide Track Anti-Chip Strip ensures smooth, splinter-free crosscuts.

Integrated Measuring

Most miter saws and table saws don’t have integrated measuring systems for crosscutting, which means you have to mark and measure every cut, and then align your cut mark with the blade. The Adaptive Cutting System offers real advantages thanks to its built-in measuring.

Miter saw

On the miter saw, you need to mark cut length on the face of the board, positioning the mark where the blade will enter the wood.

Table saw

On a table saw, you need to mark cut length on the edge of the board nearest the blade. This can be tough to see as you align to the blade.

Adaptive Cutting System

The Adaptive Cutting System’s measuring scales and Repetitive Stops eliminate measuring and marking. Simply lock one of the Repetitive Stops down at the exact length you need. Then you can crosscut accurately, whether you’re making one cut at that length or many.

Exact 90° Angles

When cutting boards to length, it’s critical to make a straight, square cuts. A miter saw, a table saw, and the Adaptive Cutting System can all do this in different ways.

Miter saw

A miter saw does a good job of ensuring a square cut by holding the board tightly against the fence.

Table saw

A table saw relies on the miter gauge, which can be small and far from the blade. This makes it tough to hold the board square as you move it past the blade.

Crosscutting wide boards

When it comes to crosscutting wide boards, both the miter saw and the table saw can quickly run out of capacity. That can limit your ability to work with wide stock. The Adaptive cutting System makes it easy to work with wide boards.

Miter saw

Miter saws can quickly run out of cutting capacity, unless you have a big saw with a sliding cutting head. Even then, boards wider than a 1×12 are tough.

Table saw

On a table saw, wide boards are challenging because there’s not much table in front of the blade. To cut a wide board, you’d have to pull the miter gauge off the table, which can cause it to bind and create a potentially dangerous cut.

Adaptive Cutting System

Crosscutting width isn’t limited on the Adaptive Cutting System. Anything up to 48″ wide can be placed on the Project Table under the Guide Track, so you have the ability to crosscut the widest boards you can find.

Side-by-side comparison: Ripping boards

When you’re ready to expand your project possibilities beyond the set widths of dimensional lumber, you’ll want the ability to rip boards to custom widths. A miter saw can’t rip cut at all. A table saw certainly can, but it doesn’t offer a table surface large enough to support long boards.

Support through the entire cut

The Adaptive Cutting System allows you to rip long and short boards accurately and safely, which opens up new worlds of project possibilities.

Table saw

A table saw fence makes ripping easy, but the table leaves a lot to be desired. On the infeed side, there’s not much room. On the outfeed side, boards don’t have much support, which makes them much harder to control. This lack of table space can cause boards to fall, and it can be very unsafe if you try to grab them.

Adaptive Cutting System

The Adaptive Cutting System Project Table supports boards of any width up to 48″ long while you rip. The board remains stationary, so you don’t have to control it. Just move the saw over the board for a straight, safe rip. Plus, the Repetitive Stops can lock in measurements from 1″ to 25″ wide, so you can rip any board and get a smooth, straight, splinter-free cut.

Advanced Ripping Capabilities

The Adaptive Cutting System makes it possible to rip boards that may be challenging to work with on the table saw.

You can rip boards as short as a few inches long using the Joining Bar that fits between the Repetitive Stops. The integrated stops and the track’s anti-slip surface hold the board solidly in place while your hands stay on the saw, nowhere near the blade.

You can easily rip a rough or crooked edge off any board to create a smooth, straight edge. This makes it possible to work with more types of boards that are sold by woodworking retailers.

Side-by-side comparison: Working with sheet goods

Plywood is a great material for building projects but cutting plywood can be a real hassle. You can’t cut plywood with a miter saw. And wrestling large, heavy plywood sheets on a table saw is difficult at best and a real safety challenge at worst.

Serious sheet-cutting capacity

The Adaptive Cutting System will change the way you think about cutting plywood. The straight, accurate, and smooth cutting of the Plunge Saw and Guide Track combine with the support and integrated measuring of the Project Table to make plywood cutting a breeze.

Table saw

On a table saw, plywood sheets hang over the table as you cut. This makes it hard to hold them against the rip fence for accuracy, and means the pieces are hard to control.

Adaptive Cutting System

The Project Table supports full and partial sheets, and it holds them securely in. Using the built-in measuring scales, you can easily cut a full sheet of plywood accurately in half, and rip or crosscut smaller pieces.

You can remove the Guide Track from the table to cut larger pieces, combine two Guide Tracks together to rip full sheets, and add accurate measuring with Rip Guides and Parallel Guides.

Side-by-side comparison: Cutting miters

When you’re building projects, some kinds of cuts can be less-than-perfect without really being noticeable. Miter cuts, though, need to be dead-on, or the gaps will show up and look bad. Miter saws and table saws can both cut miters, of course, but so can the Adaptive Cutting System.

Two accurate ways to cut miters

The Adaptive Cutting System makes cutting miters at 45° — the most common miter angle — easy. The same Versa-Stops that position boards at 90° during crosscuts can be positioned at exactly 45° to the track using the holes machined in the project table. For angles other than 45°, simply slide the miter guide onto the table, lock in the angle, and then position your workpiece against the guide for an accurate, smooth miter cut.

Miter saw

Cutting miters one of the main things a miter saw is meant to do. The built-in scale allows easy angle setting. Long boards can be a bit of a challenge to keep in place as you cut.

Table saw

Using the miter gauge, you can cut miters on a table saw. The distance from the miter gauge to the blade can make board control and cut accuracy more challenging to achieve.

Adaptive Cutting System

Versa-Stops can be positioned to hold boards precisely position at 45° to the blade. That makes the cutting angle accurate, while the Anti-Chip Strip ensures a smooth, clean cut.

Adaptive Cutting System

When you need to cut miters that aren’t 45°, use the included miter guide. Set it to cut any angle from 0° to 60°.

Side-by-side comparison: Portability and storage

Whether your workspace is a temporary spot in the driveway, shared area in the garage, or a dedicated workshop, having tools that are easy to move around is a must.

Real-world portability

The Adaptive Cutting System is truly portable. It was designed to be easy to move around, and has large wheels for the table, plus a convenient carrying bag for other components. That means you can set up or stow away the Adaptive Cutting System in just a couple minutes to maximize the time you spend working—wherever you want to work.

Miter saw

Miter saws are portable, for sure, but their design and size makes them awkward to carry. Miter saws can also be tough to store, since they’re too large for most standard shelves.

Table saw

There are well-made benchtop table saws available, but they’re still tough to tote around. A larger table saw usually becomes a big, stationary object that the rest of your workspace has to revolve around.

Adaptive Cutting System

The Adaptive Cutting System Plunge Saw and accessories store in a durable padded bag. The Project Table folds and rolls on large wheels. This means you can store your system in a small area. When you’re ready to work, simply roll it into place, and then flip down the sturdy legs. The measuring scales, track position, and saw setup will be ready to make precise, accurate cuts without the need for checking setups.

When you look the capabilities built in to the Adaptive Cutting System, it’s easy to see how it makes a great alternative to traditional cutting with a miter saw or table saw. The Adaptive Cutting System is versatile and precise. It’s designed to keep your hands away from the blade and to securely hold your materials, so you can work with the confidence of knowing that you can cut safely. Add in portability, and you have a cutting system that truly adapts to your needs.