Tic Tac Toe Board

By Making ManzanitaMake this giant magnetic tic tac toe board for the wall to keep the kids (and adults) entertained for hours!

Directions

-

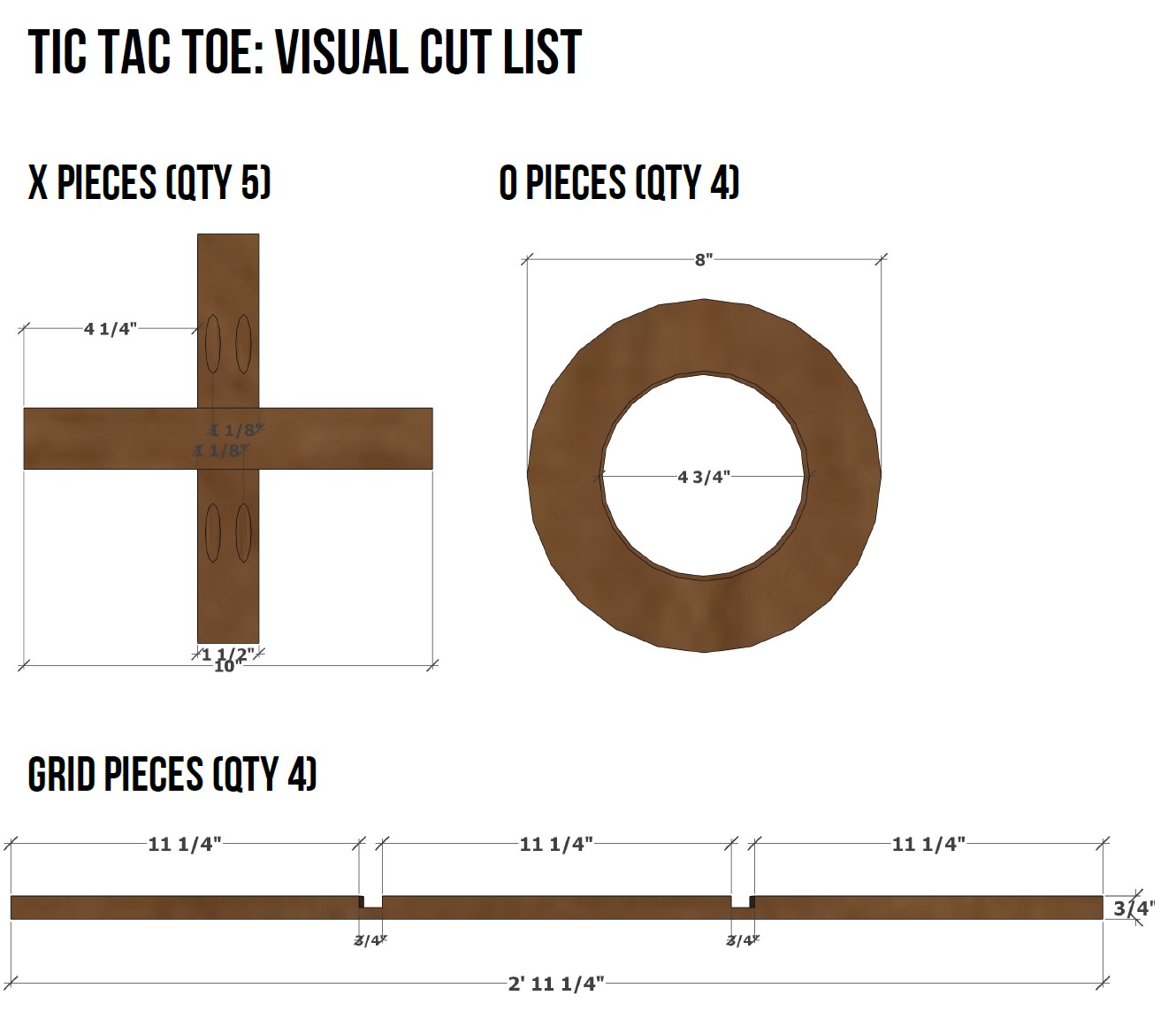

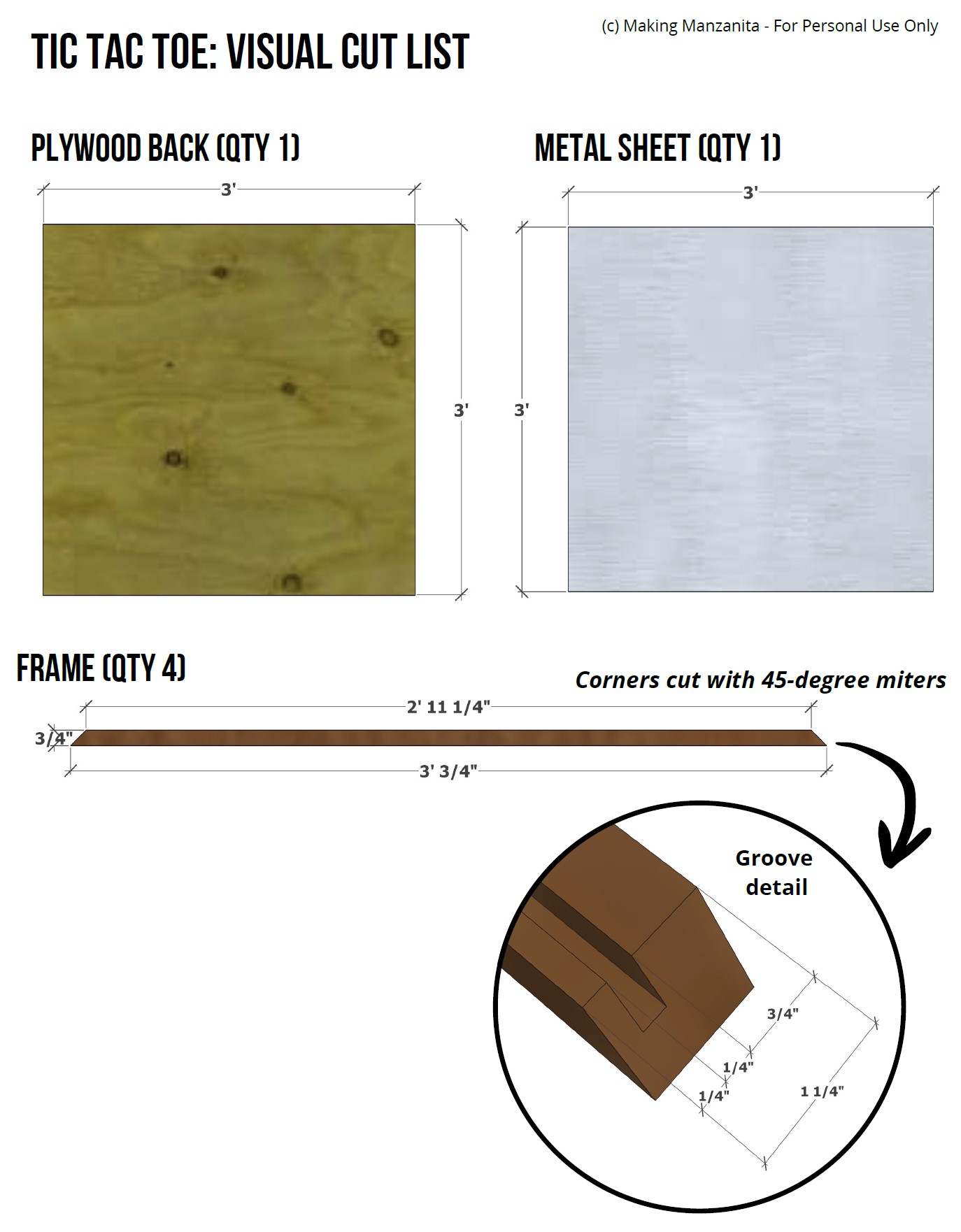

Cut wood

Cut the wood down to size according to the visual cut list in the woodworking plans. We used the Rip-Cut to cut down the sheet of plywood to size and a miter saw to cut the lengths of the boards. We used a table size to cut the grid pieces down and to cut the groove on the inside of the frame.

-

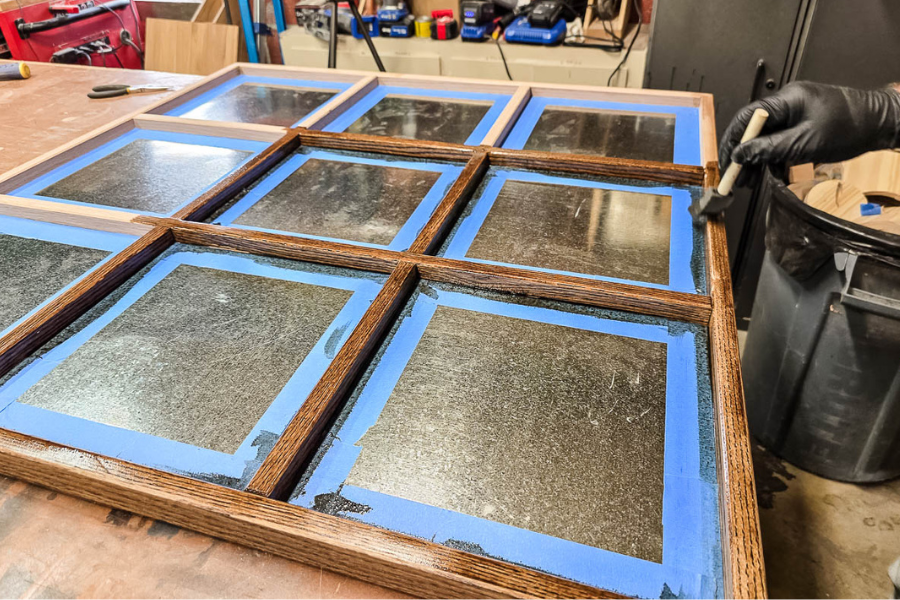

Attach the metal sheet

Lightly sand one side of the sheet of metal with coarse-grit sandpaper and wipe to clean. This will give the metal a texture so the adhesive can grip it when you attach it to the plywood sheet. Apply construction adhesive to the 3x3 plywood sheet, trowel it with a v-notched trowel, and press the metal sheet into place, lining up one edge. Use a rag over a block of scrap wood to press the metal down uniformly. Let dry. After it has dried thoroughly, the excess metal that is hanging over one side can be trimmed down with tin snips.

-

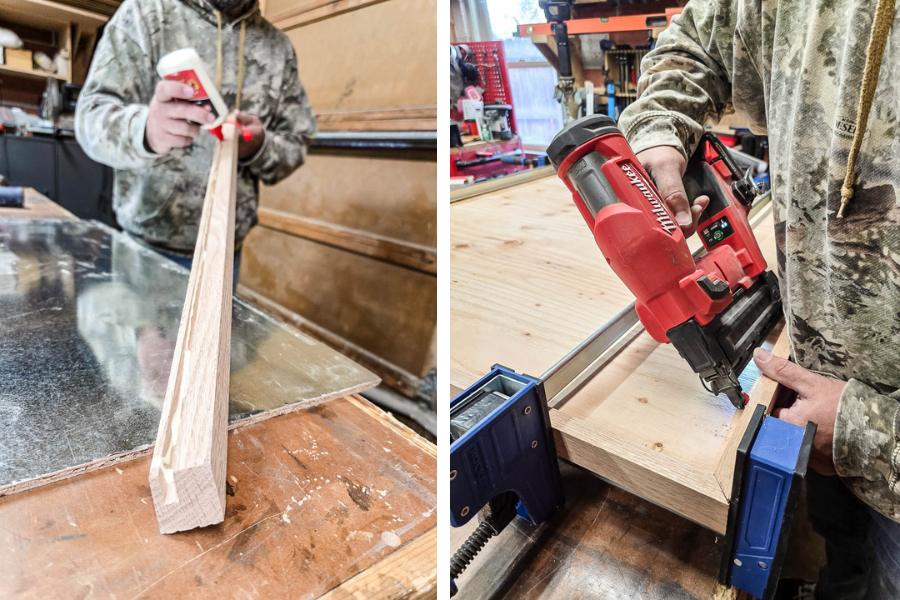

Attach frame

Apply wood glue to the inner edge of the groove and push it into place over the edges of the plywood and metal sheets. Tap into place with a rubber mallet if needed. Clamp into place and nail from the inside edge on the back (plywood side, not metal side) with a brad nail gun and ¾” brad nails. Use 1 ¼” brad nails on the mitered corners of the frame. Let dry.

-

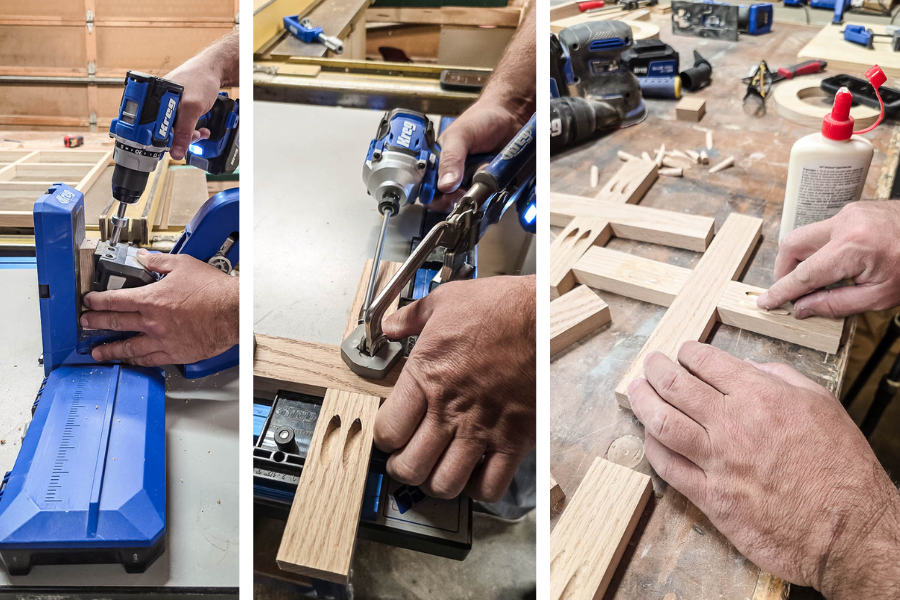

Route out grooves on grid pieces

We are using a cross-lap joint to connect the grid pieces so they interlock. Mark your wood where you want the groove made and clamp down a piece of scrap as a guide for your router. Using a ½” straight router bit, cut a ⅜” deep groove. Repeat on the intersecting board on the opposite side, so they interlock together.

-

Chamfer edges of frame and grid pieces

Using the Kreg trim router and a chamfer bit, chamfer all of the edges of the frame and the grid pieces to make them smoother and more professionally looking.

-

Attach grid pieces together

Add wood glue to the inside of the grooves and attach the grid pieces together. You can put the entire grid inside the frame (on the metal side) to make sure everything is squared up before you secure. Once it is square, nail the interlocking joints with a pin nailer and ¾” pin nails. Use 1 ⅜” pin nails to secure the grid to the frame from the outside edge.

-

Attach grid to frame

Set the grid into place on the frame and nail from the outside of the frame with a pin nailer and 1 ⅜” pin nails.

-

Make X pieces

Drill pocket holes as shown in the woodworking plans on the X’s. We’re using the 720Pro jig. Clamp down on a flat surface and drive pocket hole screws to secure X’s. Then sand smooth with 150-grit sandpaper. Fill pocket holes with plugs and wood glue, and let them dry. Fill any gaps with wood putty and let it dry. Come back once dry and sand smooth to remove excess plugs and wood putty. Lastly, chamfer edges with a router.

-

Make O pieces

On the project panel (or sheet good), make a 4 ¾” diameter circle and an 8” diameter circle on the board with a compass. Then, use a jigsaw, carefully cut out the O pieces. Sand smooth with 150-grit sandpaper. Finish them up by chamfering the edges with a router.

-

Stain and seal

Stain the wood with the color of your choice. We used Dark Walnut for the board and X’s and painted the O’s with white spray paint. Seal everything with several light coats of spray lacquer and let it dry.

-

Attach magnets

Using a drill press, drill a hole in the back of the X’s and O’s the same size as your magnets, about 1/16” deep, so the magnet will be slightly inset. Next, attach the magnets. We added a little silicone to help adhere them.

-

Hang on wall

Hang on the wall with a metal French cleat.