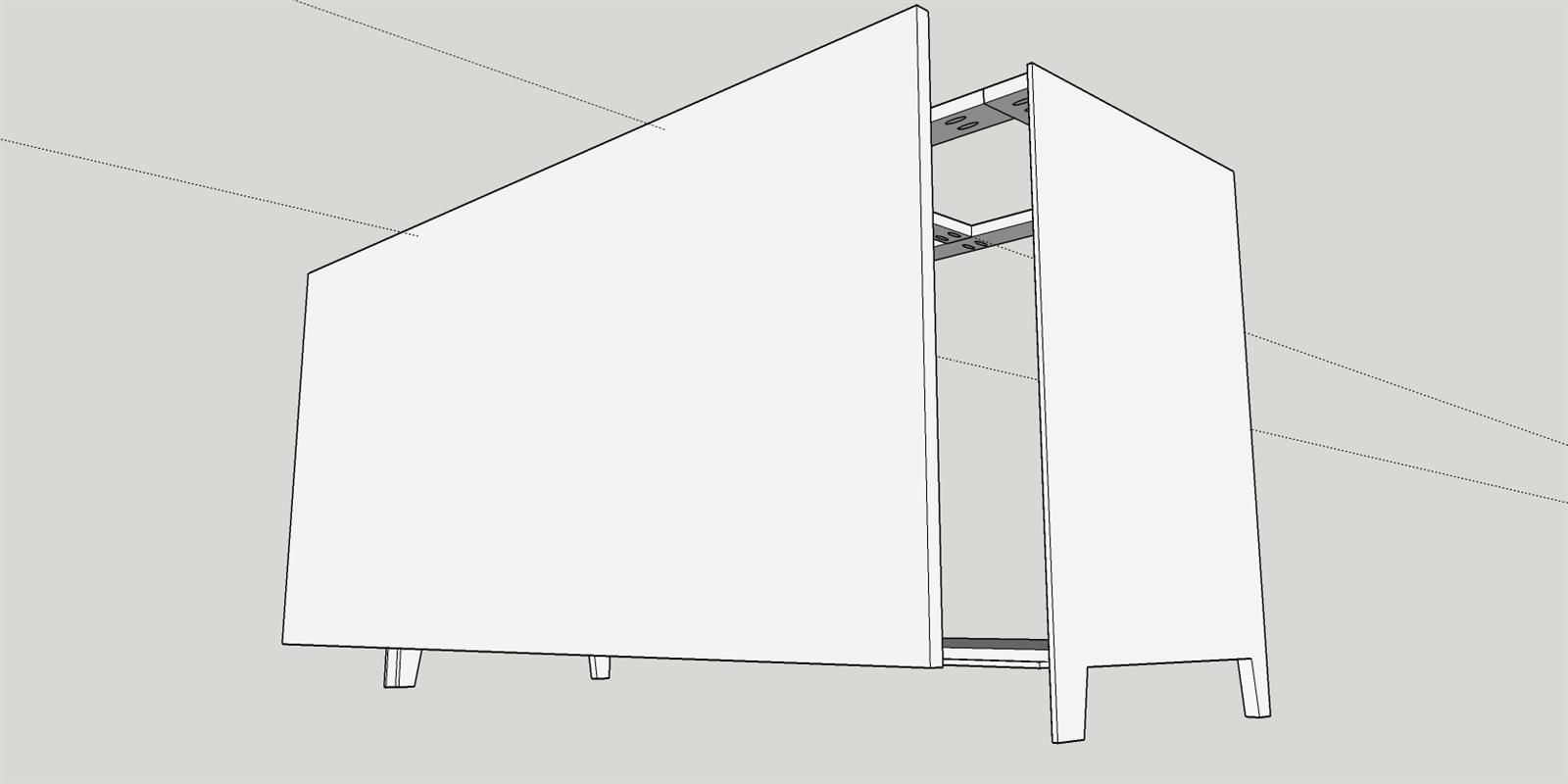

Maple Combination Dresser and Craft Cabinet

By fcbeckerWe needed a dual purpose cabinet for our guest bedroom. This dresser provides storage for guests things and my wife's fiber crafts. The maple cabinet was designed to store a sewing machine, sewing supplies and thread cones for weaving. 4 drawers and 4 sliding shelves were incorporated in the project

Directions

-

Introduction

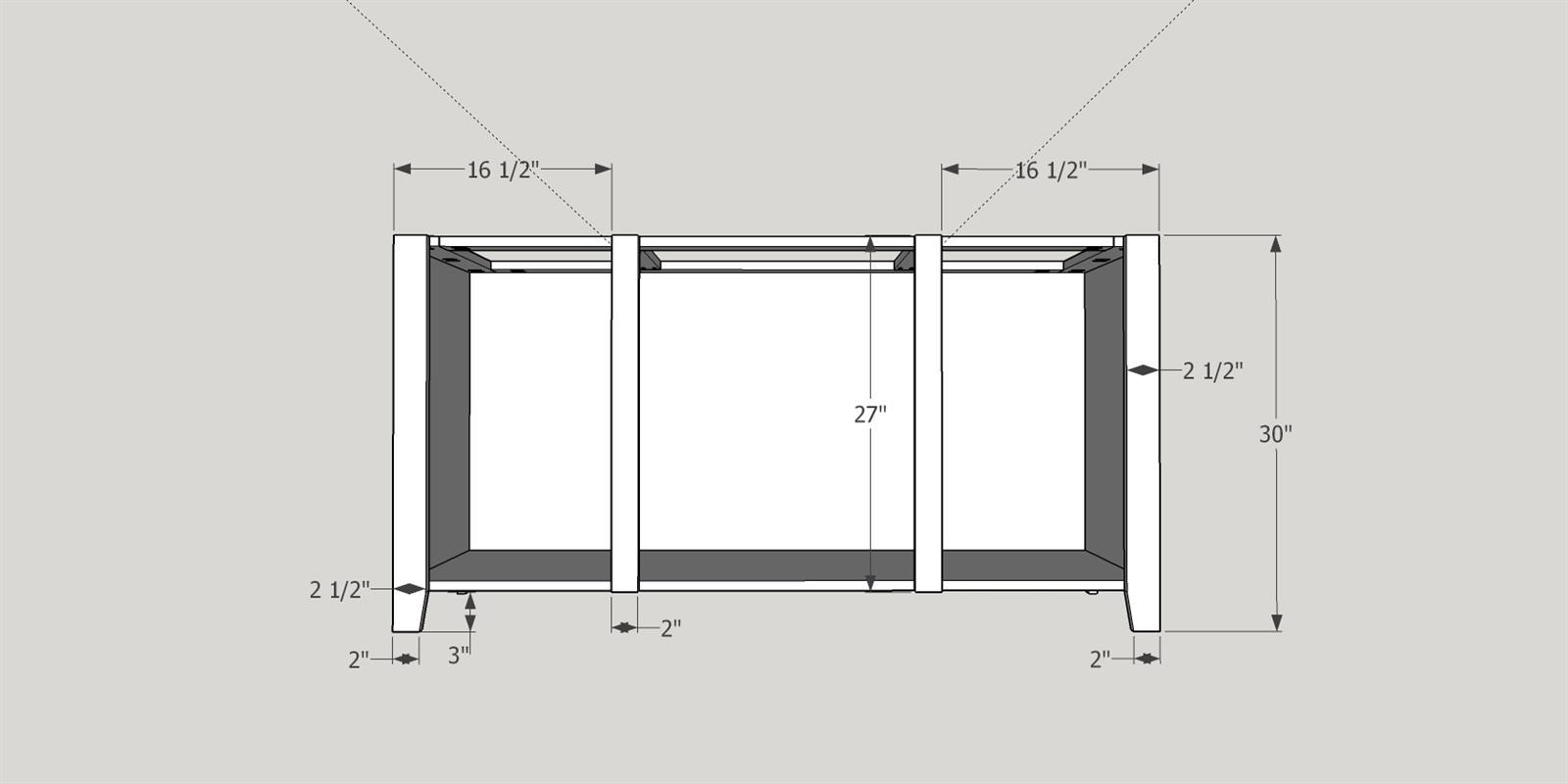

Please be sure to read through complete instructions before you begin any work on this project. Also keep in mind that plywood may be slightly thinner than its stated thickness. So some minor adjustments to plans may be required. Another good practice to use is, after the original carcass is assembled, cut to fit all additional pieces that are needed. While every effort was made to make the cut dimensions listed as accurate as possible, cutting to fit will adjust for any slight discrepancies in your assembly. I use rough boards from Albuquerque Hardwoods that I cut, flatten and plane to final dimensions. Dimensional lumber will work as well it will just be more expensive. See Popular Woodworking article linked in the Extras section.

-

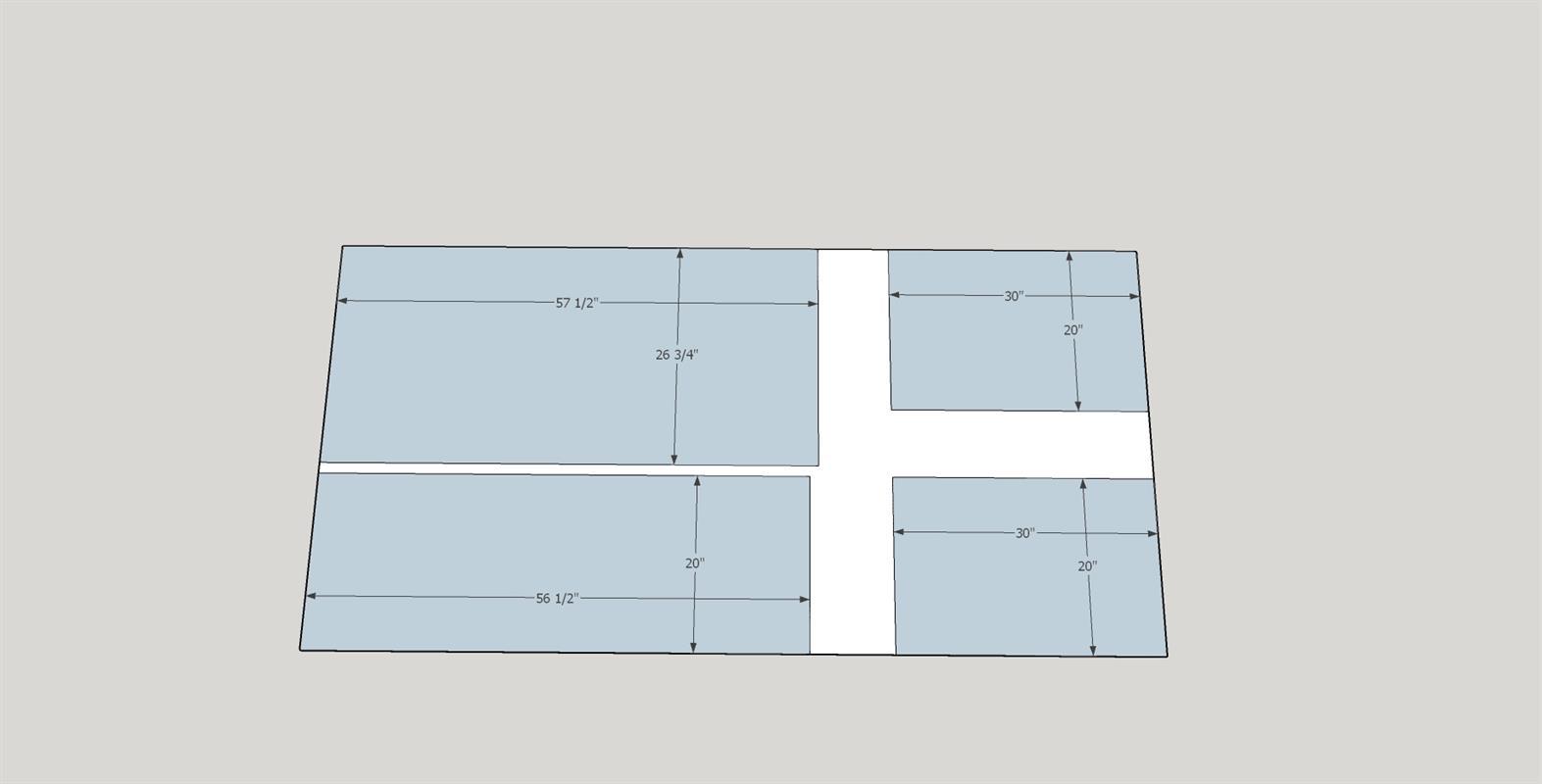

Cut 3/4" Maple Boards

Using the dimensions in the cut/parts list cut the pieces required for assembly. Please note that the top and doors will require gluing up. Two - four pieces will be used for the doors and three - four pieces for the top depending on the size of your boards. It is a good idea to label the individual boards that will make up the drawer fronts and top. It is also a good idea to go through the boards and select the parts of the boards that best match color and grain for the glue ups. Use 100 - 150 grit sandpaper to smooth the parts.

-

Cut 3/4" Maple Plywood

Cut 3/4" maple plywood to the dimensions listed in the Parts/Cut List. Smooth plywood with 150 grit sandpaper.

-

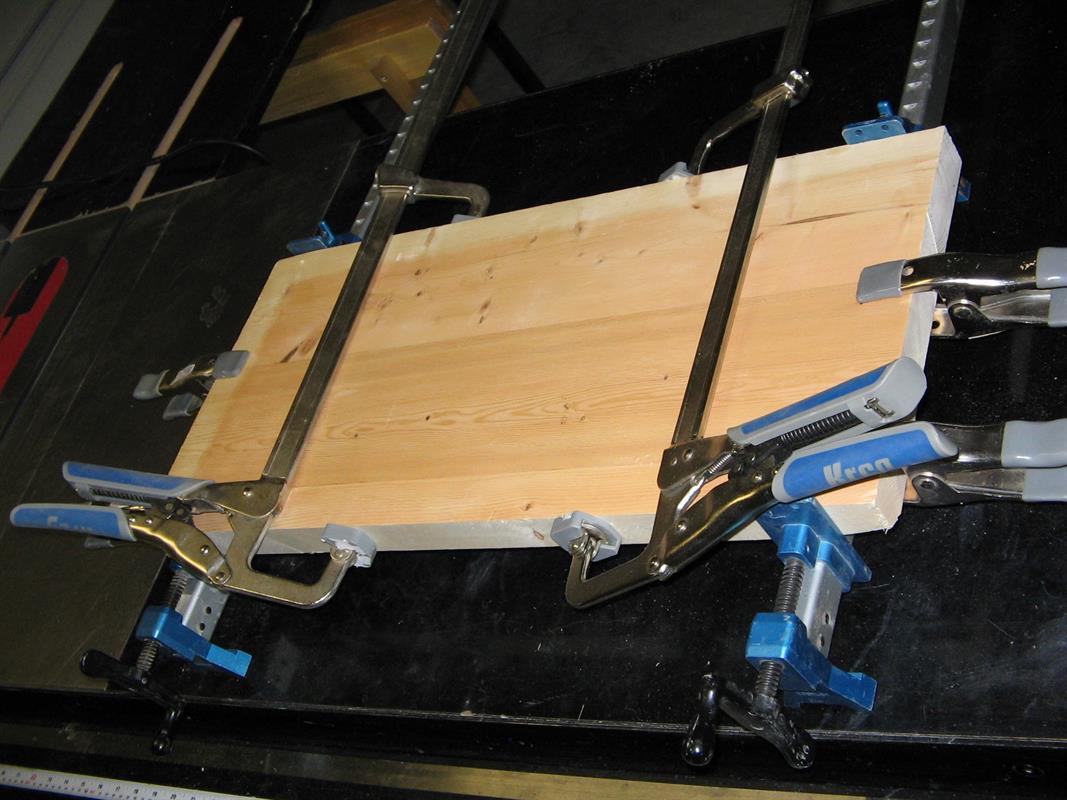

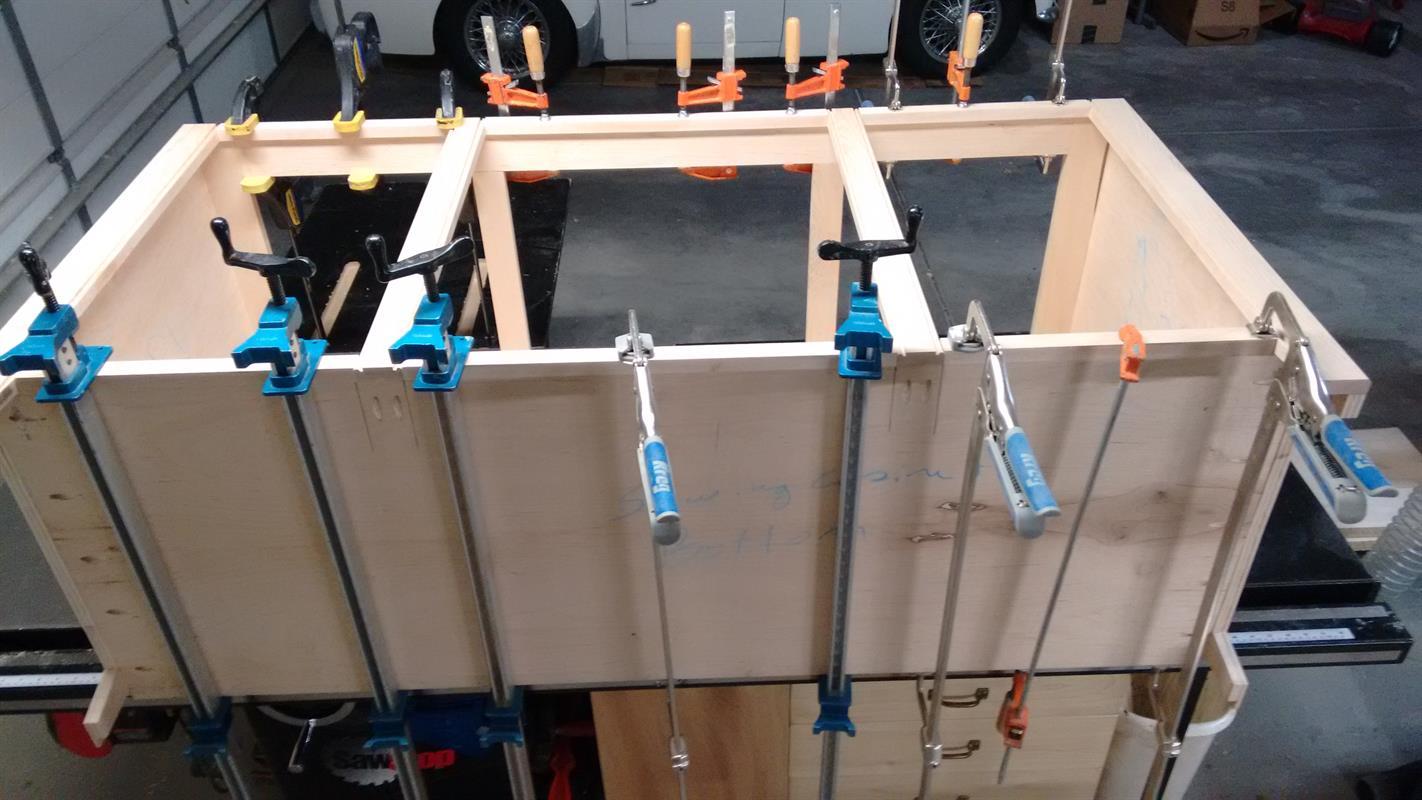

Edge Gluing

For the doors and top we edge glue the appropriate boards from step 2. If you are uncomfortable doing this I have attached one site with good information on the process. Please feel free to look at other sites. I normally use my Jet jointer to square and flatten the edges. Lay out the boards to provide the best looking grain. Use multiple clamps to bring the boards together. Make sure that the edges fit together well. Release the clamps and spread Titebond I wood glue along all of the edges to be joined. Avoid using excess glue. Realign the boards and clamp snugly. A picture of a typical clamp up follows.

-

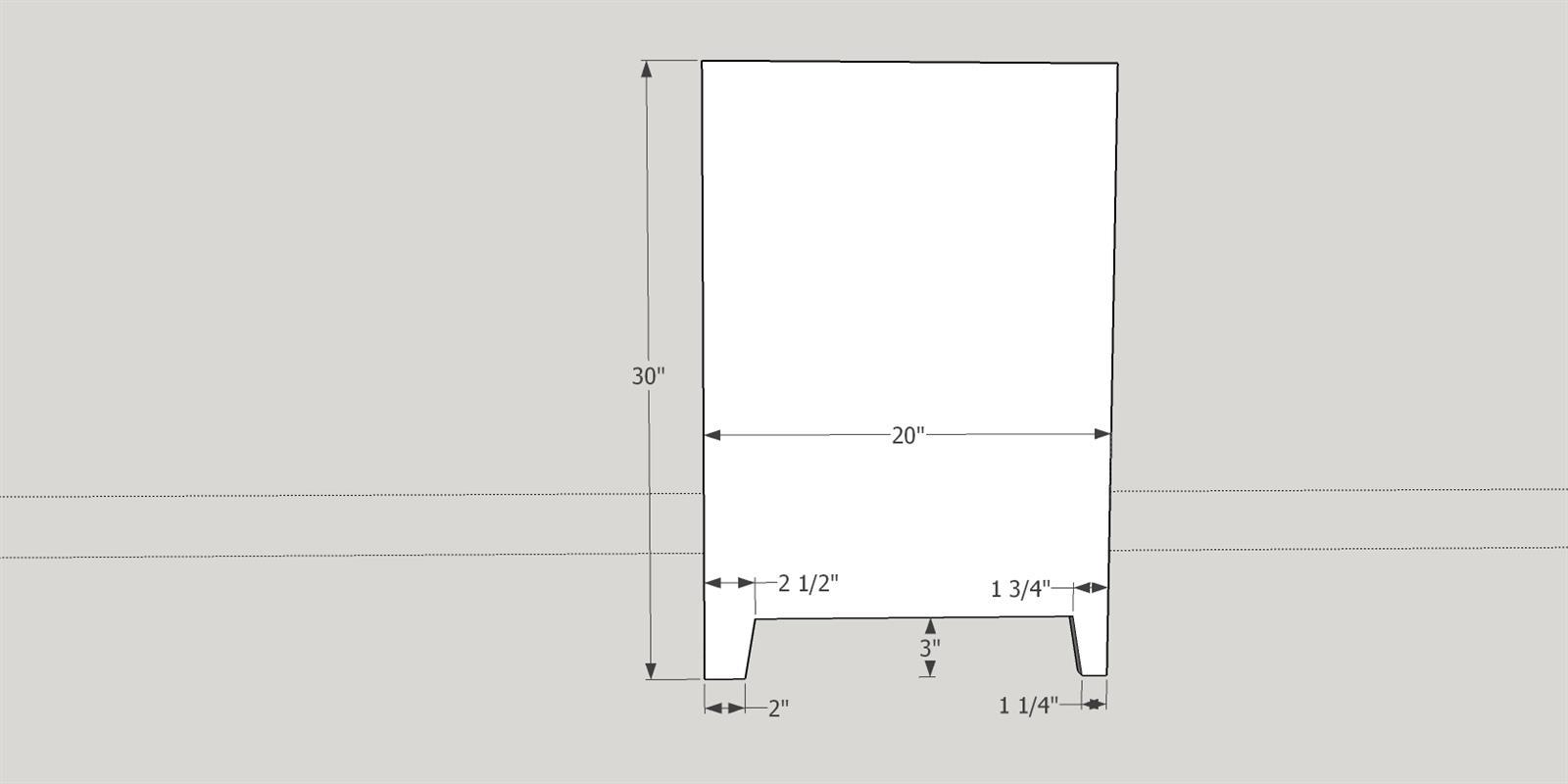

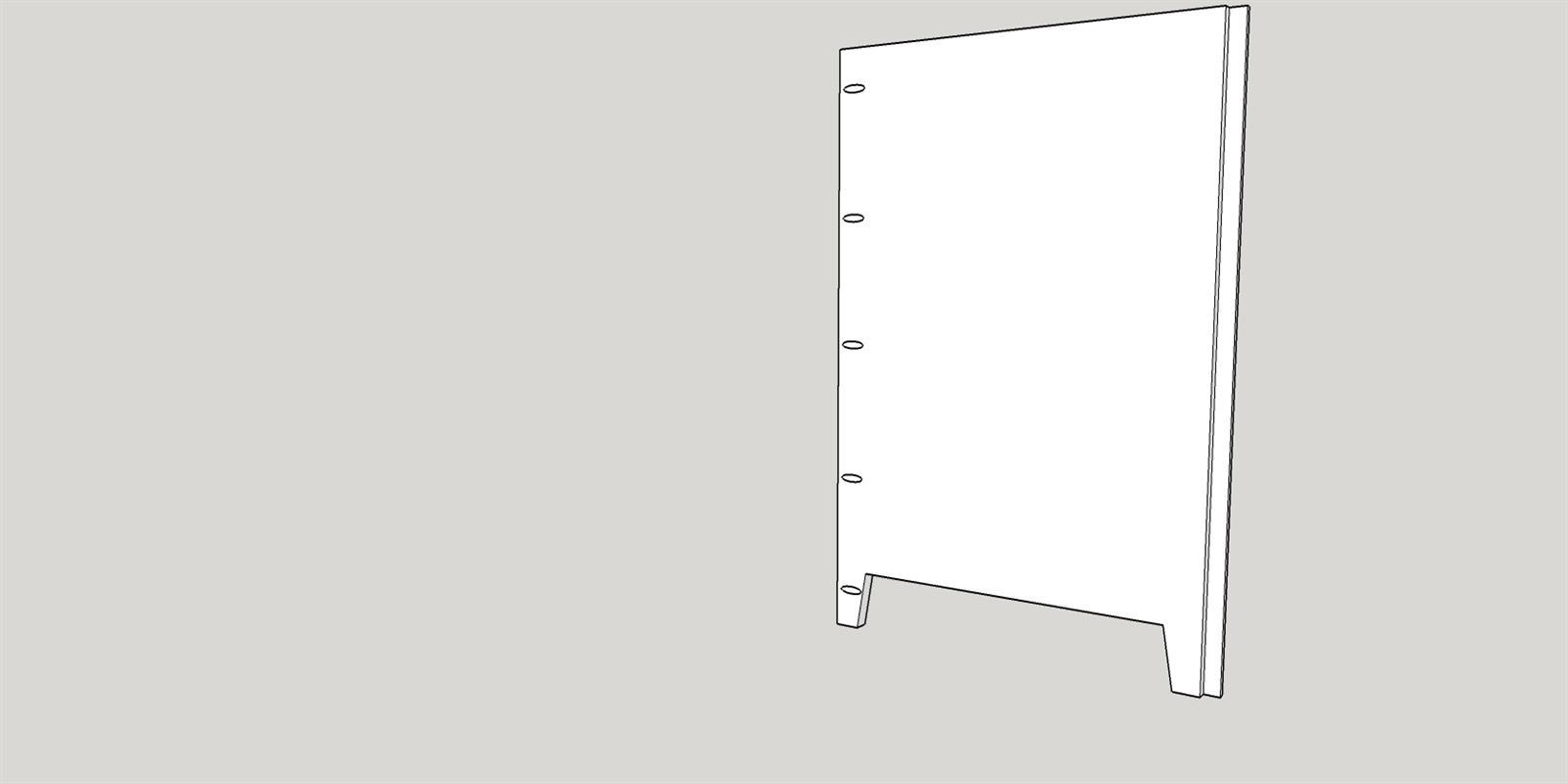

Cut Leg Openings

Using a band saw or jig saw cut the leg openings in both side pieces. Use care to get a smooth cut with no tear out. Also keep in mind that you will be cutting a left and right side...so keep the best looking side out on both.

-

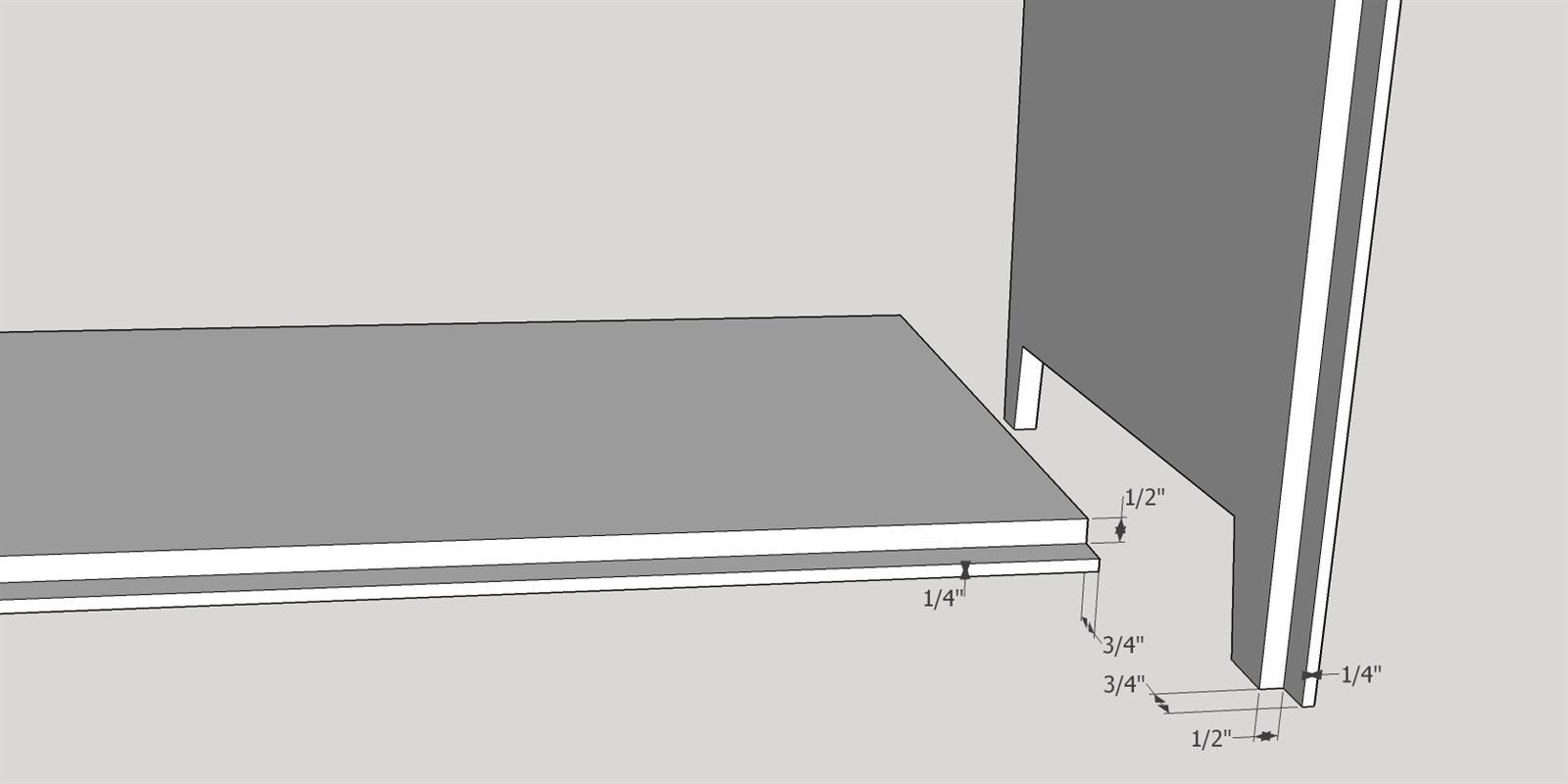

Rabbet Sides and Bottom

Use either a table saw or a router table with the appropriate bit to cut a 3/4" by 1/2" rabbet in the back inside edges of the case sides and bottom. When assembled these rabbets will hold the cabinet back. If your plywood is thinner than 3/4" you will need to adjust the rabbit to that size. (e.g. 23/32" by 1/2")

-

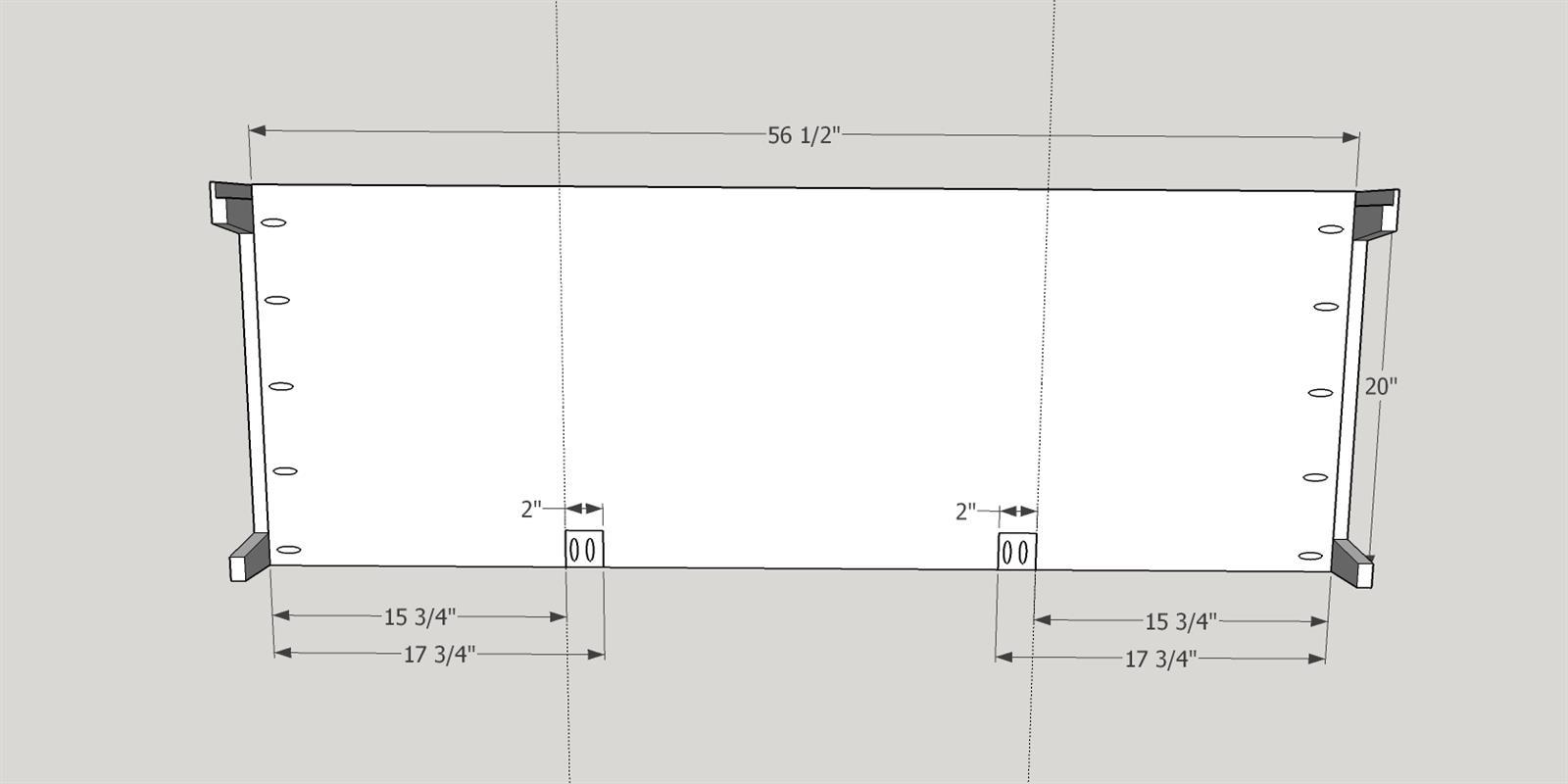

Add Pocket Holes to Bottom

Use a Kreg Pocket Hole Jig set to 3/4" to place pocket holes in the ends and front (edge without Rabbet) of the case bottom. The four holes in the front edge will hold the inner frame stiles.

-

Add Pocket Holes to Sides

Use a Kreg Pocket Hole Jig set to 3/4" to place pocket holes in the front inside edges of both sides. The holes in the front edge will hold the outer frame stiles.

-

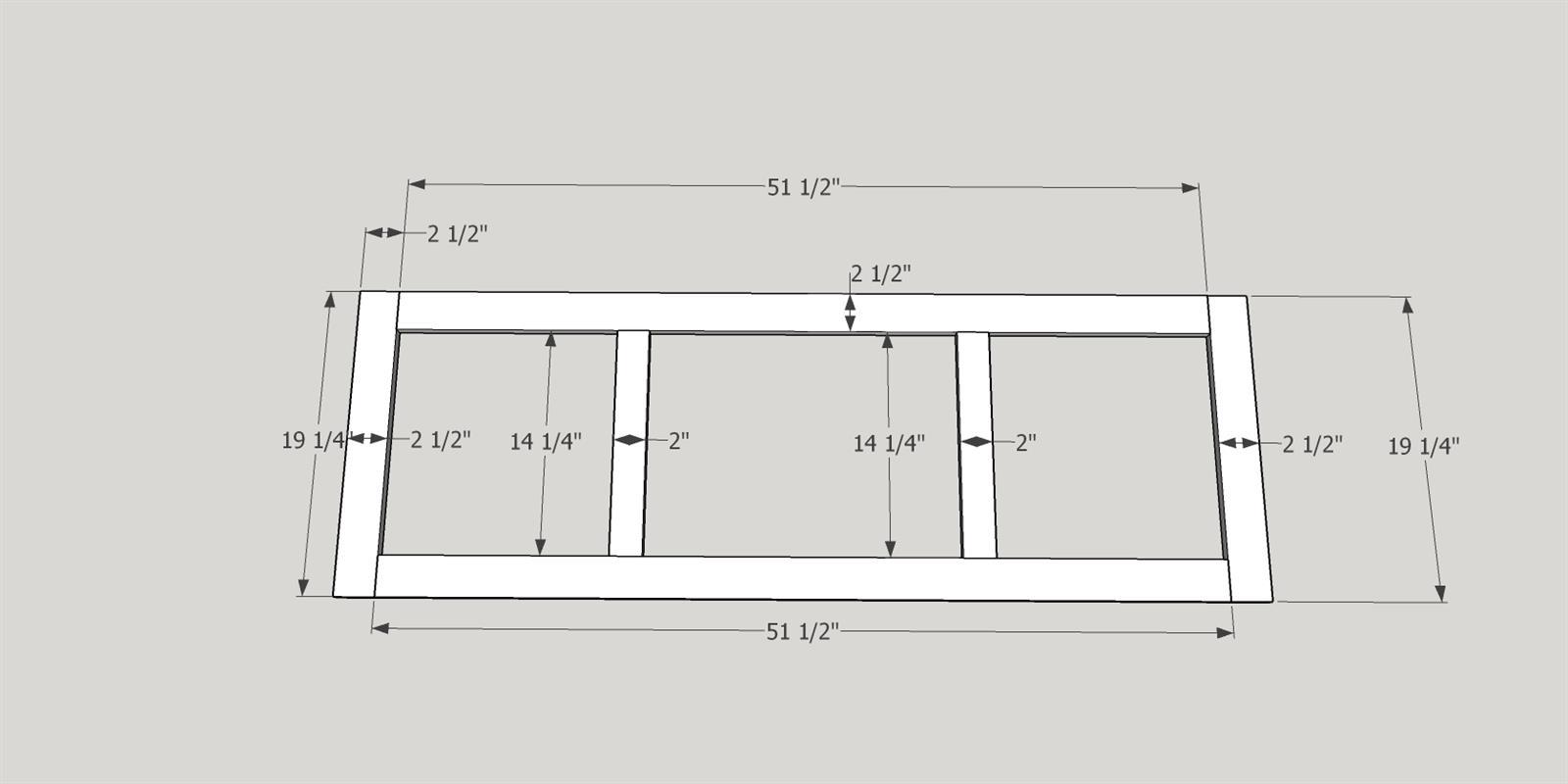

Cut the 3/4" Poplar Boards

Using the dimensions listed in the Parts/Cut List cut the six 3/4" poplar boards that will make up the top frame.

-

Add Pocket Holes to Top Frame

Use a Kreg Pocket Hole Jig set to 3/4" to place pocket holes in the top frame boards as shown in the following diagram. Use Titebond I wood glue and 1 1/4" coarse Kreg Pocket screws to assemble the frame.

-

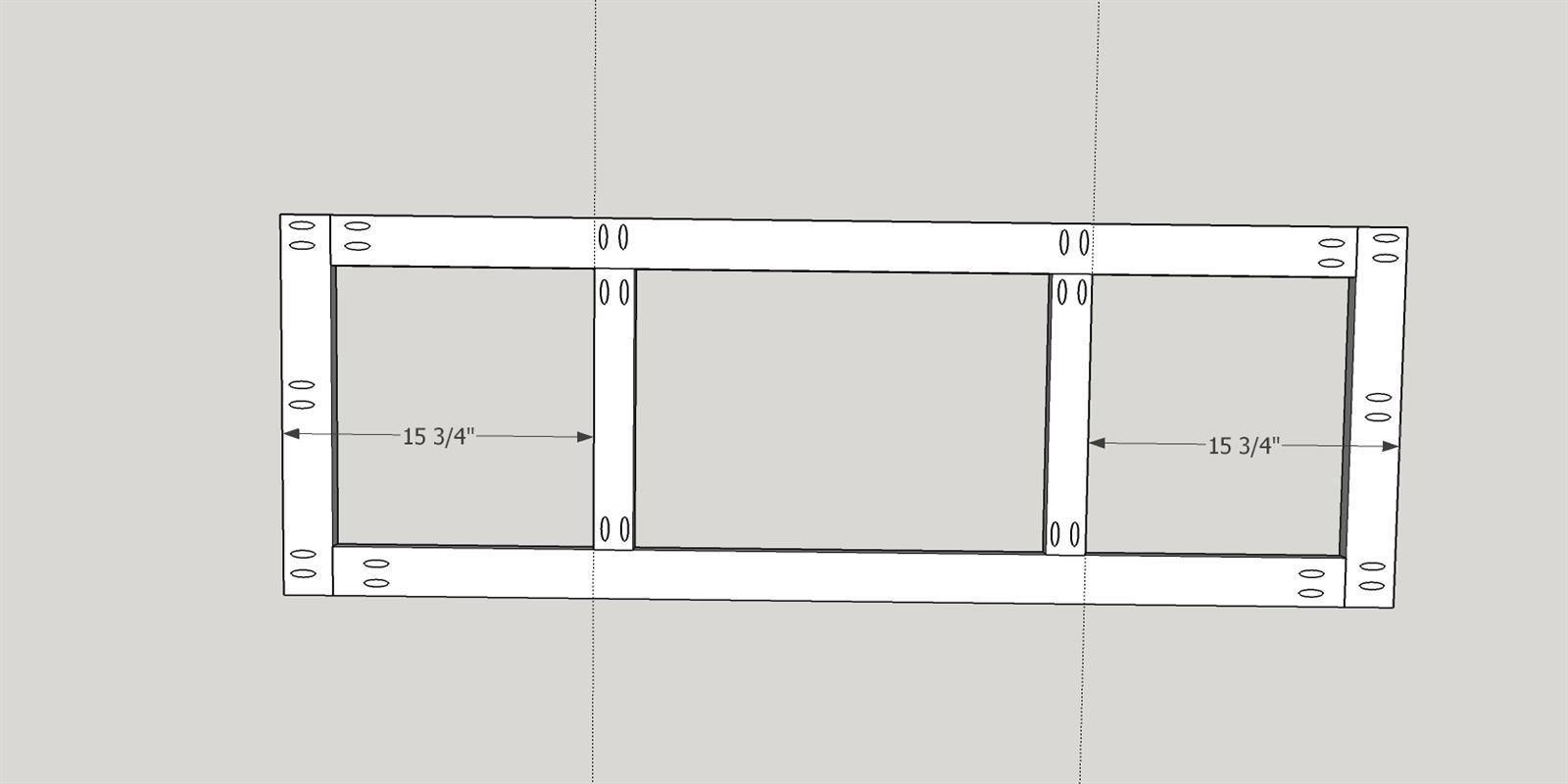

Assemble Case

Assemble sides, bottom, and top frame using Titebond wood glue and 1 1/4" coarse Kreg pocket screws. Please note...all pocket screws on the bottom should face down and all pocket screws on the sides should be inside and the top frame pocket holes should face down. Then attach the back using Titebond I wood glue and 1 1/4" brad or finishing nails.

-

Front Inner and Outer Stiles

Select the front inner and outer stiles that were cut in step 2. Cut the legs on the outer front stiles using either a band saw or a jig saw. Use Titebond I wood glue and Kreg fine 1 1/4" pocket screws to attach the outer and inner frame stiles to the cabinet case.

-

Front Rails

Select the front rails cut in step 2. Use Titebond I wood glue and use either brad nails or clamps to hold in place until glue dries.

-

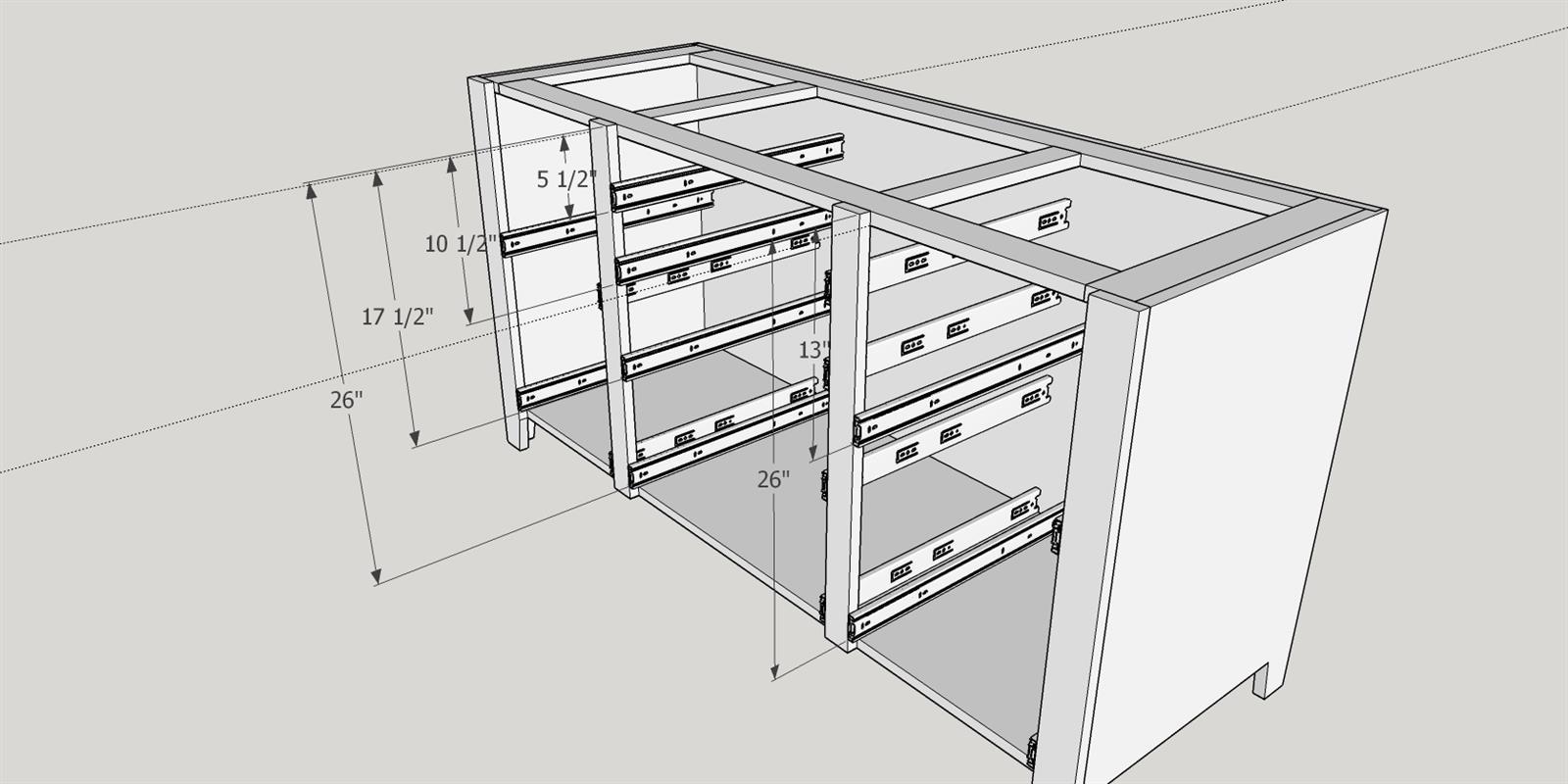

Drawer and Shelf Slides

Follow the manufacturers directions and attach the four sets of drawer and the four sets of shelf slides. The shelves can be placed at the most useful spacing for your needs. My shelf spacing was based on the size of the sewing machine we wanted to store in the cabinet.

-

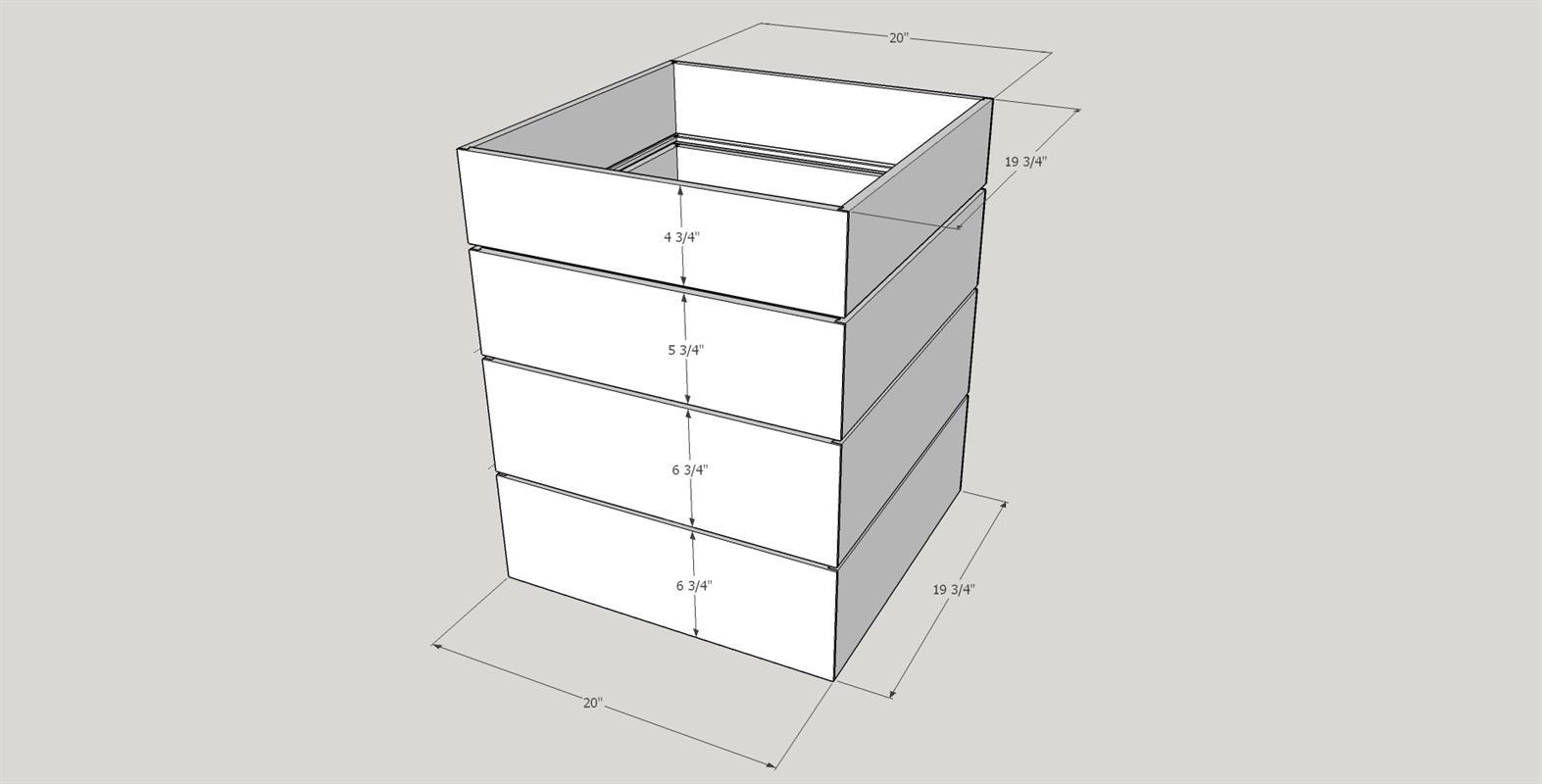

Cut Drawer Boxes

Cut the eight drawer sides and eight drawer fronts/backs from 1/2" poplar (you can use 1/2" plywood but watch the thickness as it might be slightly less than 1/2"). Cut the four drawer bottoms from 1/4" plywood. Please note that my sizes are approximate and will vary depending on how you construct the box corners. I use a Freud (99-240) Drawer lock bit on my Kreg router table to cut all of the corners. I then use my table saw to cut a 1/4" deep X 1/4" wide dado in all sides and fronts/backs. This dado should be 1/4 inch up from the bottom of each board. Once you have completed all of the operations prep all surfaces with 150 grit sandpaper.

-

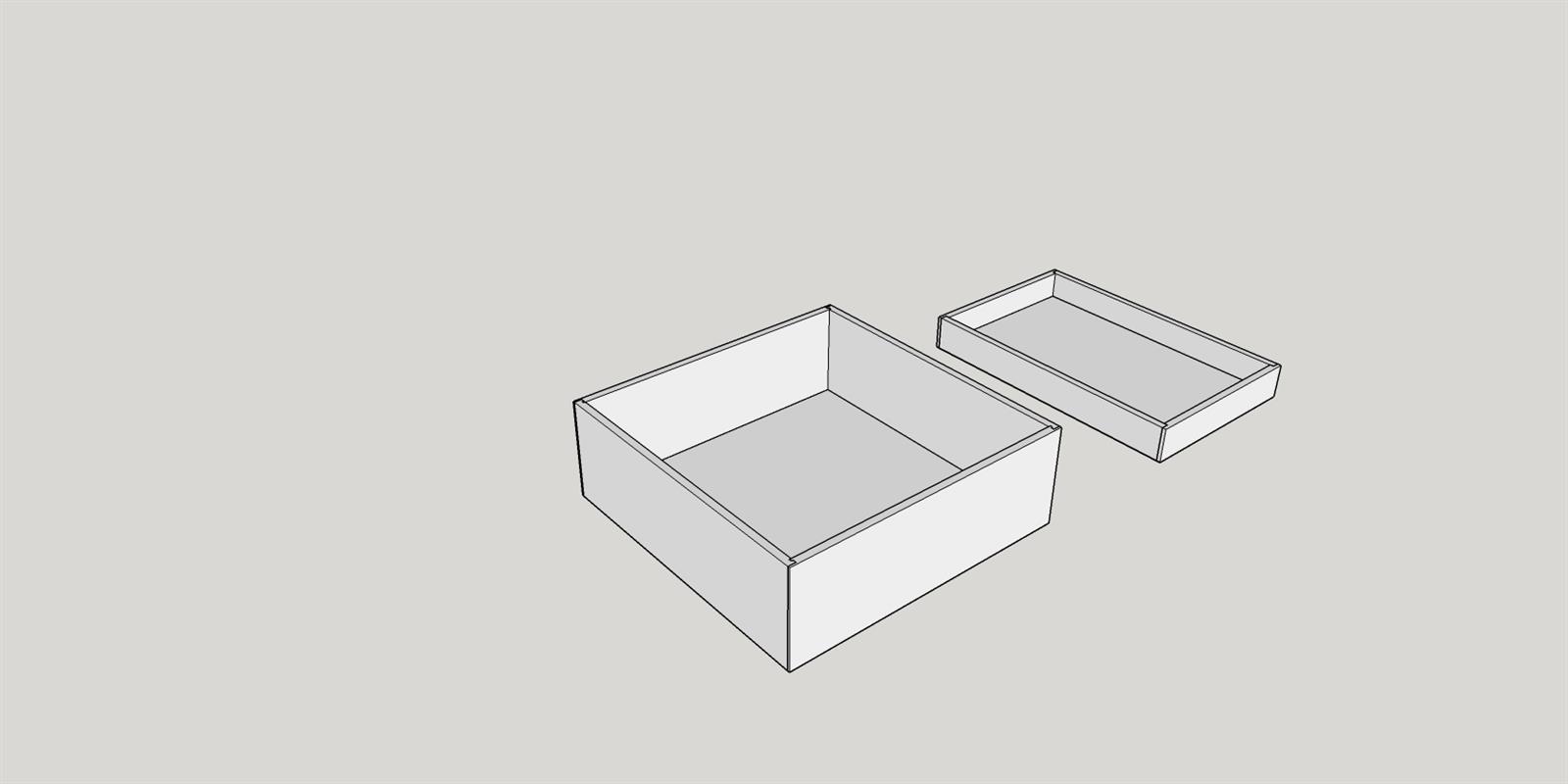

Cut Sliding Shelves

Cut the eight shelf sides and eight shelf fronts/backs from 1/2" poplar (you can use 1/2" plywood but watch the thickness as it might be slightly less than 1/2"). Cut the four shelf bottoms from 1/2" plywood. Please note that my sizes are approximate and will vary depending on how you construct the box corners. I use a Freud (99-240) Drawer lock bit on my Kreg router table to cut all of the corners. I then use my table saw to cut a 1/2" deep X 1/2" inch wide dado in all sides and fronts/backs. This dado should be 1/4 inch up from the bottom of each board. Once you have completed all of the operations prep all surfaces with 150 grit sandpaper.

-

Assemble Drawer Boxes and Shelves

Assemble drawers using the two matched sides, a back, a front and a bottom. I use wood glue at each corner joint and on the edges of the plywood bottom. You can either clamp until the drawers are dry or use pin nails in each corner. Repeat this process three more times until all drawer boxes are complete and four more times until all Sliding shelves are complete. Smooth with 150 - 220 grit sandpaper and seal with three coats of Minwax Polycrylic Satin Finish.

-

Door Assemblies

Cut the two doors to final size. I used a half round router bit to ease over the front edges of the doors. Smooth with sandpaper 100 - 220 grit. Following the manufacturers instructions attach the hinges of your choice (I used 105 Degrees Compact Cabinet Hinge, 1/2" Overlay from Amazon) to the doors. Attach the doors to the face frame.

-

Attach Drawer Boxes and Fronts

Attach the drawer boxes and fronts to the drawer slides. Start at the bottom, attach the box first and then attach the drawer front to its box. Repeat this process three additional times to complete the drawer stack. You may have to cut a small amount off of the top or bottom of the drawer fronts to provide proper spacing. I use dimes as spacers between the drawer fronts. Smooth the drawer fronts with 100 - 220 grit sandpaper.

-

Top Assembly

Cut top assembly to final dimensions and round over the top edges. Smooth top with 100 - 220 grit sandpaper. The top is held in place by four Kreg 1 1/4" fine pocket screws that have flat washers added. (see picture) Drill four 1/4" holes in the top cabinet frame. Place the top on the cabinet. Center the top, approximately 1" overhang on both sides and 1 1/2" at the front. Insert the screws from the bottom side of the top frame. The screws should be drawn snug but not over tight. This should hold the top in place but allow for any expansion or contraction of the top.

-

Apply Finish and Hardware

Now that the build is complete use 220 sandpaper to do a once over on all surfaces in preparation for the finish. Clean well to remove all dust. (I use compressed air and clean dry rags) I gave the cabinet 2 coats of boiled linseed oil and allowed them to dry for 7 days. Then I gave it three coats of Minwax Tung Oil following manufacturers instructions. After the finish has dried add door/drawer pulls.