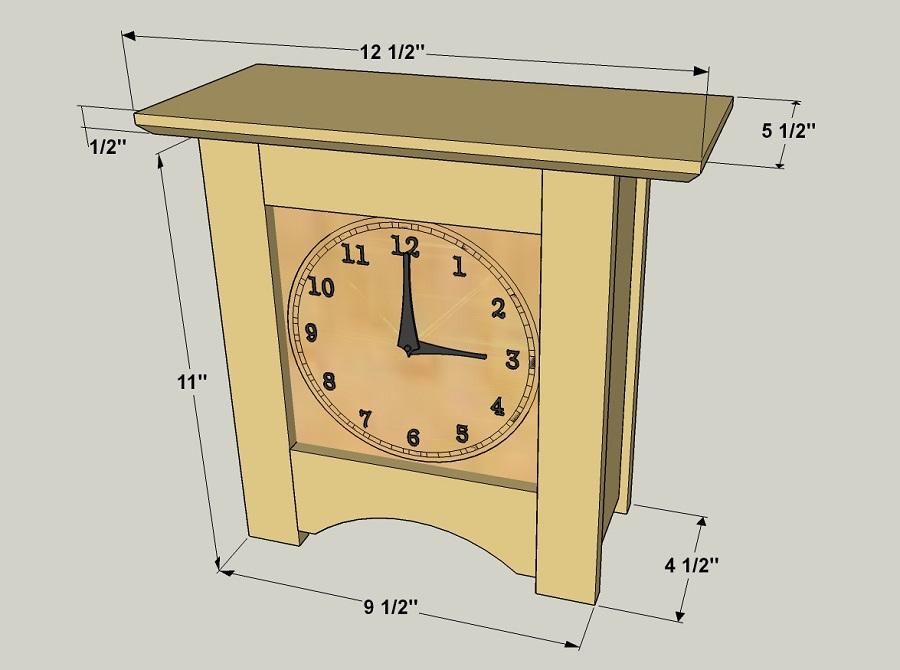

Mantel Clock with Free Printable Dial

By Kreg ToolKeep time in style and show off your skills by building this timeless classic. This mantel clock is surprisingly simple to build from off-the-shelf 1/2" and 3/4" boards, and an inexpensive clock movement. To make the project even easier, we've included a free printable dial (see Extras at the end of the plan).

Directions

-

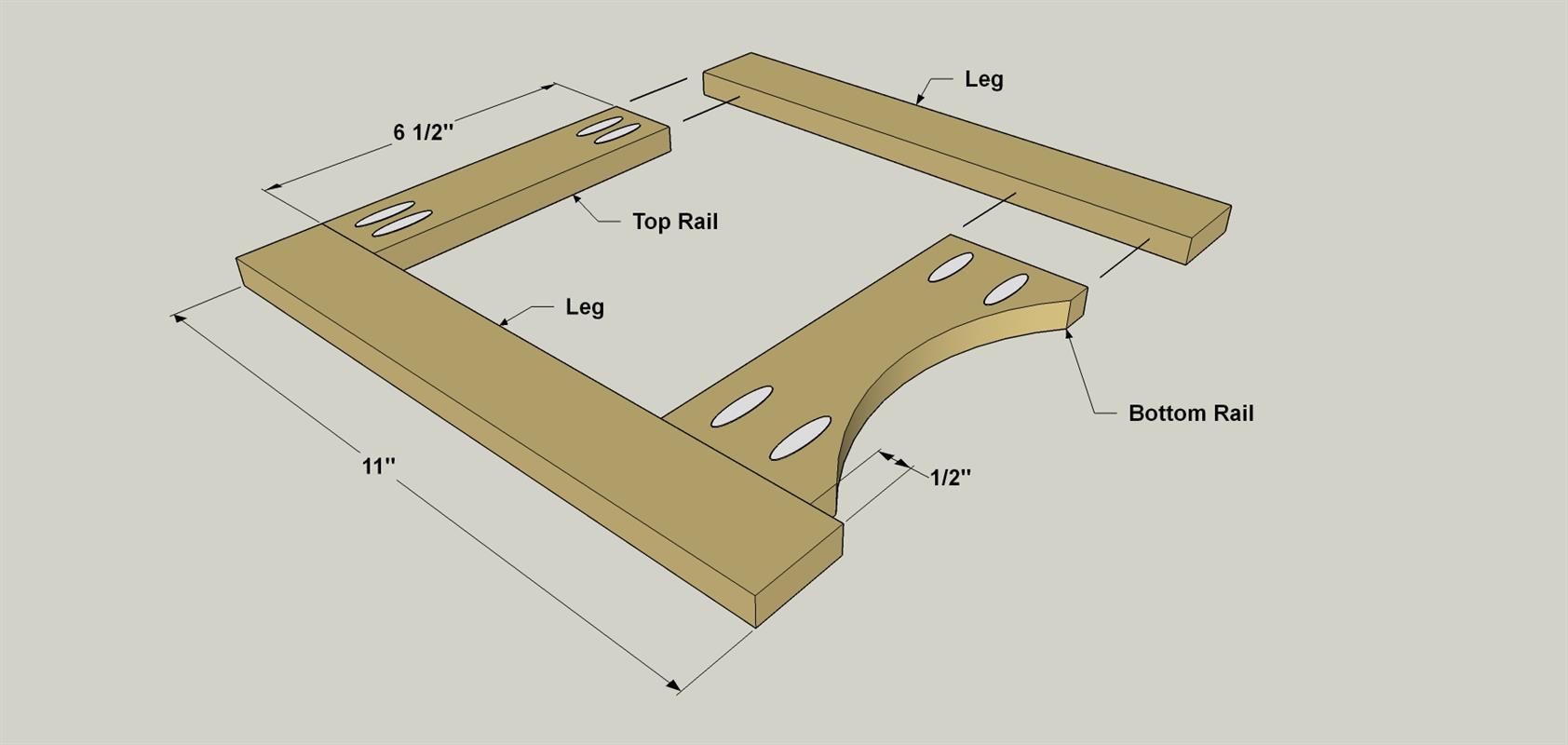

Make the Legs and Rail Parts

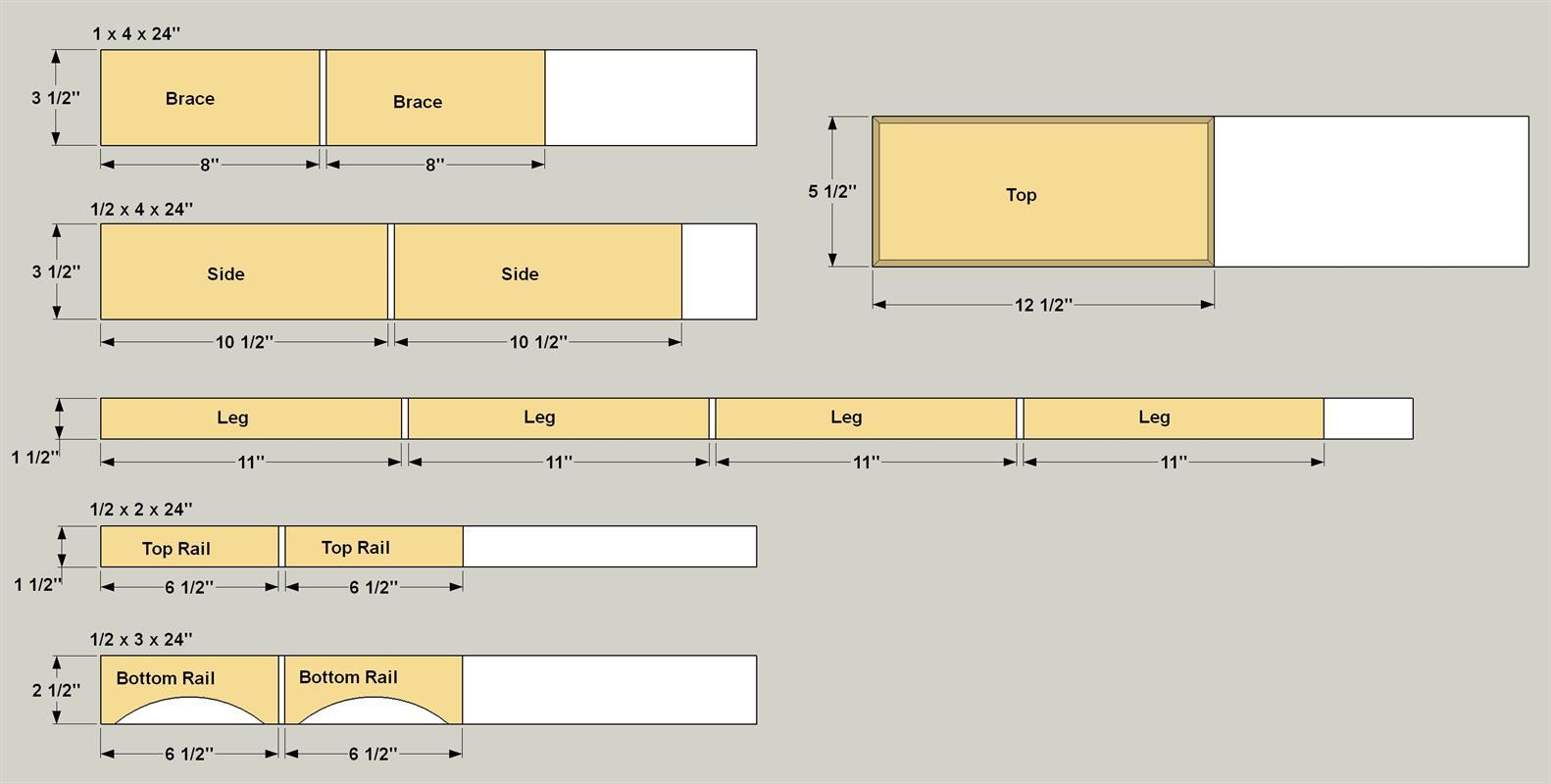

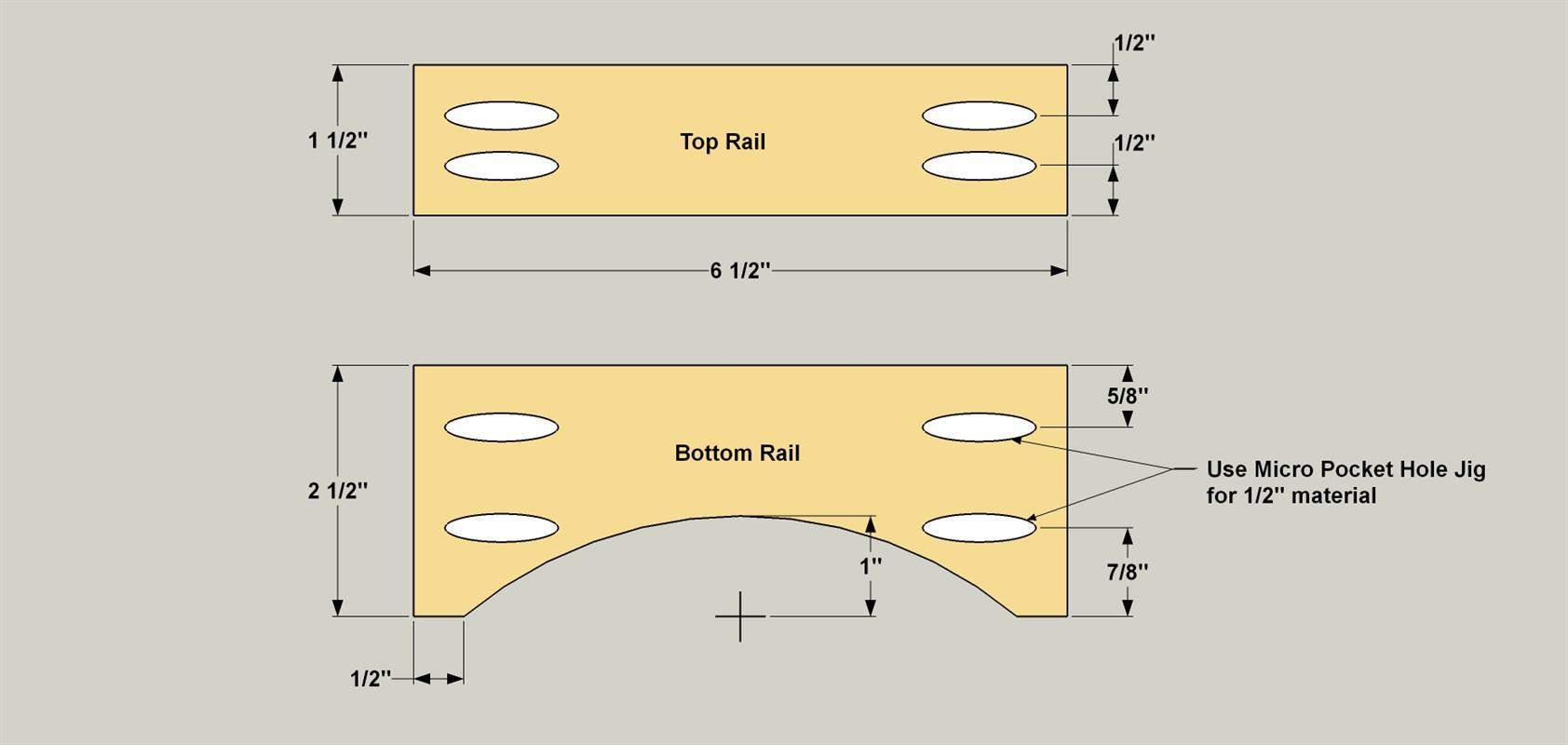

Cut four Legs and two Top Rails to length from 1/2" x 2 oak, as shown in the cutting diagram. Cut two Bottom Rails to length from 1/2" x 3 oak. Mark out the arch on one of the Bottom Rails, and then cut it with a Jigsaw. Sand the cut edge smooth, and then use this Rail as a pattern for the second one, and repeat the process. Now you can drill pocket holes. We used a Kreg Micro-Pocket™ drill guide for this project. It creates a smaller hole than a standard Kreg Jig, making it perfect for 1/2" material. If you don’t have the Micro-Pocket ™ guide, a standard Kreg Jig Drill Guide will work. With the jig set up for 1/2"-thick material, drill pocket holes in the ends of the Top and Bottom Rails as shown. Sand the parts smooth.

-

Build a Pair of Frames

Assemble two Legs, one Top Rail and one Bottom Rail with glue and 1" fine-thread pan-head pocket-hole screws to create a frame assembly. Repeat the process for the second frame. Sand faces of the frames as needed to make sure all of the joints are flush.

-

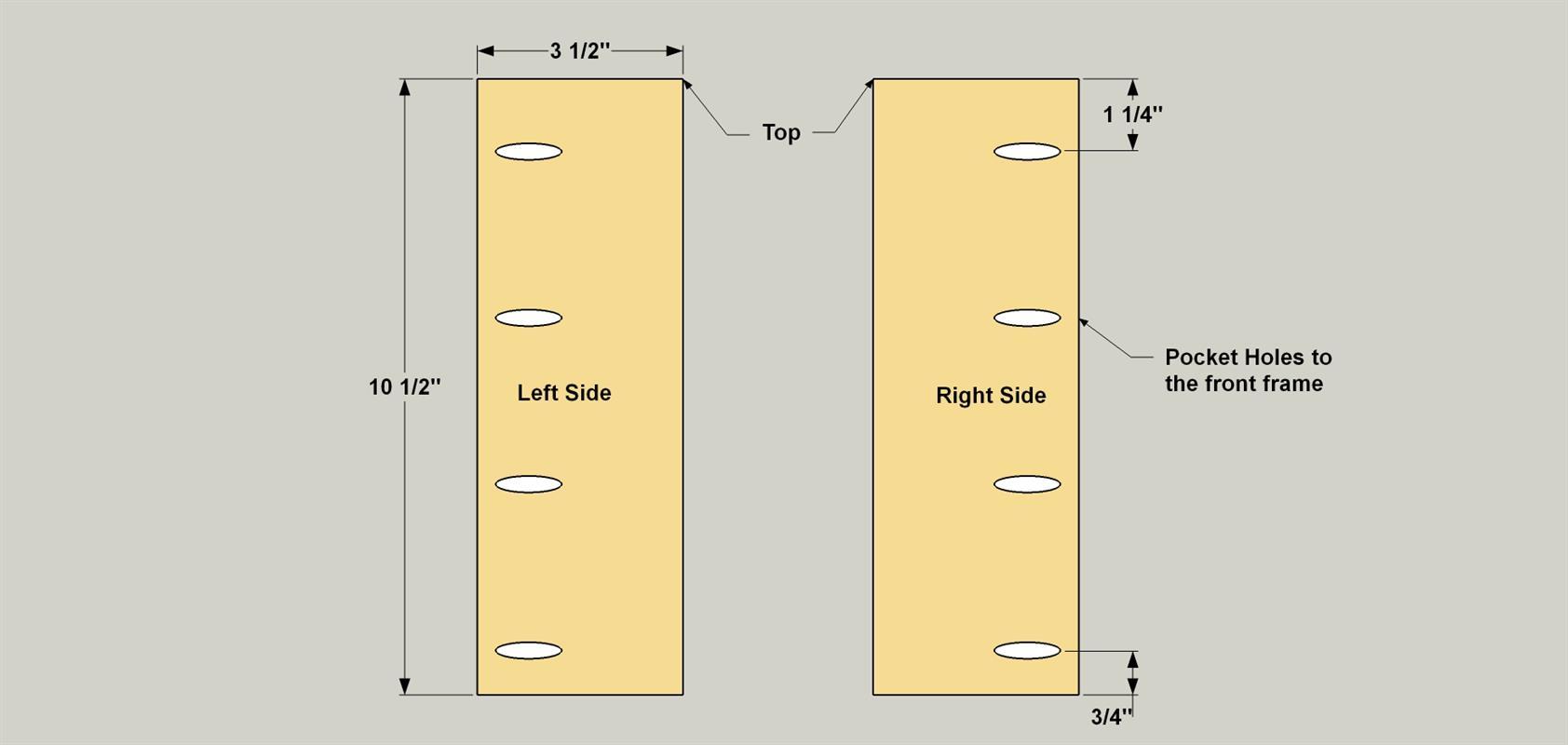

Make the Sides

Cut two sides to length from a 1/2" x 4 oak, as shown in the cutting diagram. With your jig set for 1/2"-thick material, drill pocket holes where shown. Note the pocket holes are oriented so there is a left Side and a right Side. Sand the parts smooth.

-

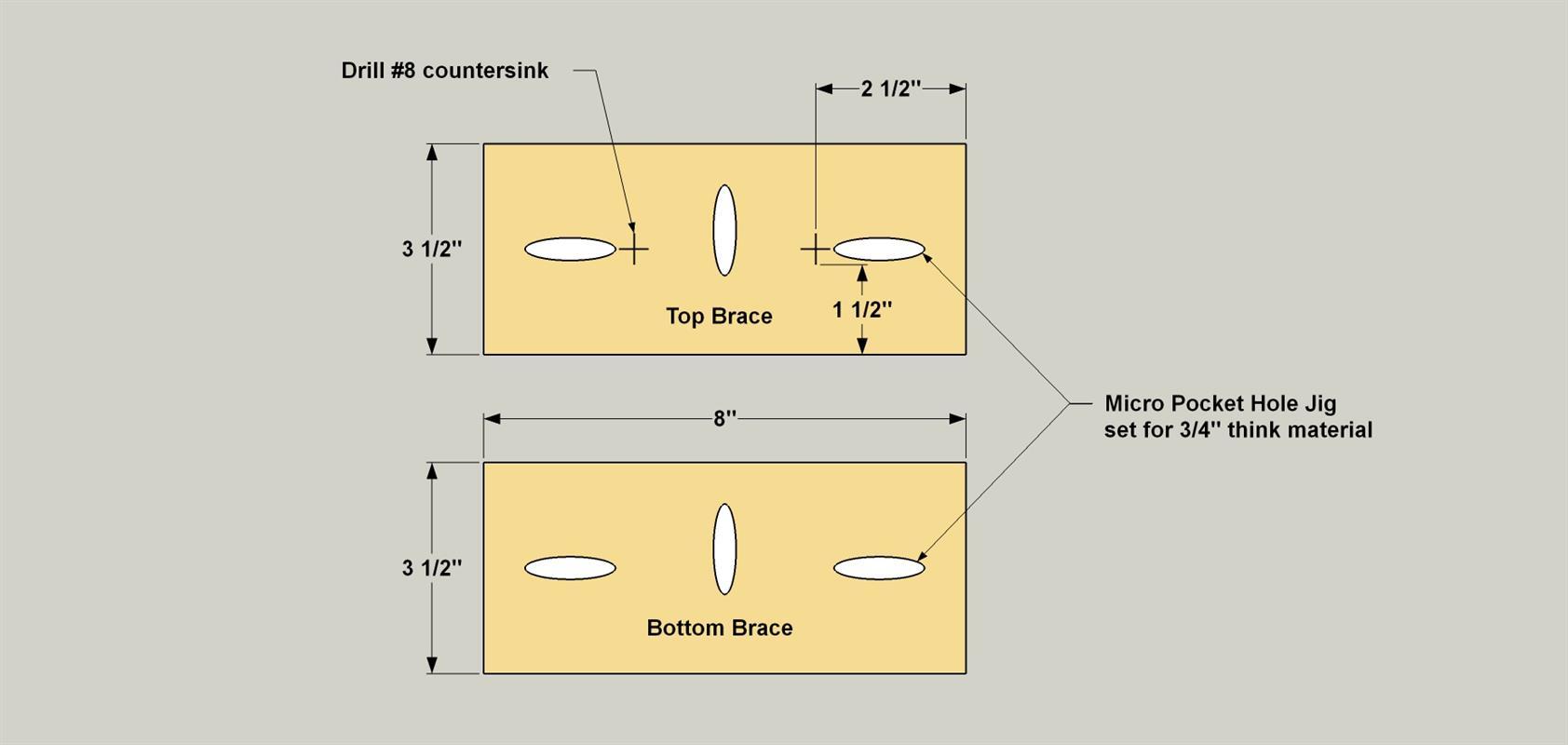

Make the Braces

Cut two Braces from 1x4 oak, as shown in the cutting diagram. Drill pocket holes at the locations shown. On the Top Brace, drill two pilot holes on the same side as the pocket holes. These will be for attaching the Top of the Clock to the body on a later step. Also drill two pilot holes, as shown, in just one Brace. This one will be positioned at the top during assembly, and the holes will be used for screws that attach the Top later. Sand the Braces smooth.

-

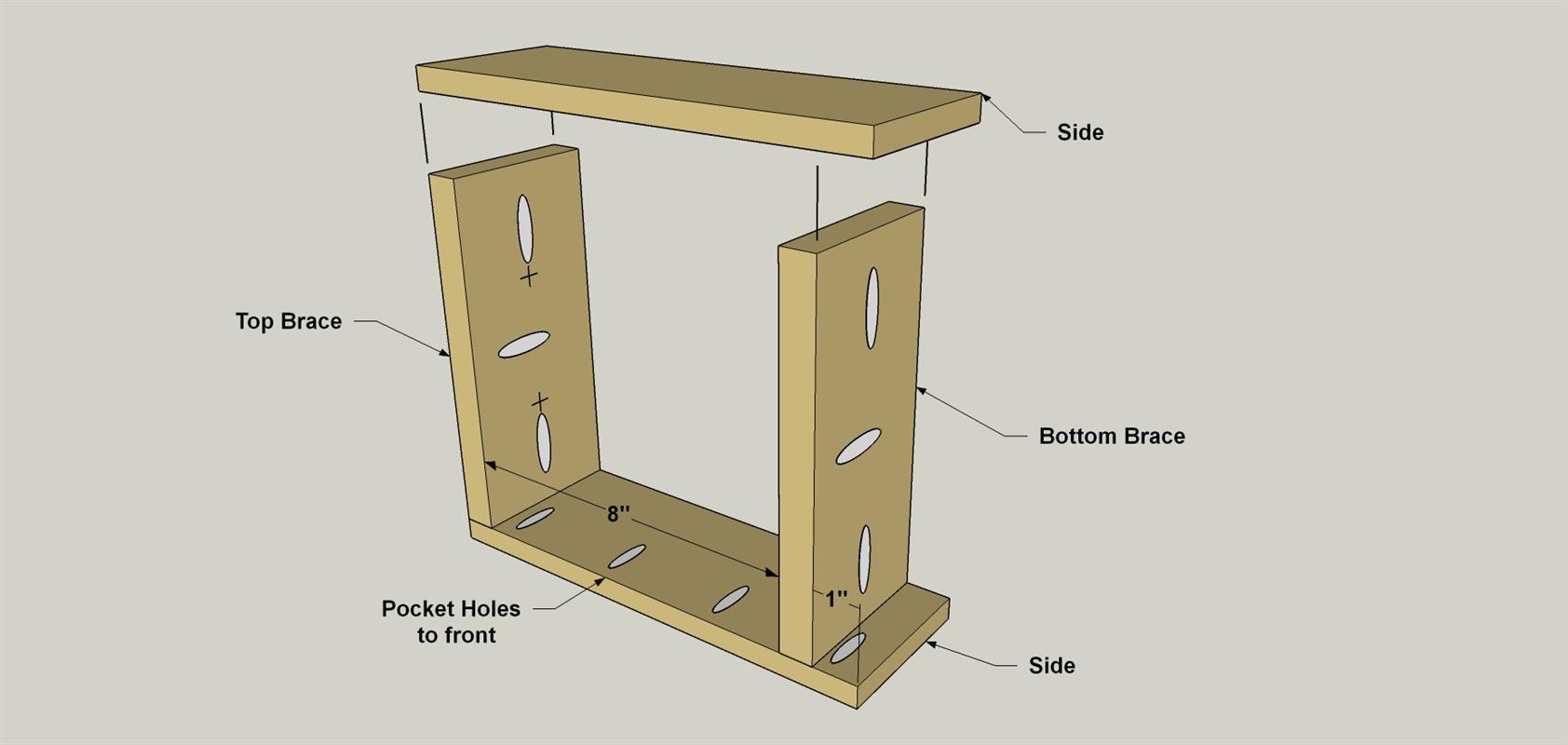

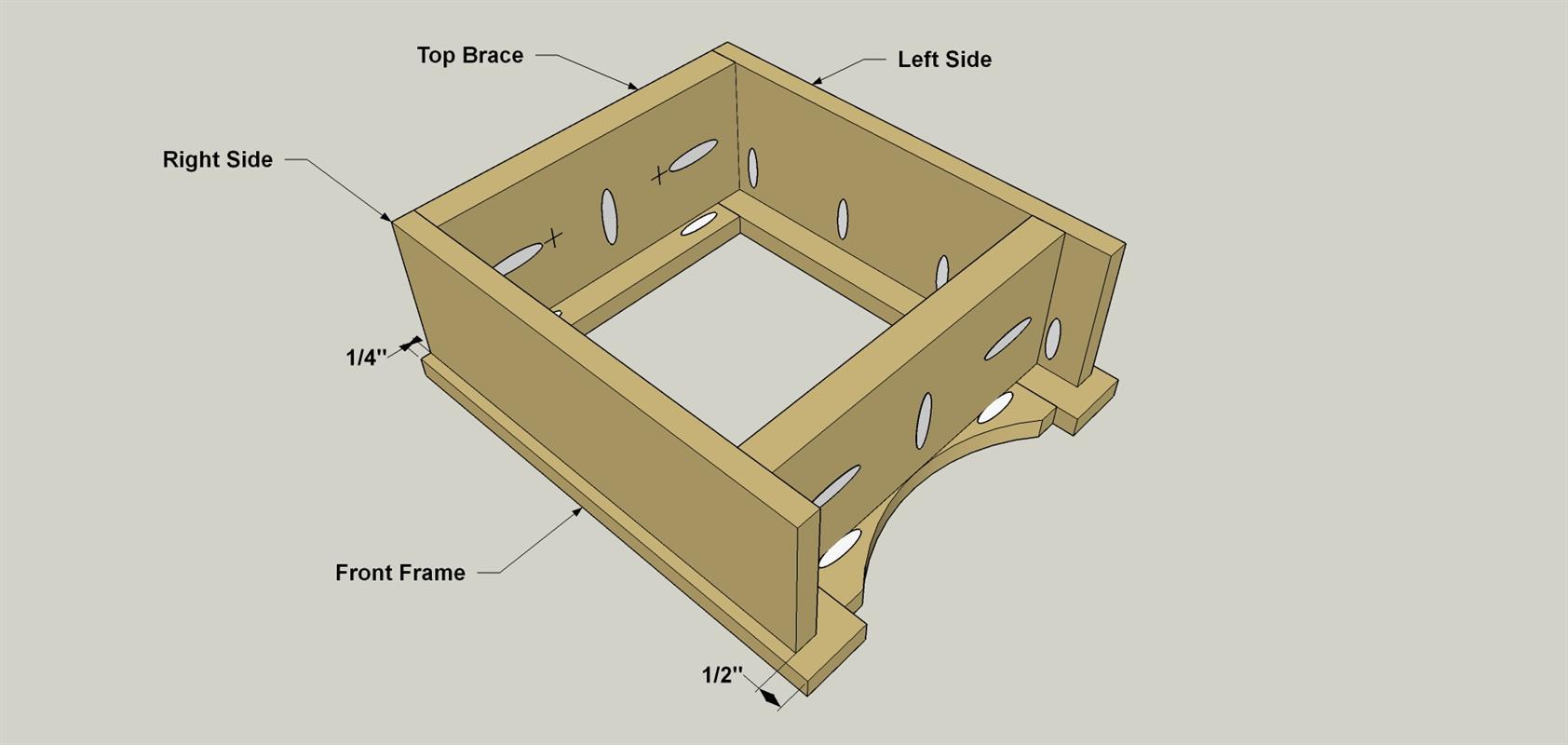

Connect the Sides to the Braces

Now you can position the Top Brace between the sides, as shown. Make sure the center pocket hole on the Top Brace faces the same direction as the pocket holes in the Sides. Attach the Top Brace to this Side using glue and 1" fine-thread pan-head pocket-hole screws. Secure the Bottom Brace in the same manner at the location shown. Then add the second Side, making sure, once again, that the pocket holes are oriented in the correct direction. Because the space is tight, you won’t be able to fit a standard drill and pocket-hole driver bit in place. A right-angle attachment like the Kreg 90° Pocket-Hole Driver, though, solves the problem easily, as shown in the tip.

-

Attach the Body to the Front Frame

Lay one frame assembly flat on a work surface with the pocket holes facing up. Place the clock body on the frame so the pocket holes in the Sides and Braces the Sides face to the Frame. Orient the body to the frame as shown, so that it sits flush with the upper end of the frame, and there are equal overhangs along the Sides. Attach the clock body to the frame assembly using glue and 1" fine-thread pan-head pocket-hole screws.

-

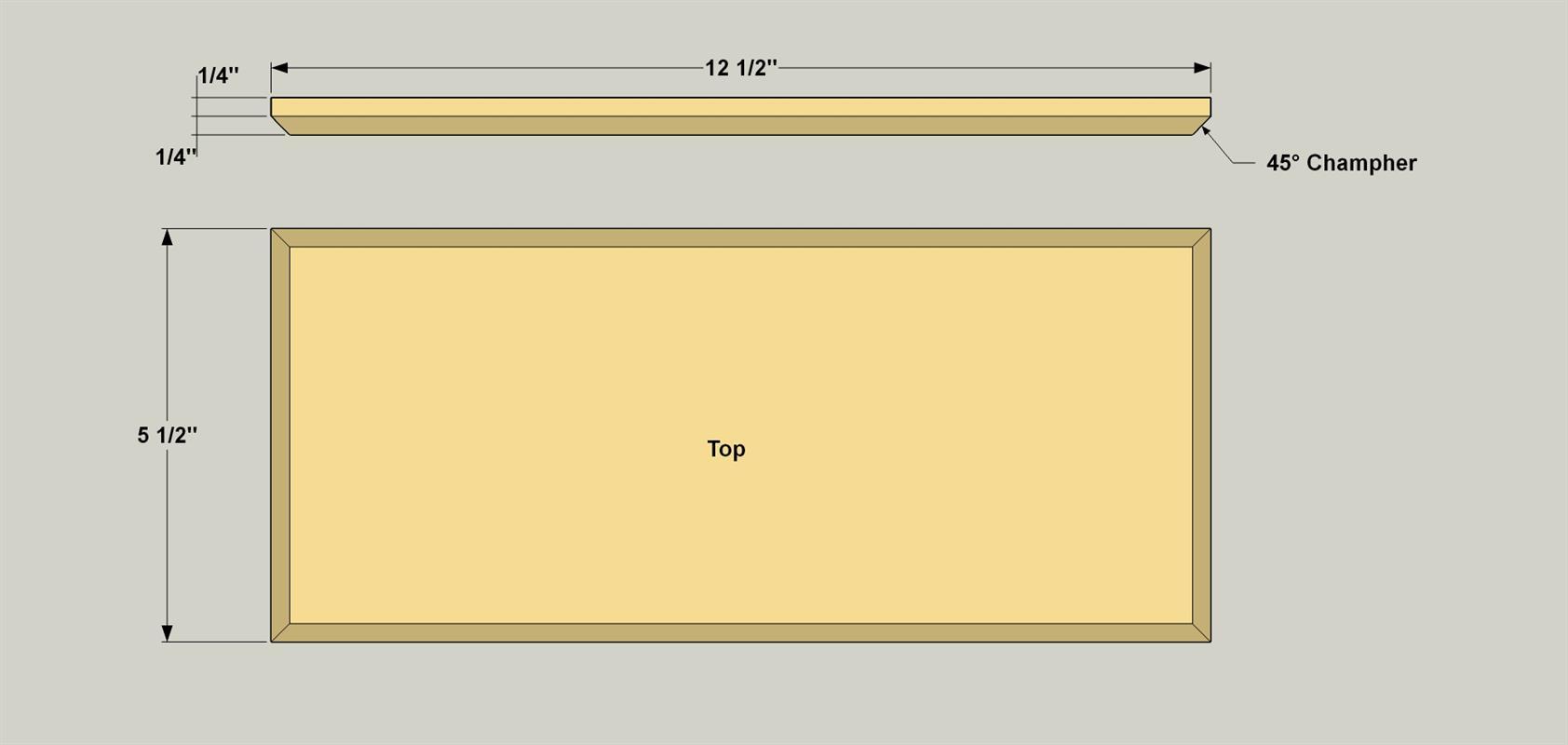

Make the Top

Cut the Top from 1/2" x 6 oak as shown in the cutting diagram. Then you can add the decorative profile on the lower edges, as shown. It’s called a chamfer, and it’s just a 45° bevel. The easiest way to create the chamfer is with a trim router and a chamfer bit set at 1/4" depth. You could also use a plane, a file, or sandpaper to create this profile. After creating the chamfer, sand it and the rest of the Top smooth.

-

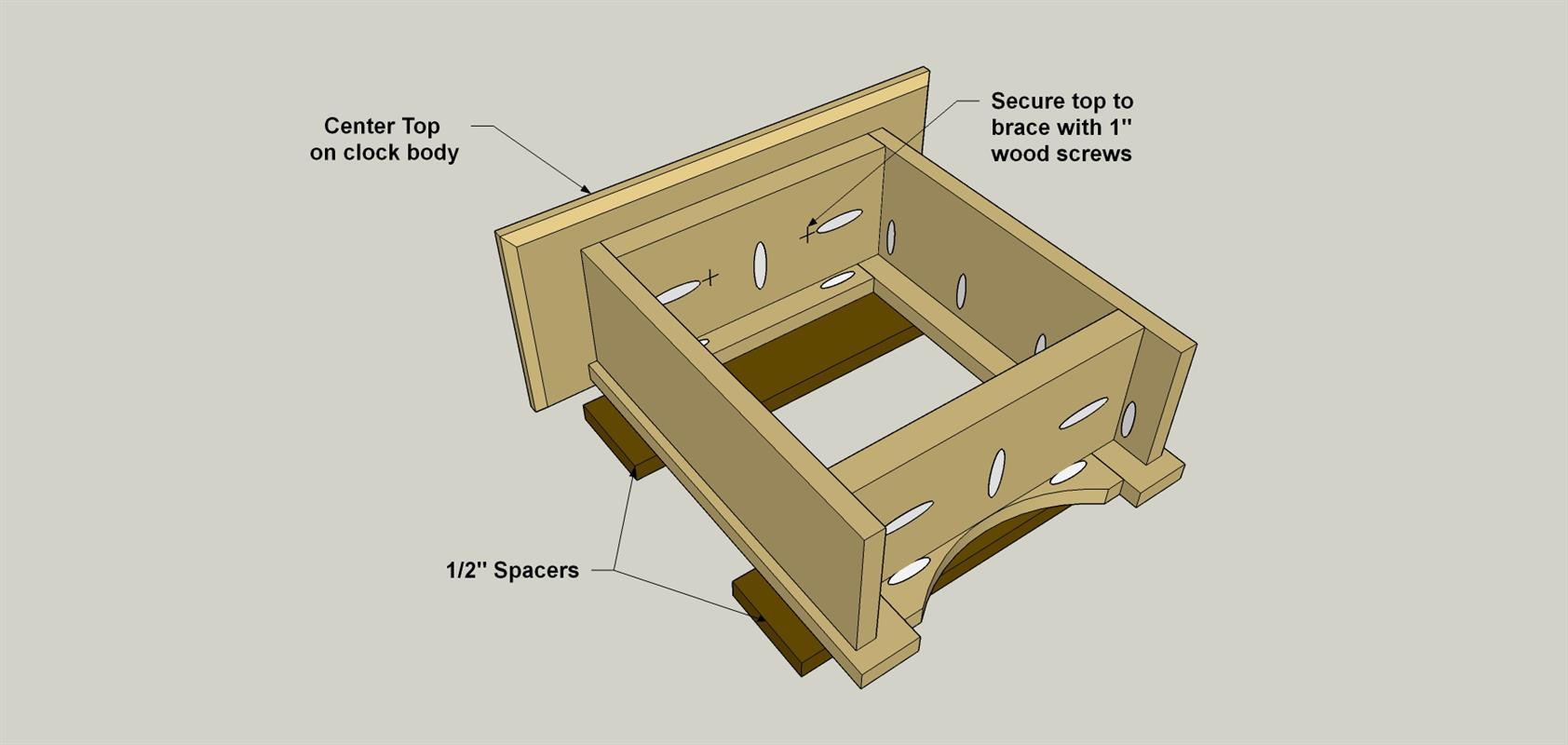

Secure the Top to the Top Brace

On a flat work surface, place the clock assembly on a couple 1/2" spacers as shown. Set the Top against the Top Brace, center it from side to side, and secure it with two 1" flat-head wood screws.

-

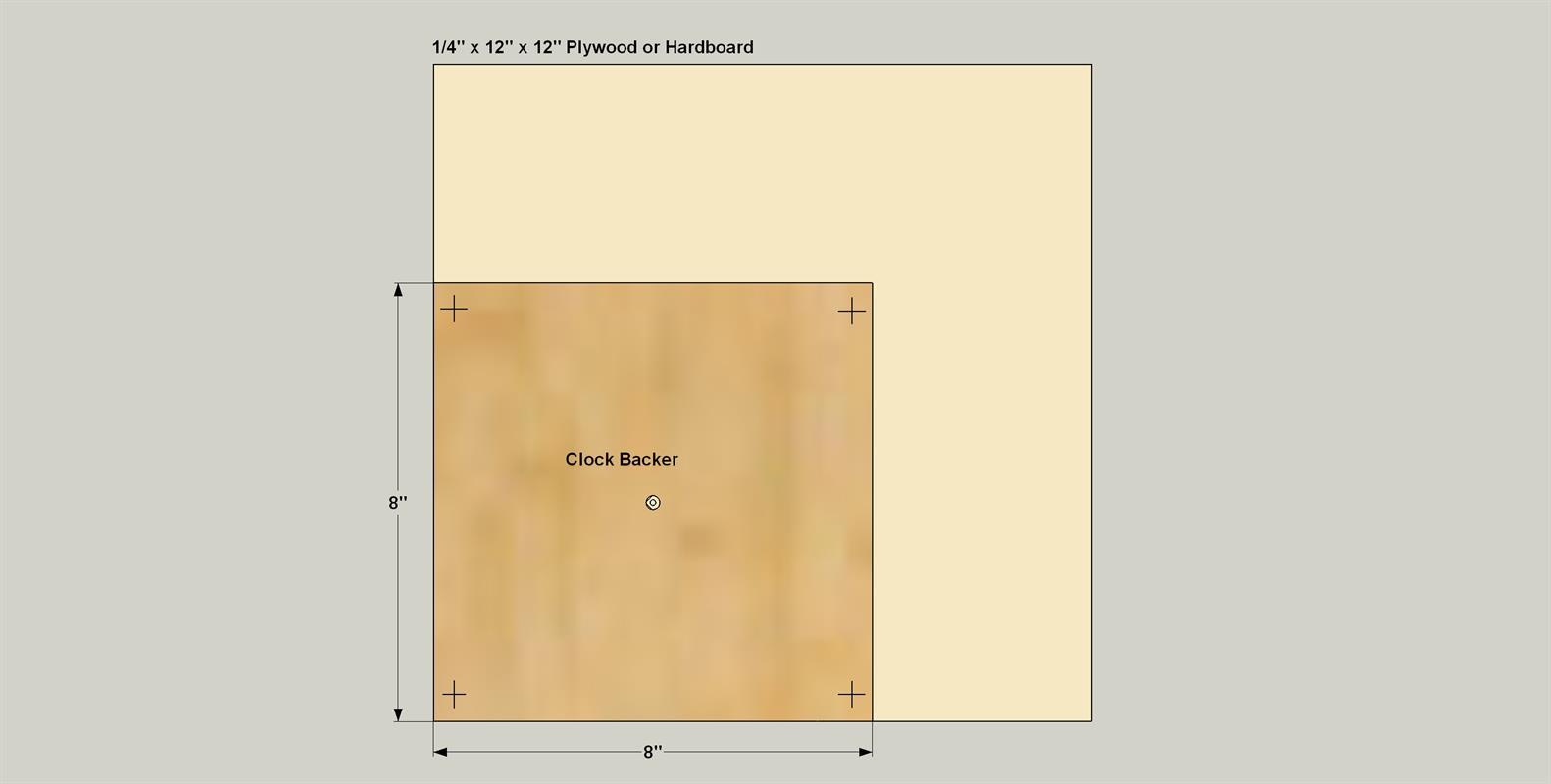

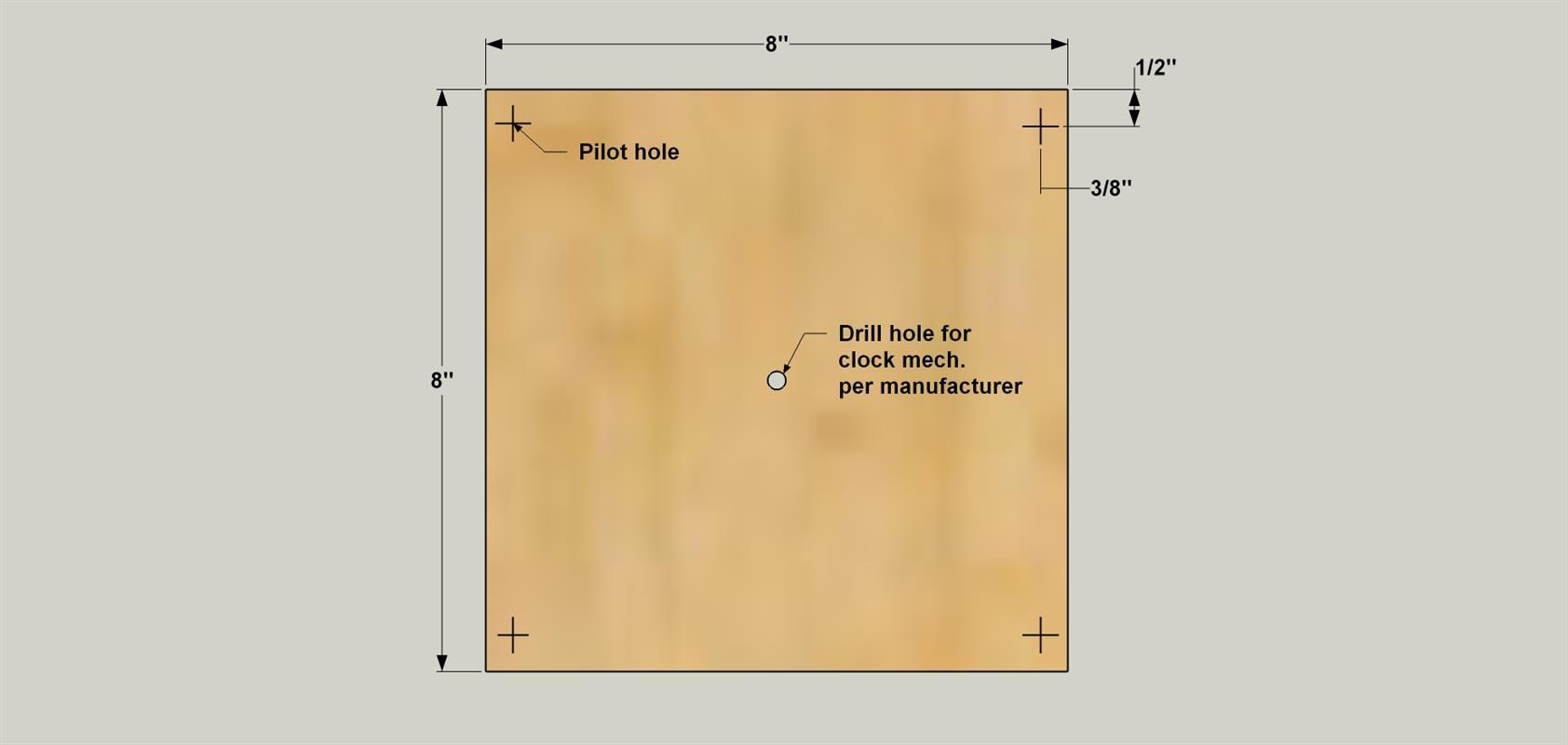

Print and Make the Clock Dial

Click on the “Extras” tab (below the main project photo) to find the pdf clock dial we’ve provided. Print the dial on a heavy art paper. Then cut out the dial. Cut a Clock Backer to size from 1/4" hardboard or plywood, as shown in the cutting diagram. Following the instructions with your clock kit, drill a hole in the center of the board for the clock shaft. Now drill four pilot holes at the locations shown to attach the Backer to the front frame of the clock. Sand the faces of the clock smooth, Make sure the Backer or the printed dial are clean, center the dial, and then and then adhere it to the Backer with a spray adhesive. You can find this adhesive in any home center. Cut the center hole out of the dial with a utility knife.

-

Sand, Stain, and Finish

Before you move with the rest of the final assembly, it’s a good time to stain and finish your clock. That way, you don’t have to worry about getting stain on the printed dial. First, check over your clock and do any final sanding that’s needed. Then apply the stain or finish of your choice. We used a “java” stain, followed by a couple of coats of wipe-on varnish. On that back frame, don’t forget to apply stain and finish on both faces.

-

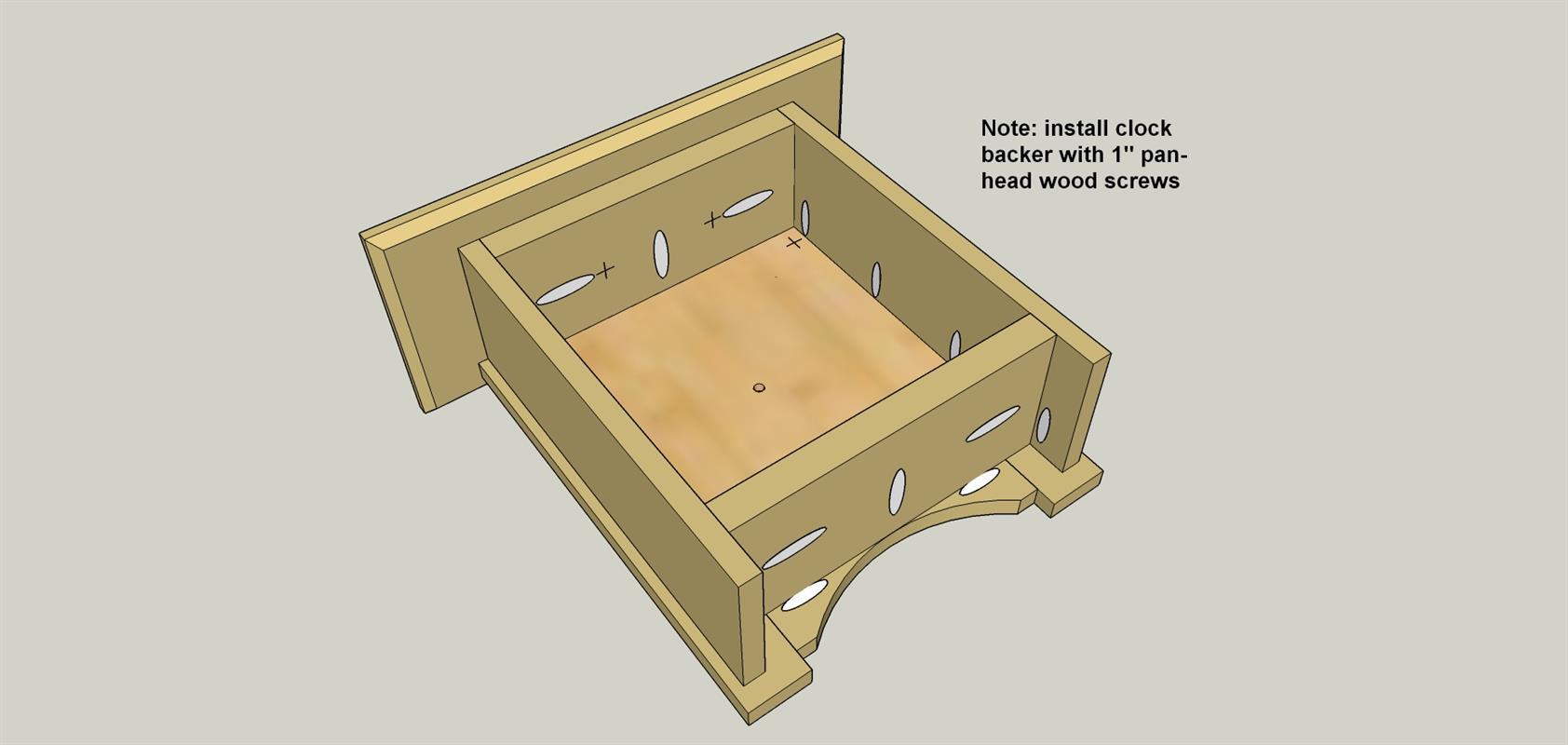

Attach the Clock Backer

After the stain and finish dry, you can set the backer/dial assembly in position inside the clock so it sits against the inside of the front frame. Make sure that the dial is right side up! Secure the backer with four 1/2" pan-head wood screws.

-

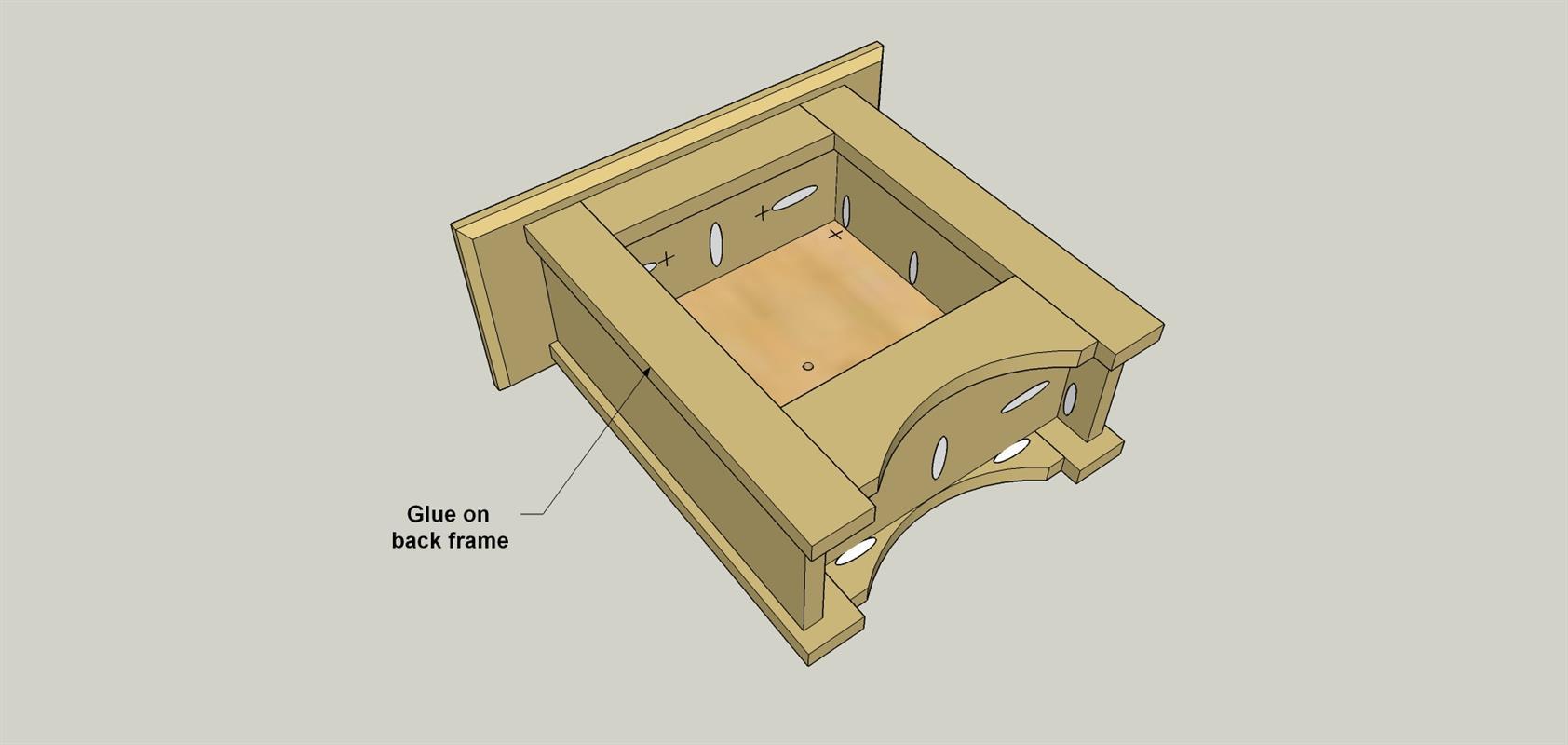

Glue on the Back Frame

Apply glue to the exposed edges of the Sides and Braces, then place the back frame in position with pocket holes facing the inside of the clock. Make sure the frame overhangs the Sides equally. Then use clamps or masking tape to hold the rear frame in place while the glue dries.

-

Install the Clock Movement

Install the mechanism and hands following the manufacturer's instructions. If the hands are longer than you’d like, you can trim the tips off.