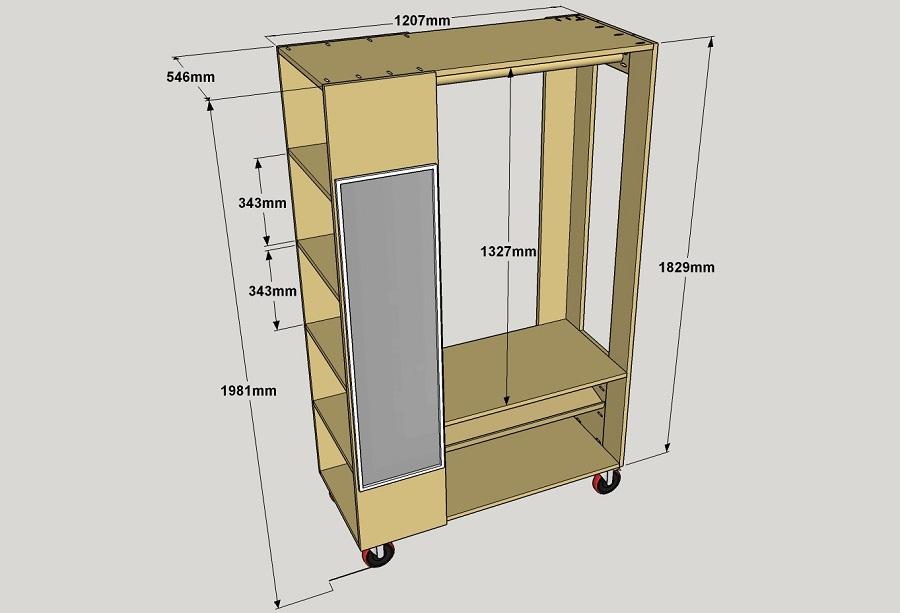

Freestanding Closet – Metric

By Kreg ToolClosets are kind of like potato chips. No matter how many you have, it would always be great to have just one more. Of course, finding space for another closet is challenging, if not impossible. That’s why this freestanding closet is great. It provides an extra closet anywhere you need one.

Directions

-

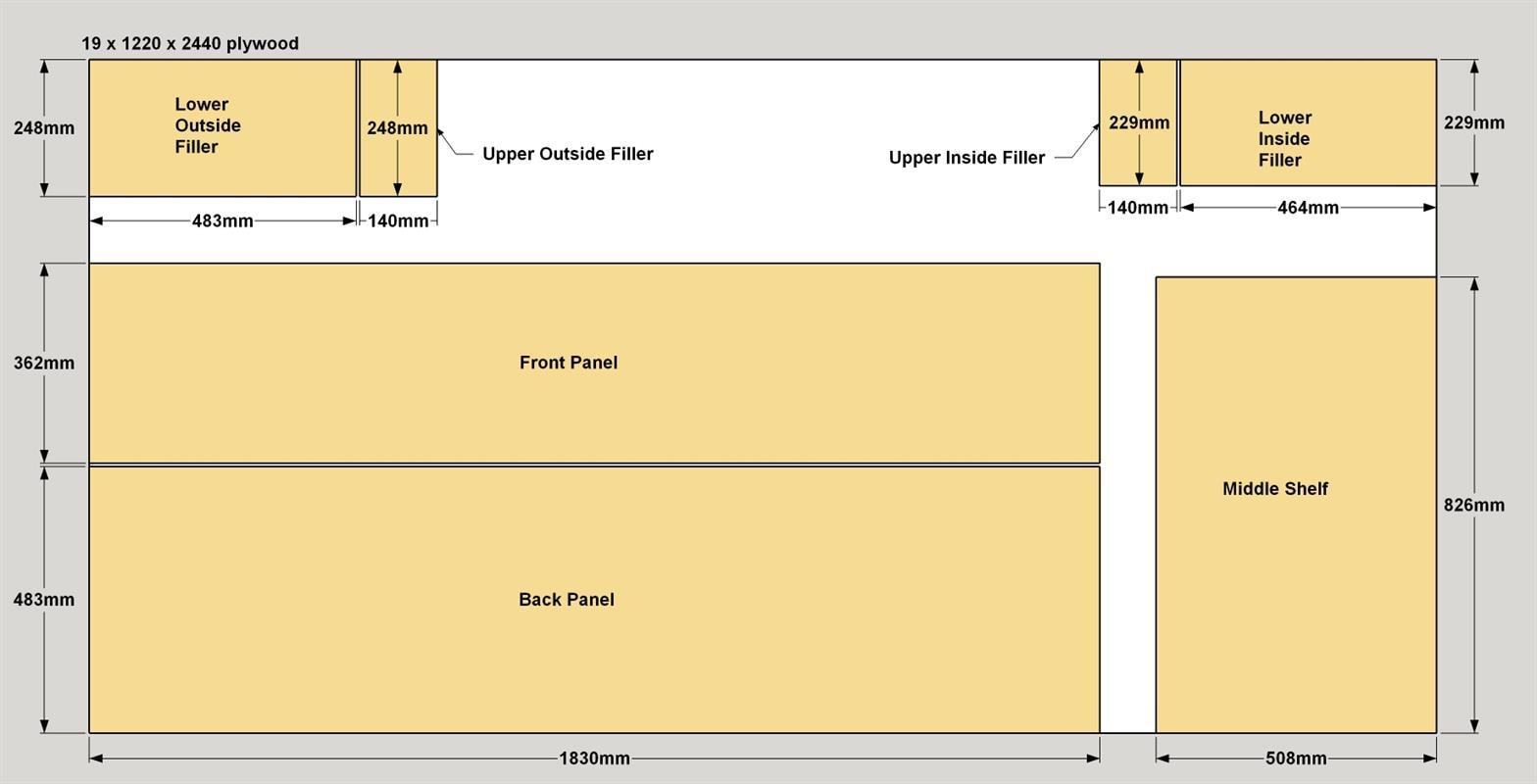

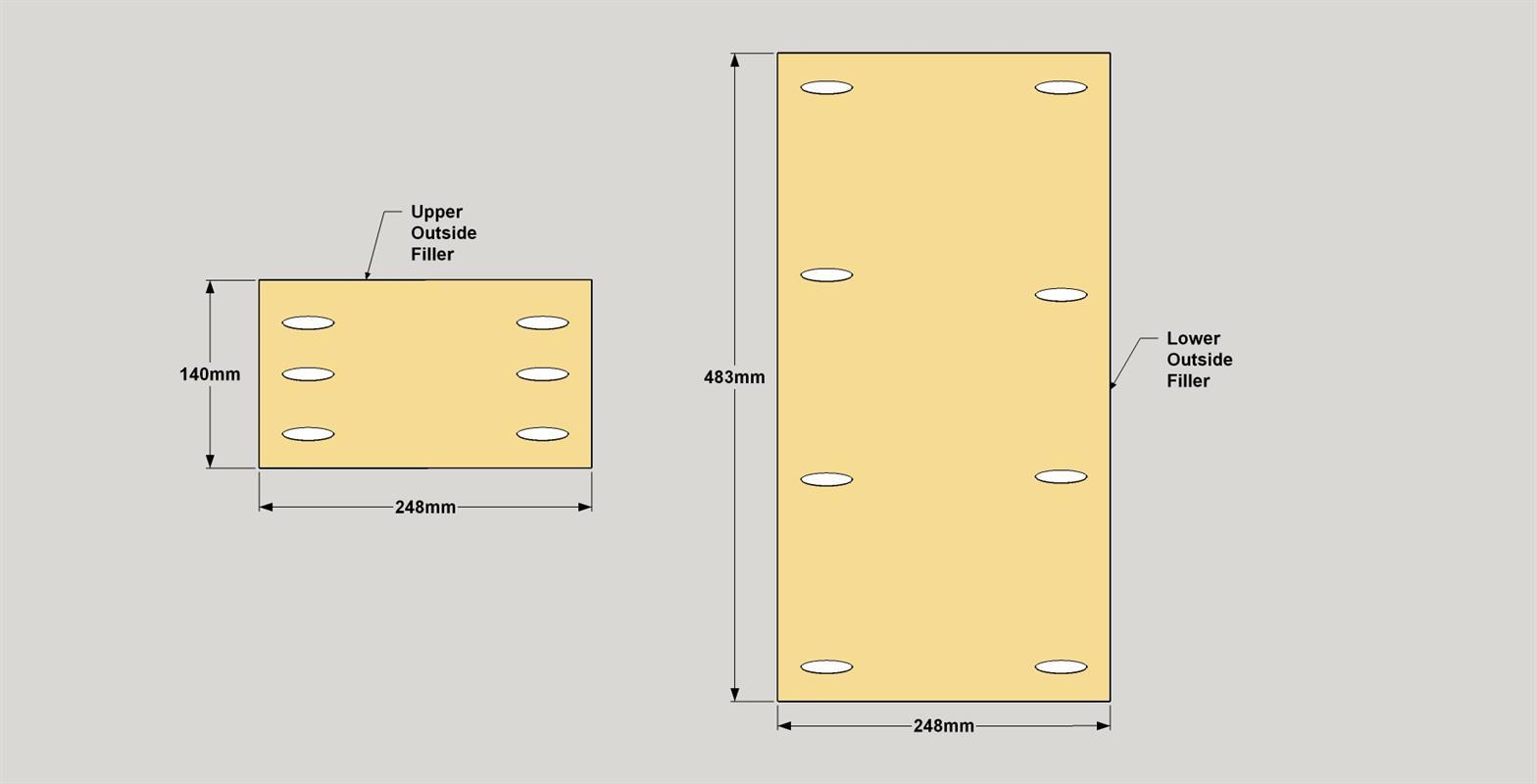

Create Outside Frame Fillers

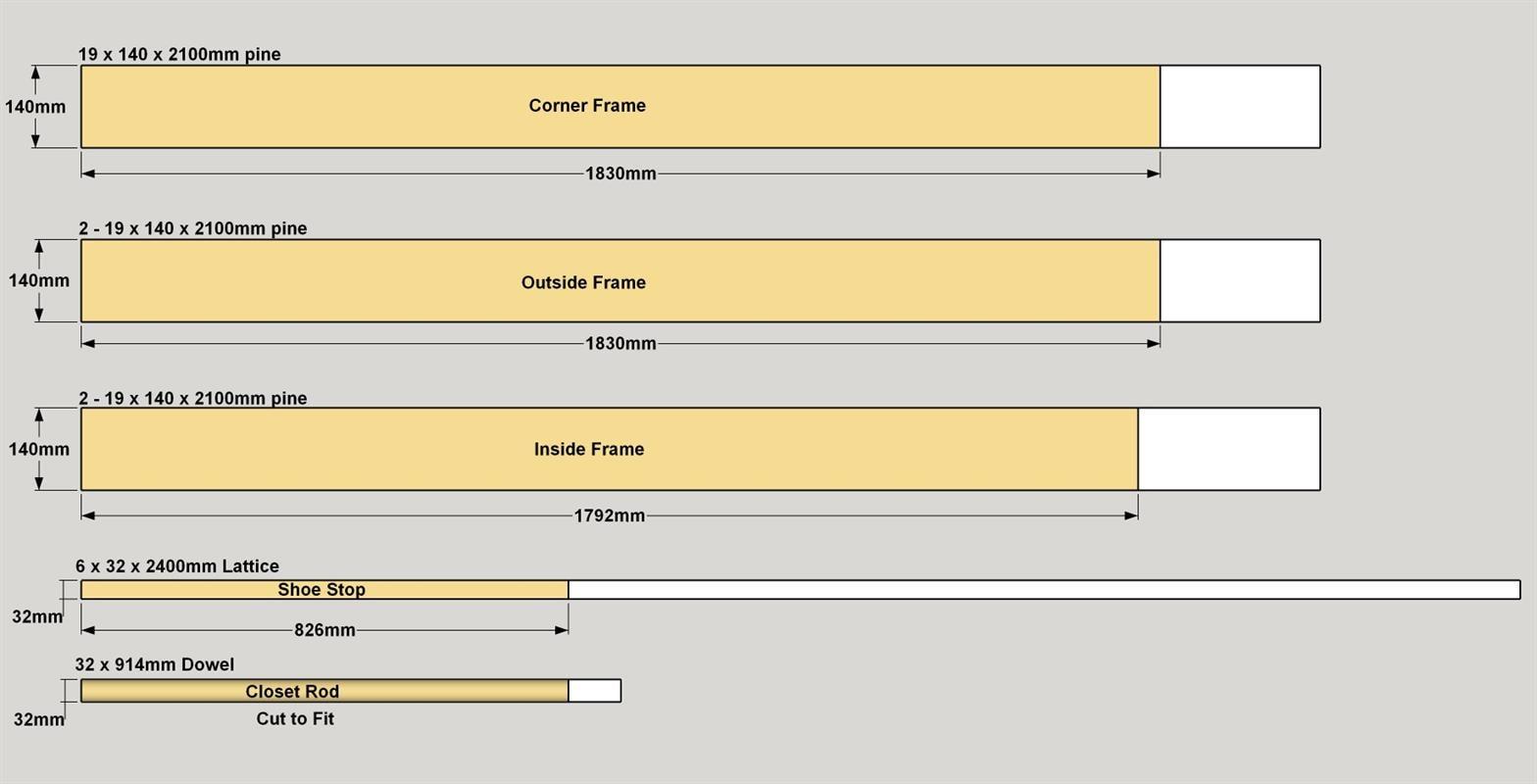

Cut one Lower Outside Filler and one Upper Outside Filler to size from 19mm plywood, as shown in the cutting diagram. Set your pocket-hole jig for 19mm thick material, and then drill pocket holes in in the Fillers. The exact location of these pocket holes isn’t critical, just space them approximately as shown.

-

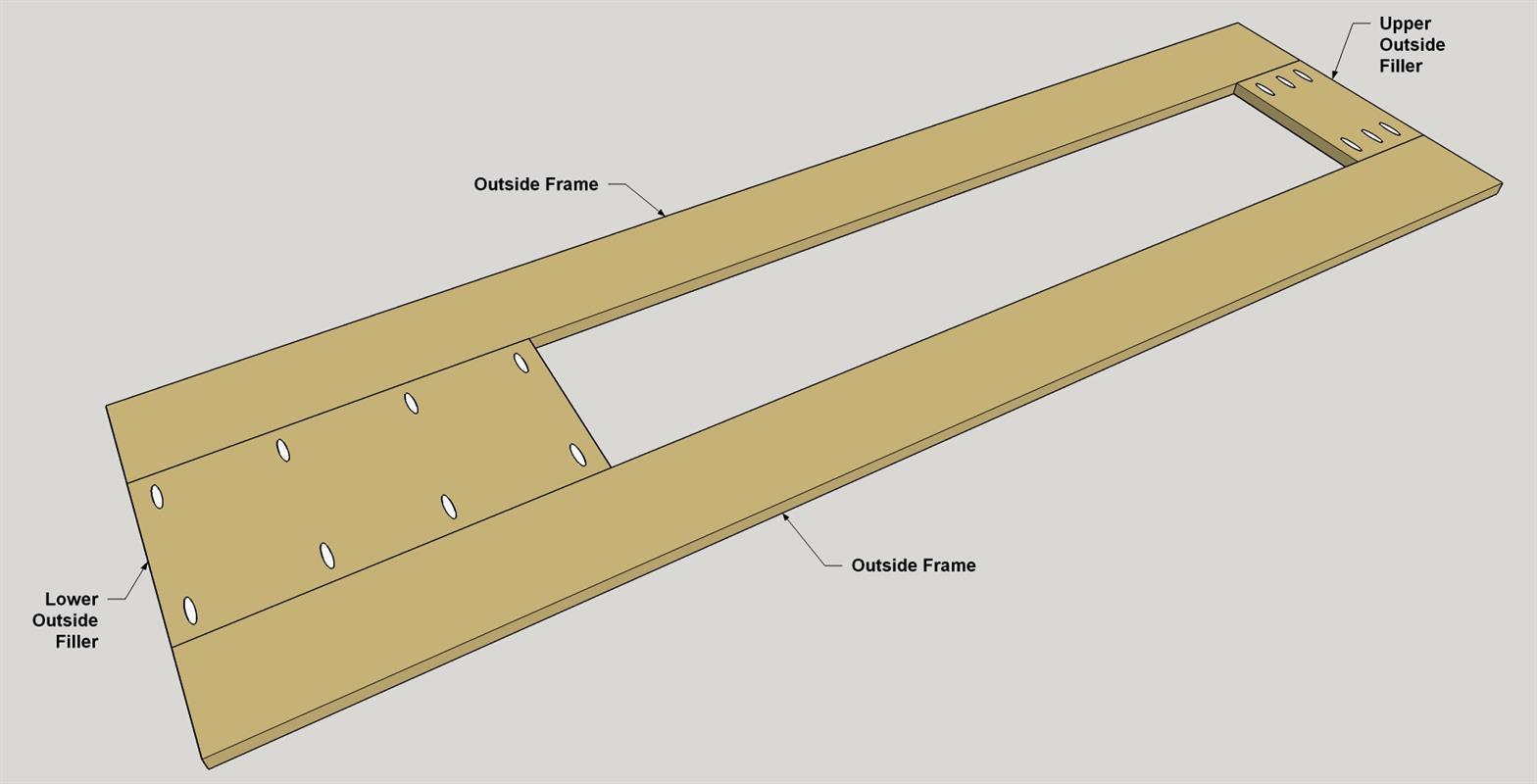

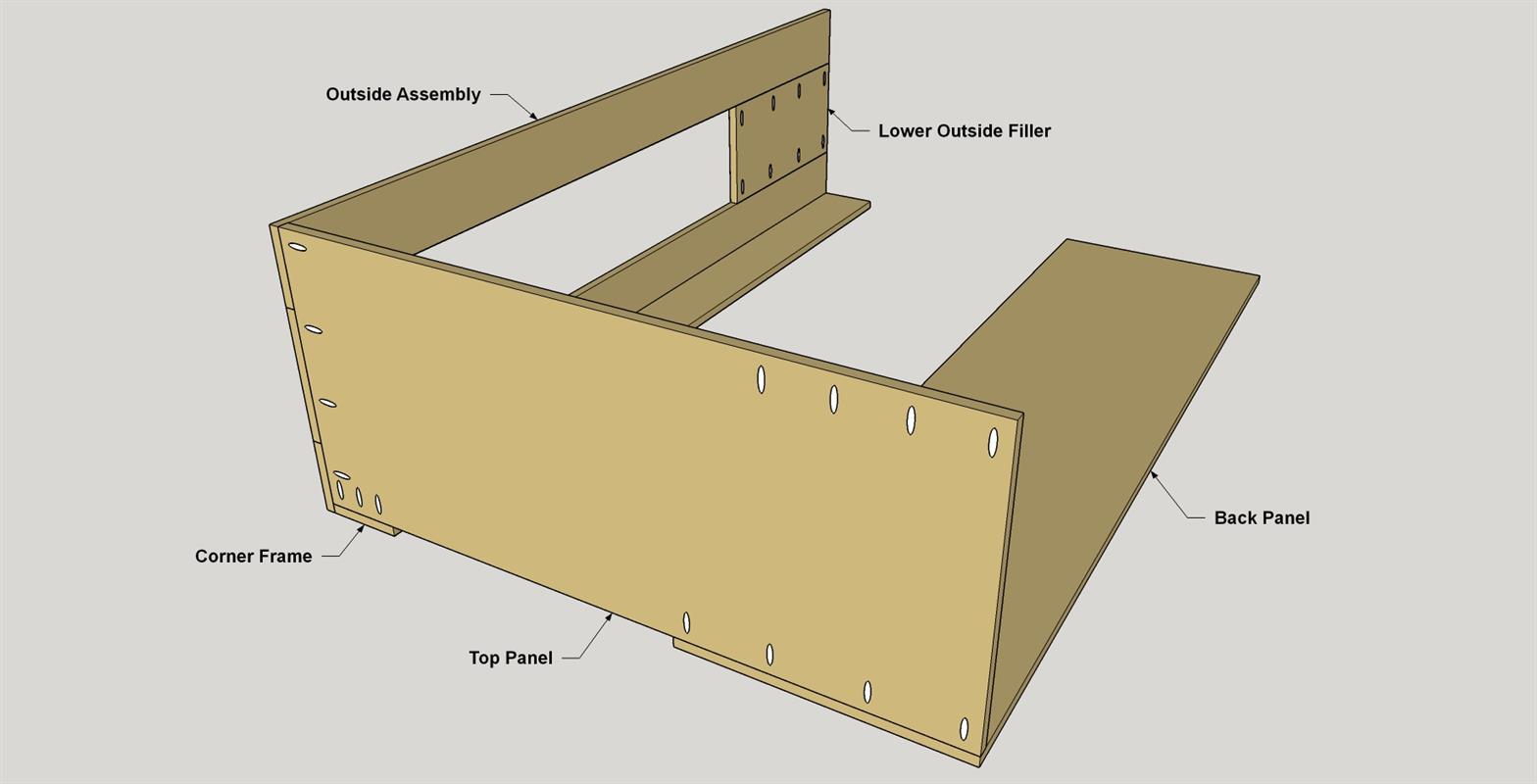

Assemble the Outside Frame

Next, cut two Outside Frames to length from 19x140mm boards. Double check the length of the boards. Then join the Outside Frames to the Upper Outside Filler and the Lower Outside filler using 32mm coarse-thread pocket-hole screws to create an outside assembly. Sand the assembly smooth, as needed, using 120-grit sandpaper.

-

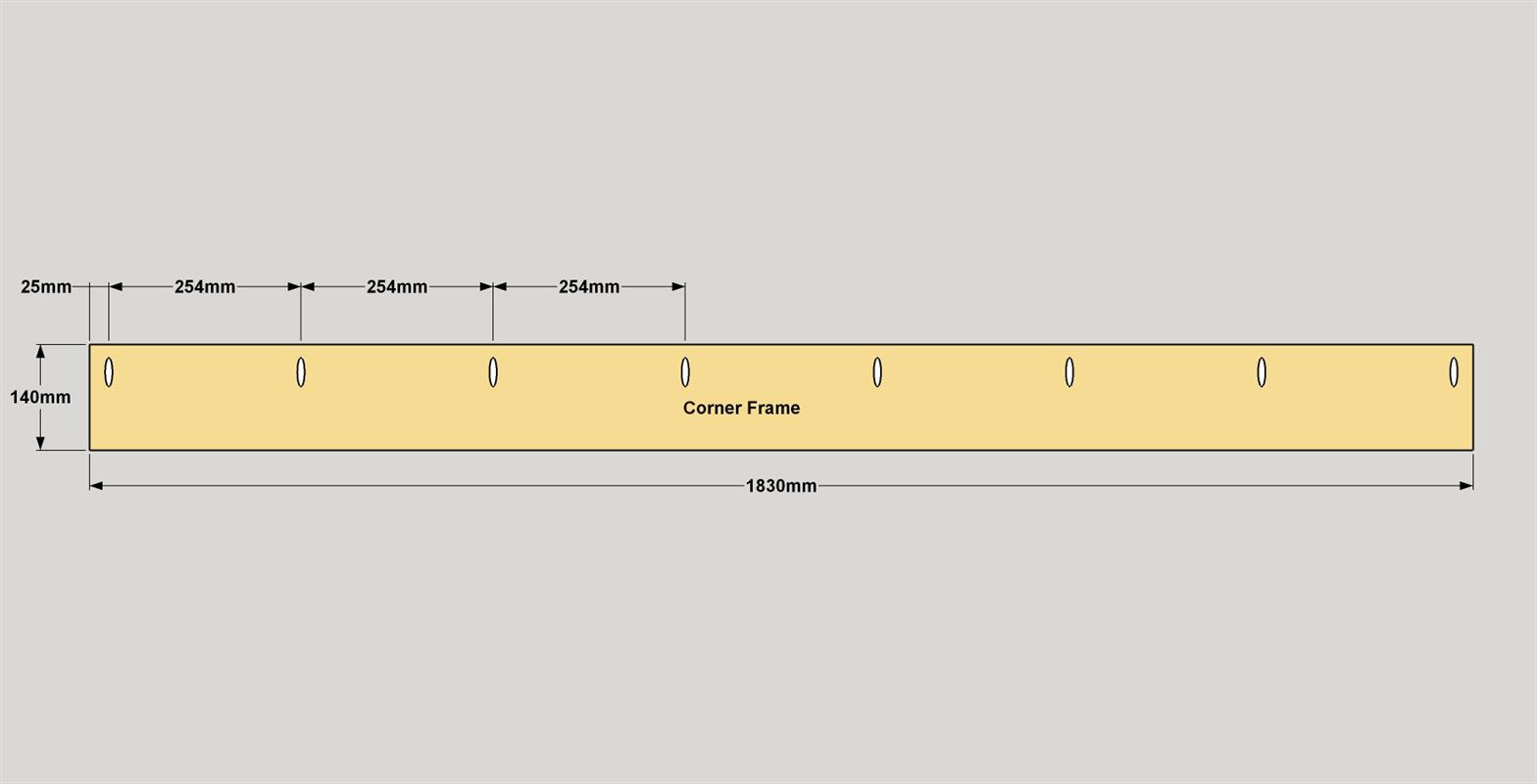

Create a Corner Frame

Now attach the Corner Frame to the outside frame assembly using 32mm coarse-thread pocket-hole screws, as shown.

-

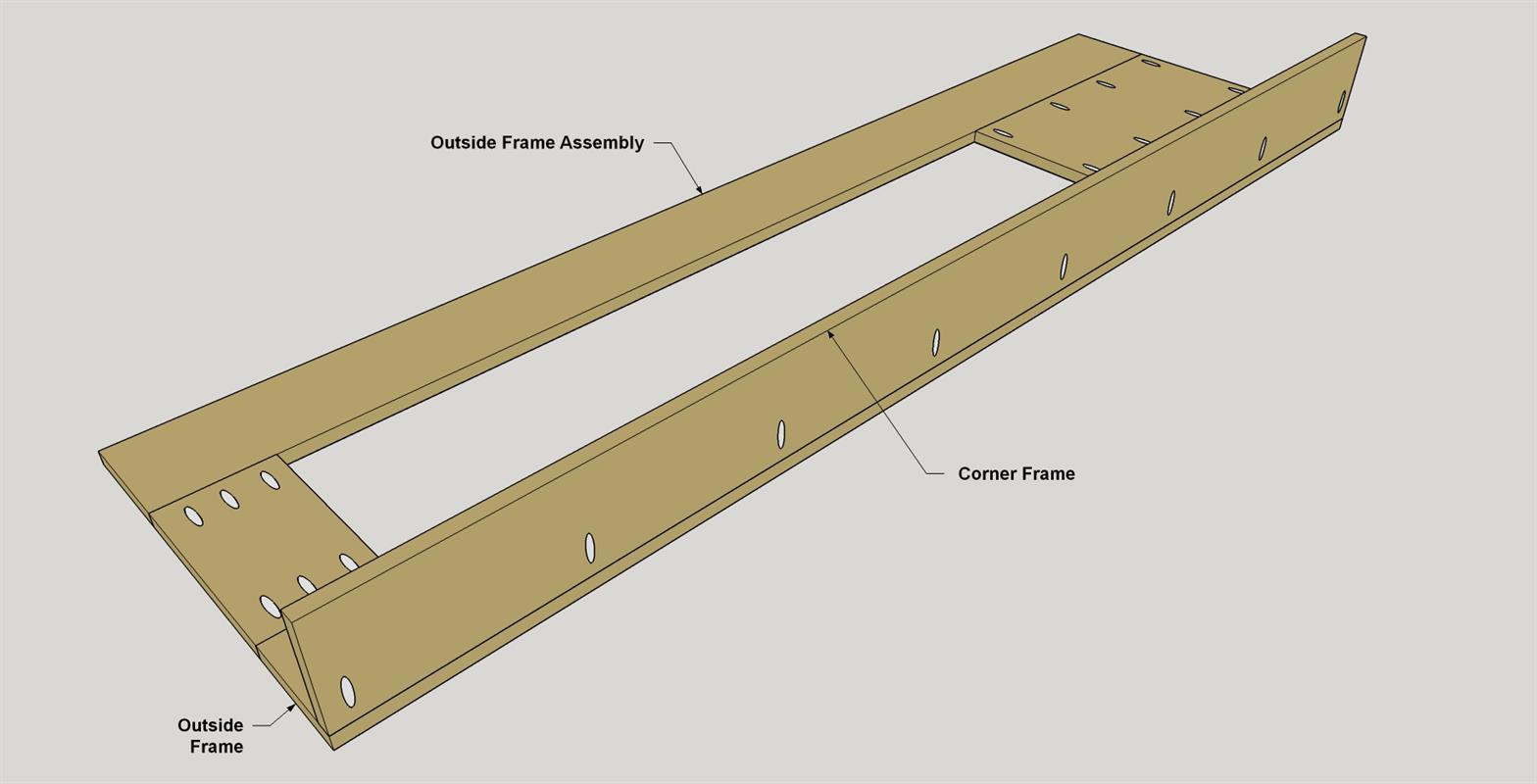

Attach the Corner Frame

Now attach the Corner Frame to the outside frame assembly using 32mm coarse-thread pocket-hole screws, as shown.

-

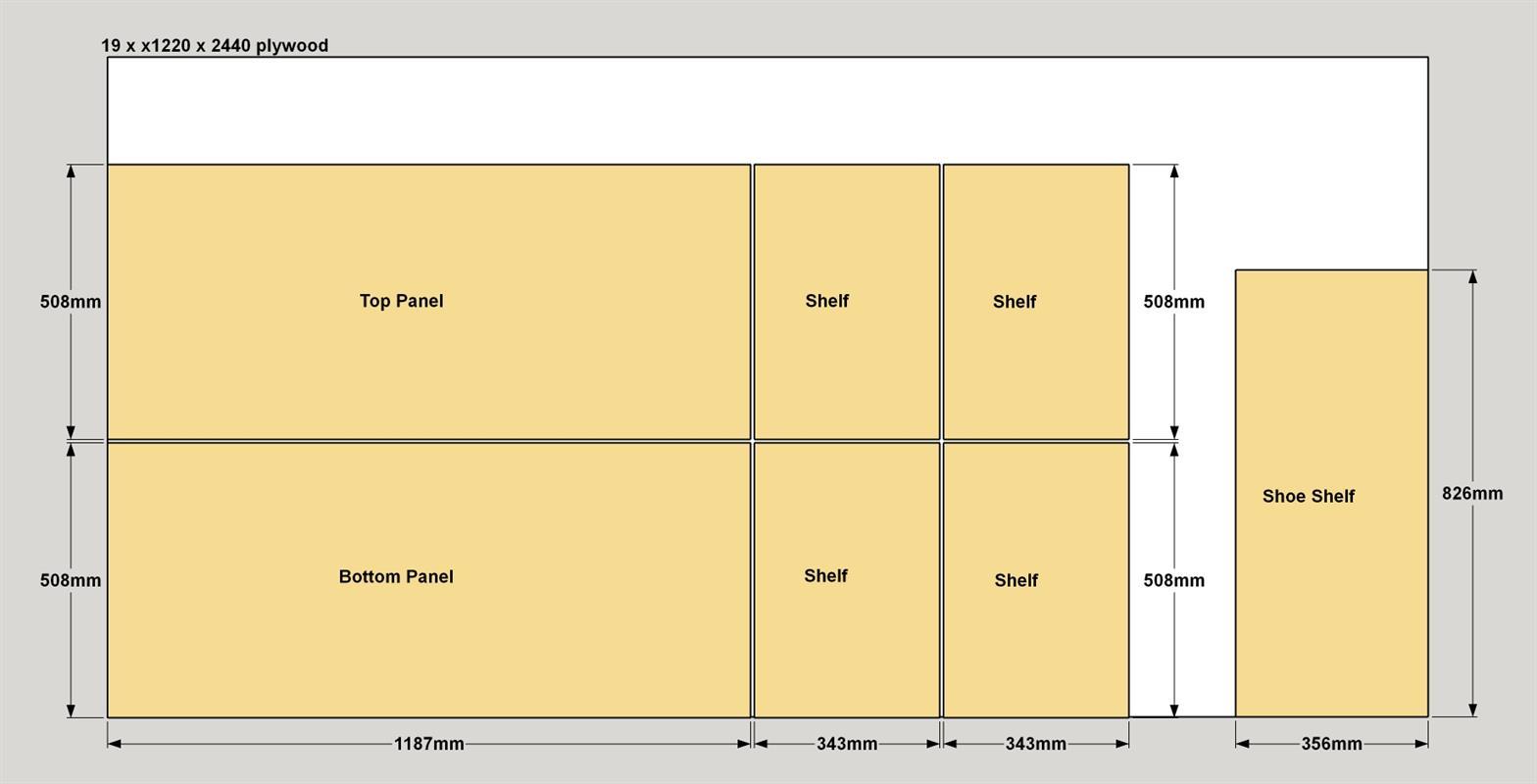

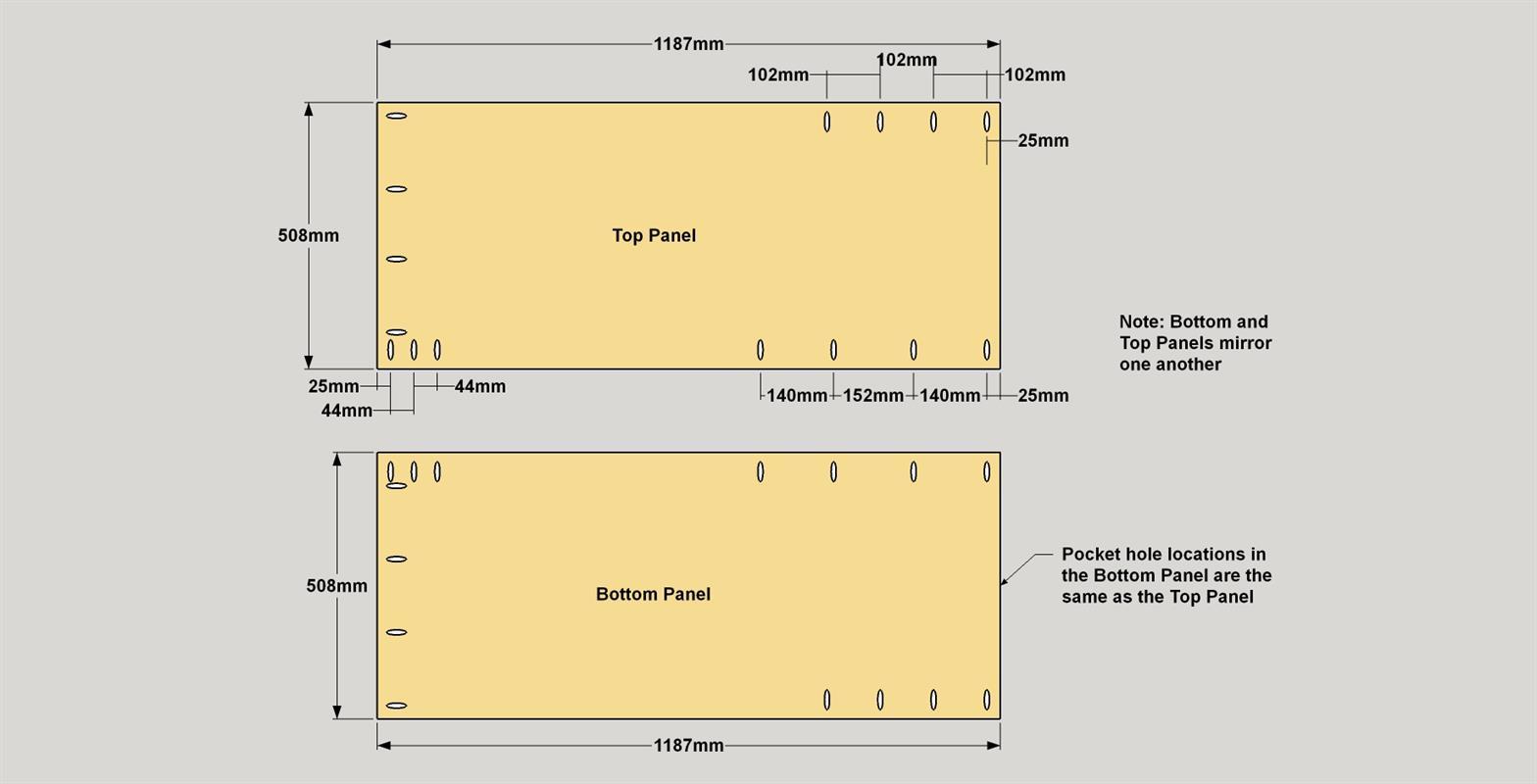

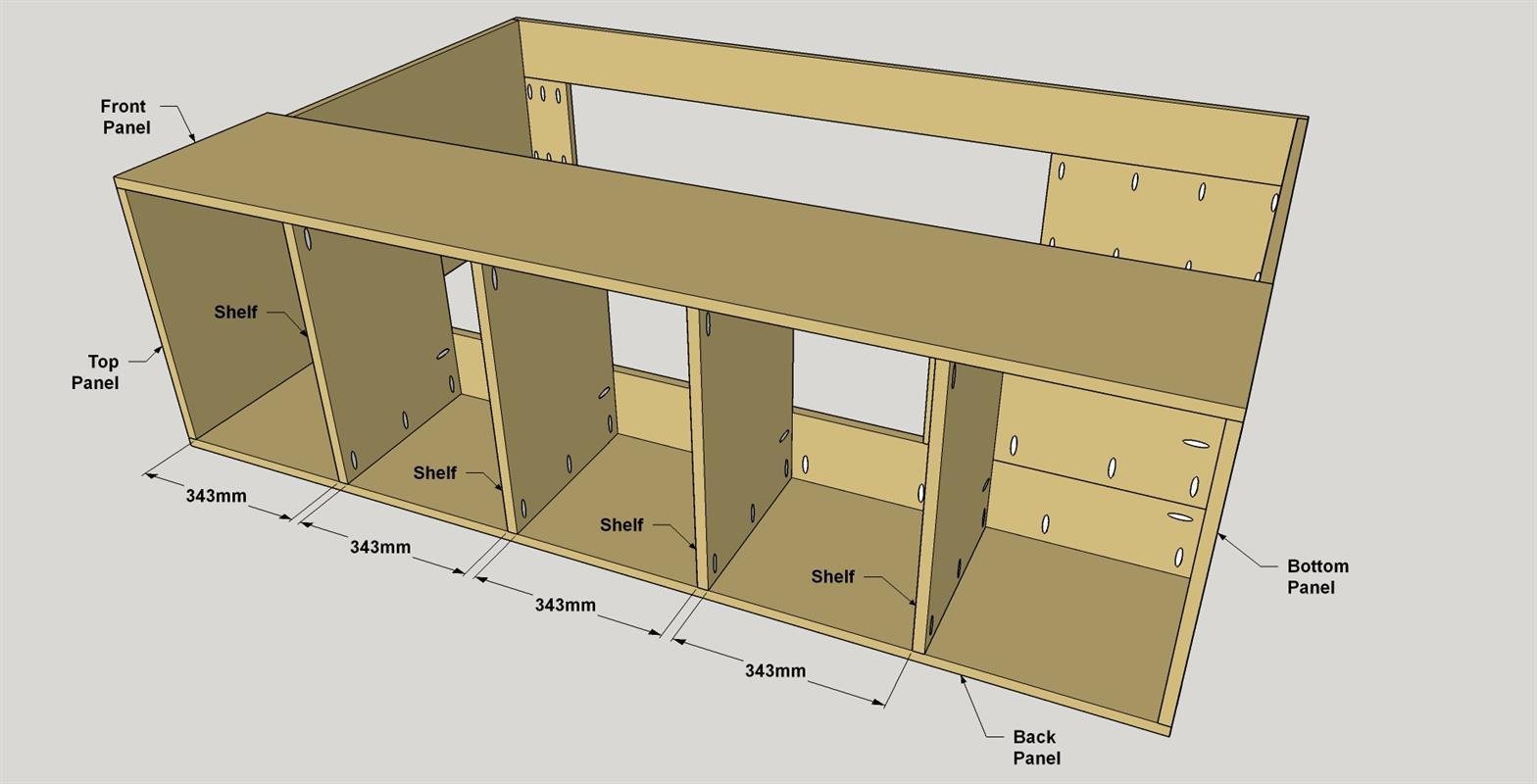

Make the Top, Bottom, Front, Back

Cut one Top Panel and One Bottom Panel to size from 19mm plywood, as shown in the cutting diagram. While you’re at it, you can cut the Back Panel and Front Panel, as well. For the moment, set the Back Panel and Front Panel aside. Next, lay out the location of the pocket holes in the Top Panel and Bottom Panel, as shown. You’ll notice that these panels are “mirror images” of one another. For these panels, it’s more important to position the pocket holes at defined locations. So, take your time to lay them out. Then, drill all of the holes. Sand the pieces as needed.

-

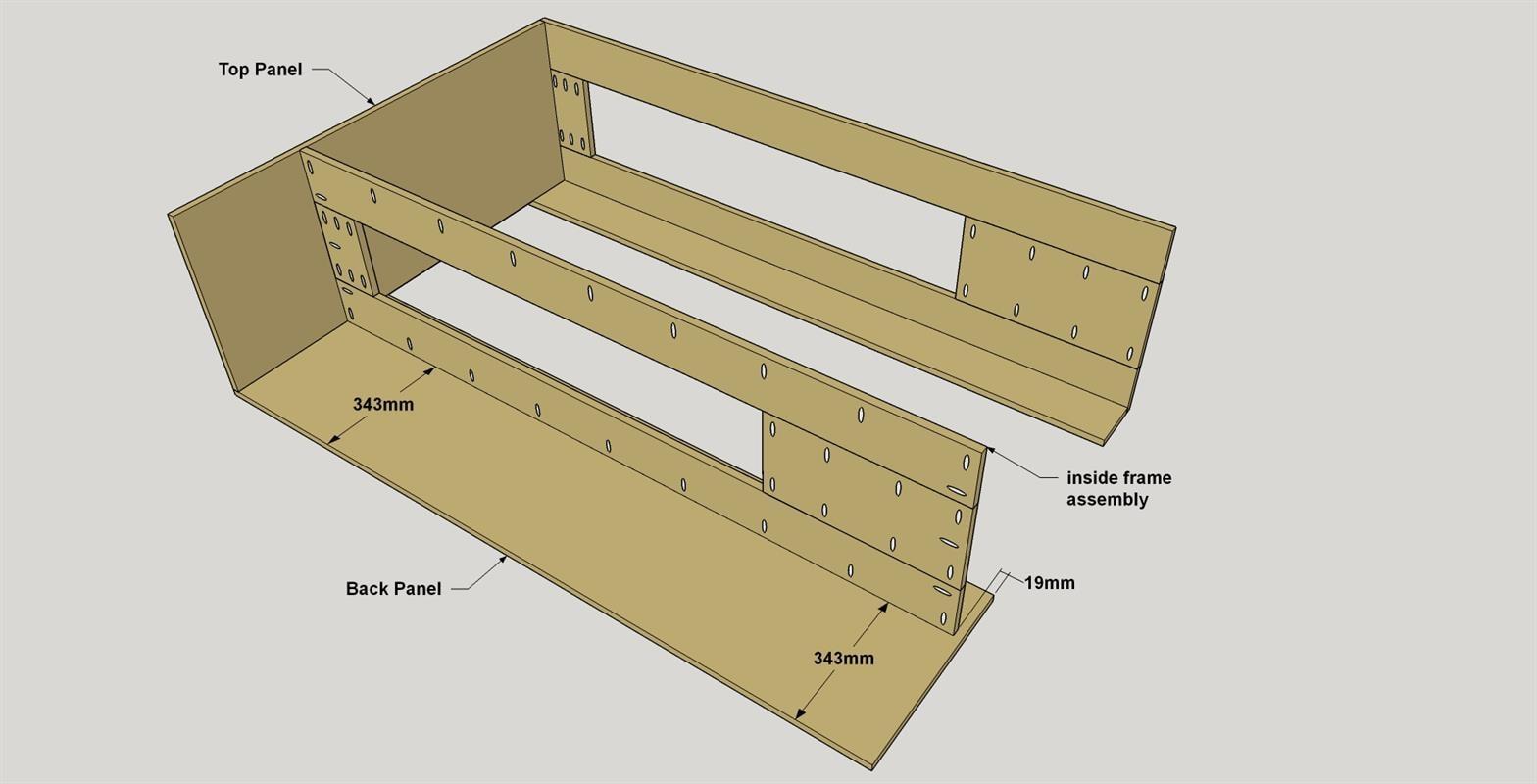

Start the Case Assembly

Lay the Back Panel and the outside/corner assembly on a flat work surface, as shown. Position the Top Panel as shown, and then attach it to the Back and corner assembly using 32mm coarse-thread pocket-hole screws.

-

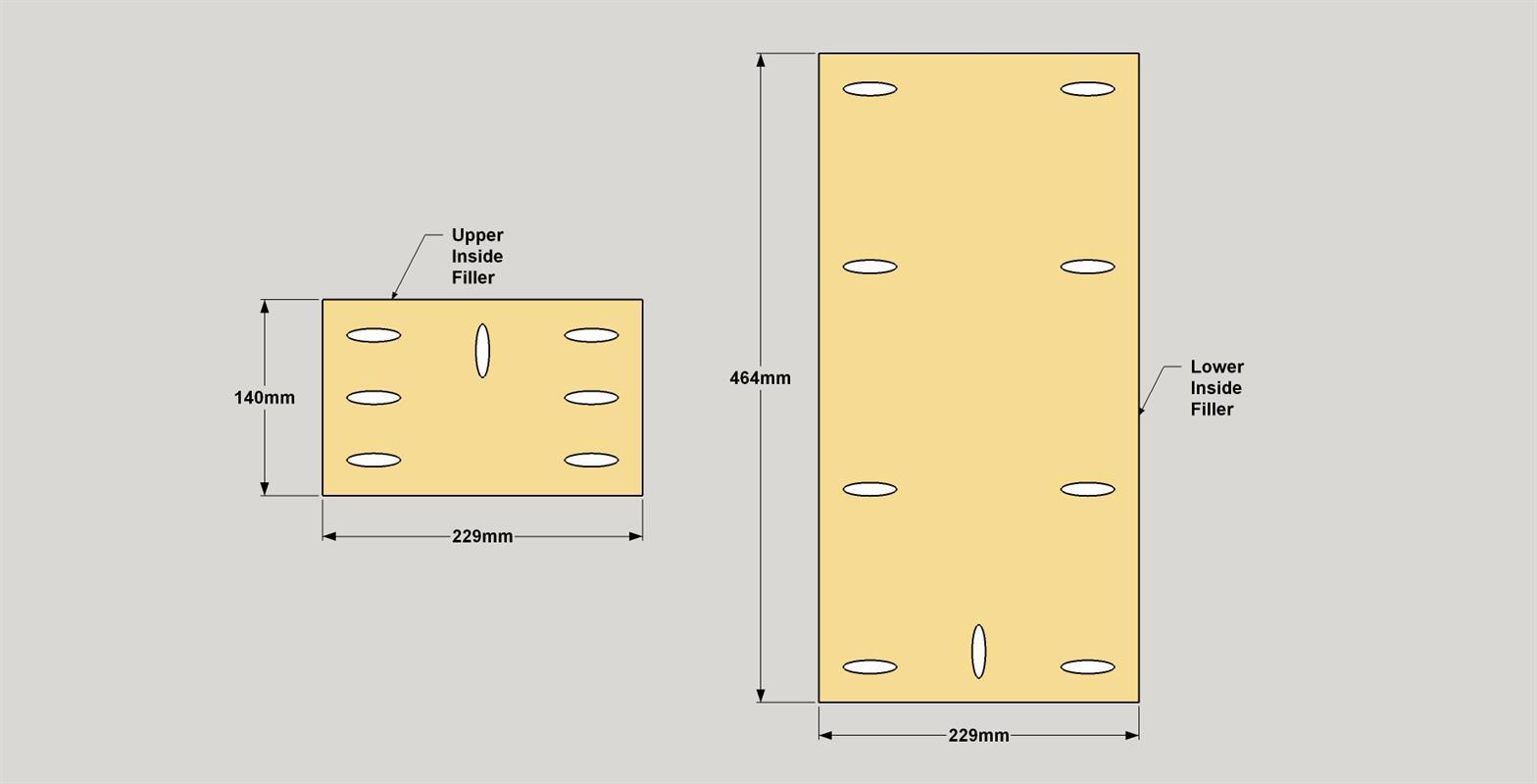

Create Inside Frame Fillers

Cut one Lower Inside Filler and one Upper Inside Filler to size from 19mm plywood, as shown in the cutting diagram. With your pocket-hole jig still set for 19mm thick material, drill pocket holes in the Fillers, as shown. Once again, the exact location of these pocket holes isn’t critical. Sand the pieces as needed.

-

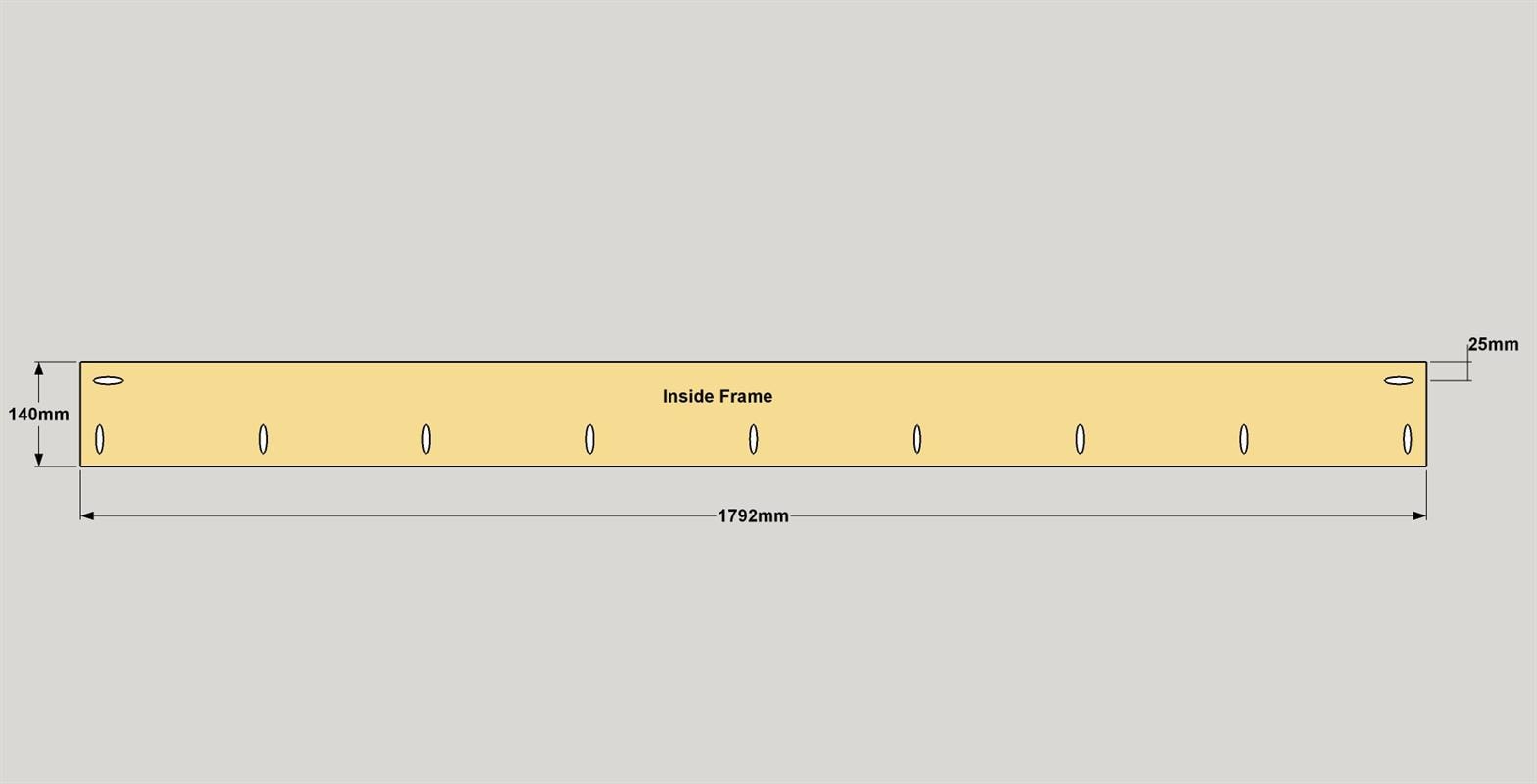

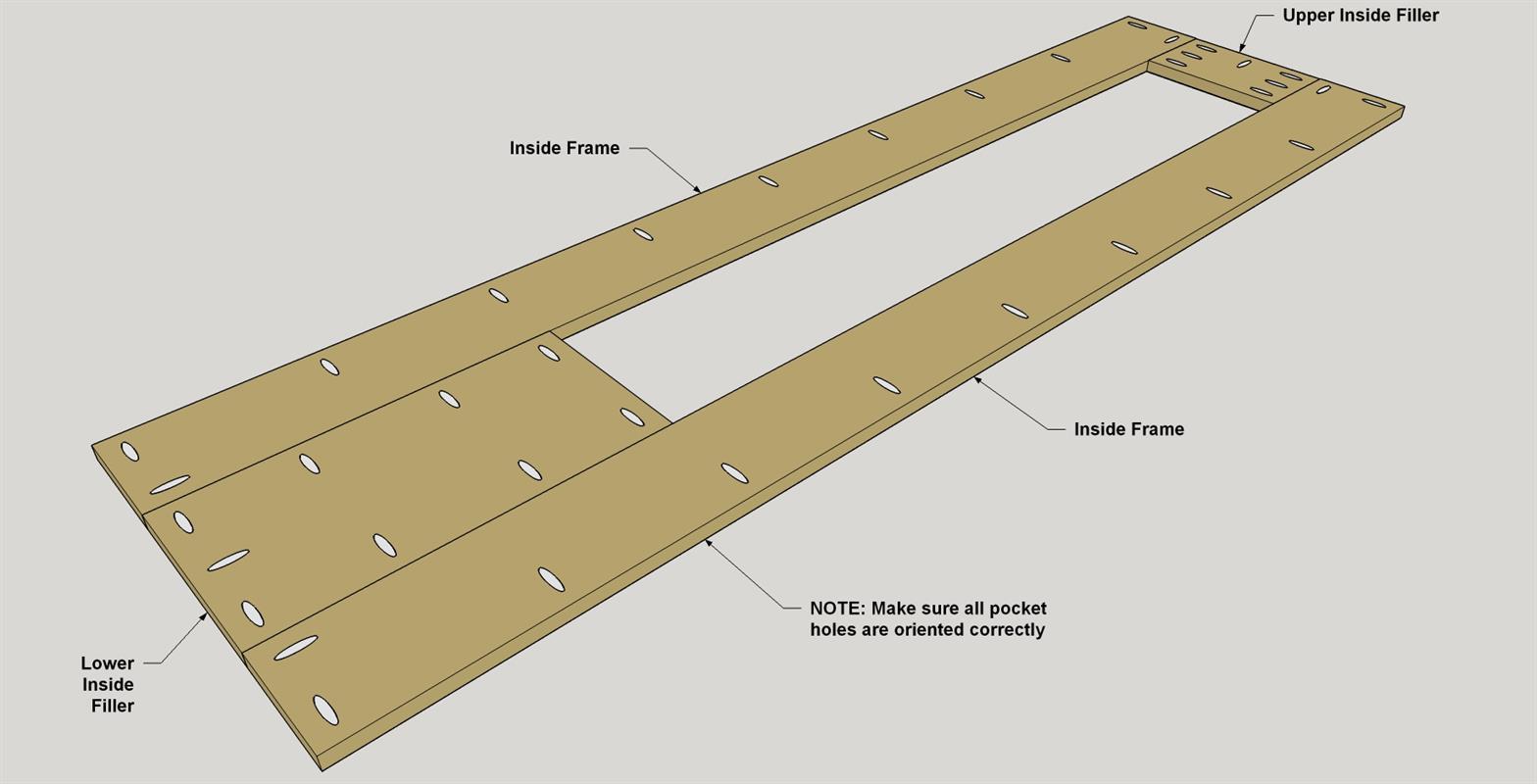

Create the Inside Frames

Cut two Inside Frames to length from 19x140mm boards, as shown in the cutting diagram. Drill pocket holes in each board at the locations shown. Sand the pieces as needed.

-

Attach the Inside Frame

Attach the inside frame assembly to the Top Panel and the Back Panel, as shown. Make sure that the frame is straight. You’ll see that this assembly stops 19mm short of the lower end of the Back Panel. This is correct. The Bottom Panel will fit into this gap.

-

Assemble the Inside Frame

Now you can attach the Upper Inside Filler and Lower Inside Filler to the Inside Frames, as shown, using 32mm coarse-thread pocket-hole screws. Make sure that all of the pocket holes are oriented correctly before you screw everything together.

-

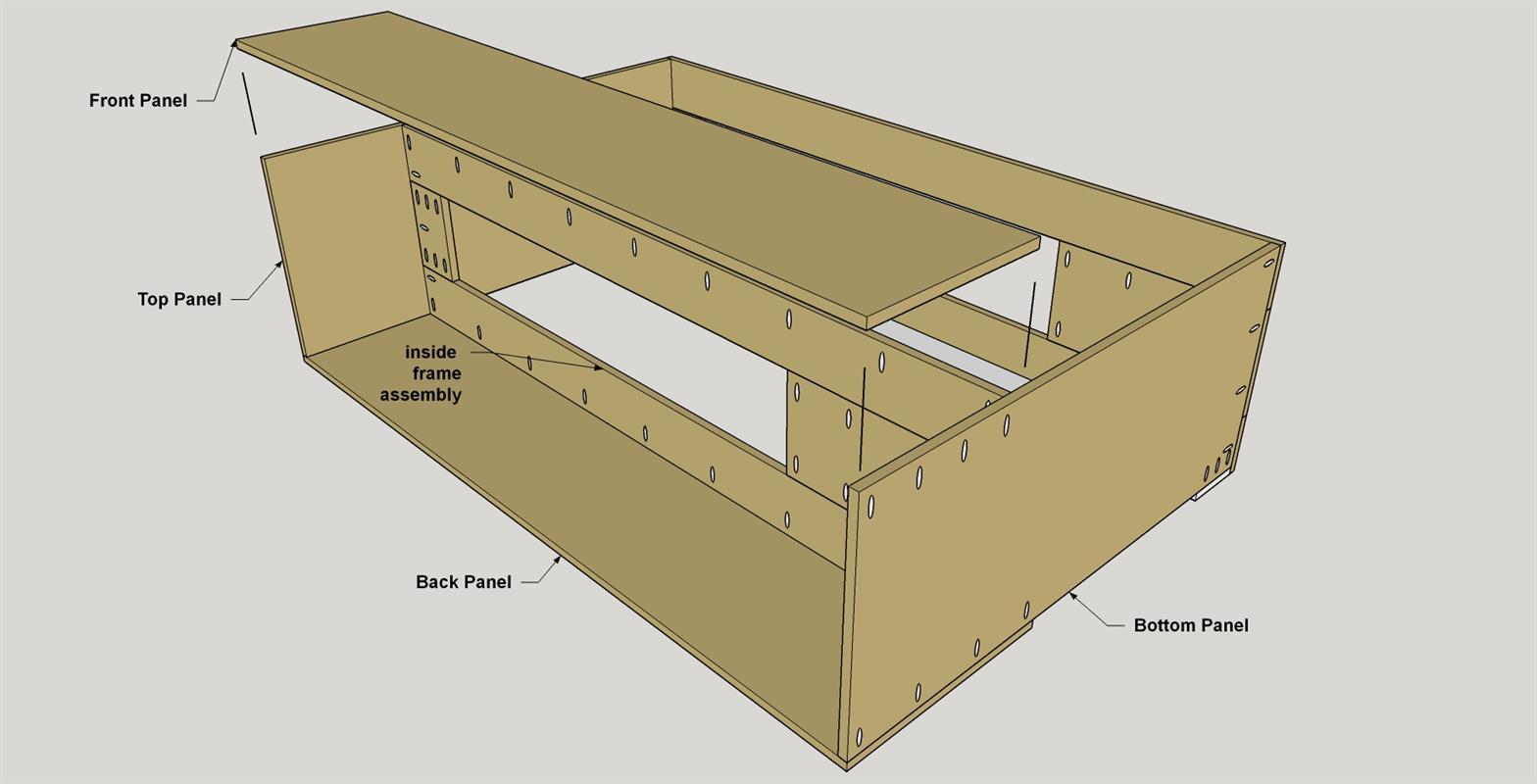

Attach the Bottom and Front

To complete the main case, you just need to attach the Bottom Panel and the Front Panel using 32mm coarse-thread pocket-hole screws. Attach the Bottom first, then add the Front, as shown.

-

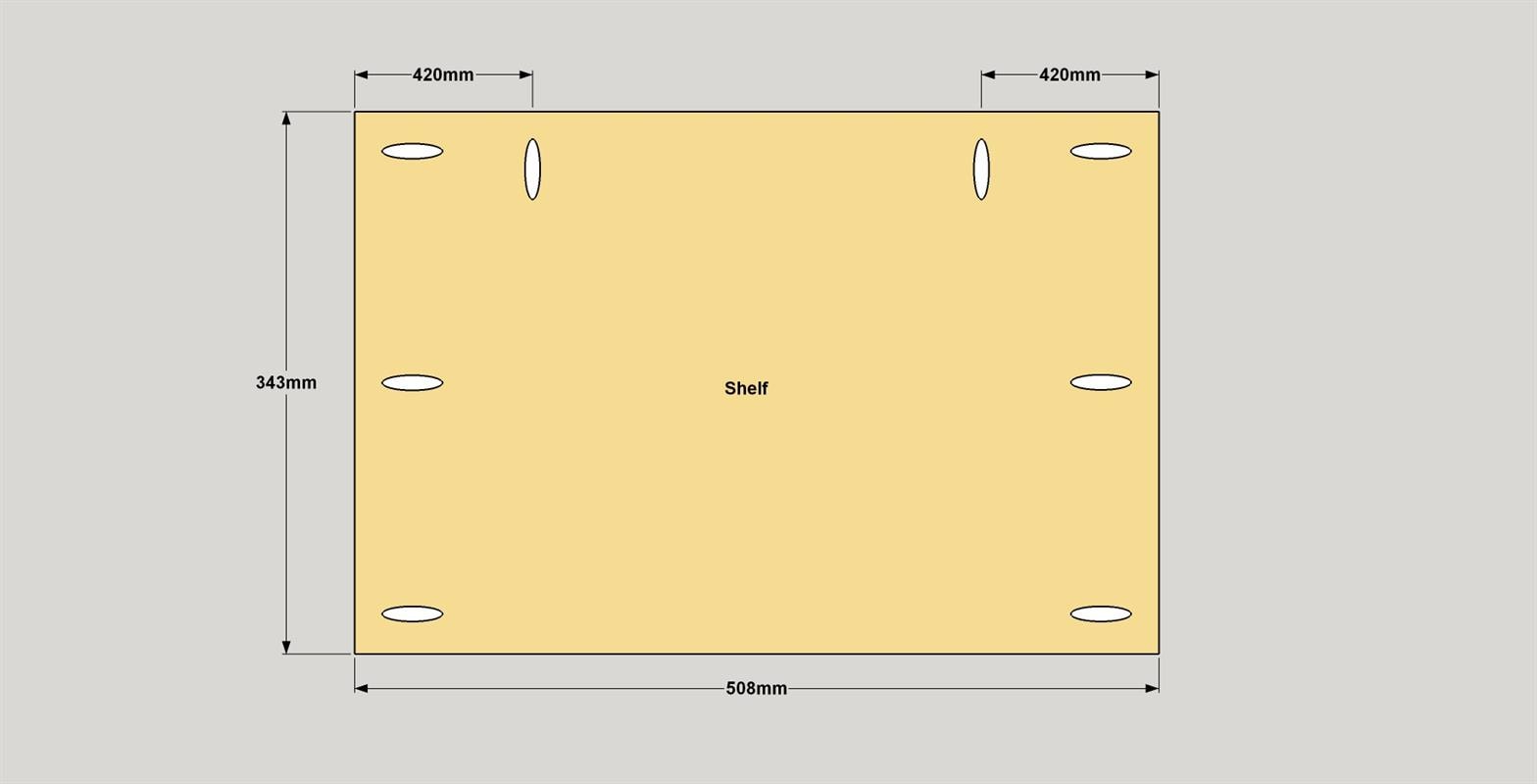

Make the Shelves

Next, it’s time to add a set of shelves that fit between the Front Panel and Back Panel. Cut four Shelves to size from 19mm plywood, as shown in the cutting diagram. Then drill pocket holes in all four Shelves as shown. Pay attention to the two pocket holes along the back edge. They need to be within 115mm of the Shelf ends so that the screws will hit the Inside Frames when you install the Shelves. Sand the pieces as needed.

-

Install the Shelves

Position the Shelves at the locations shown, and then secure them to the Front, Back, and Inside Frames using 32mm coarse-thread pocket-hole screws.

-

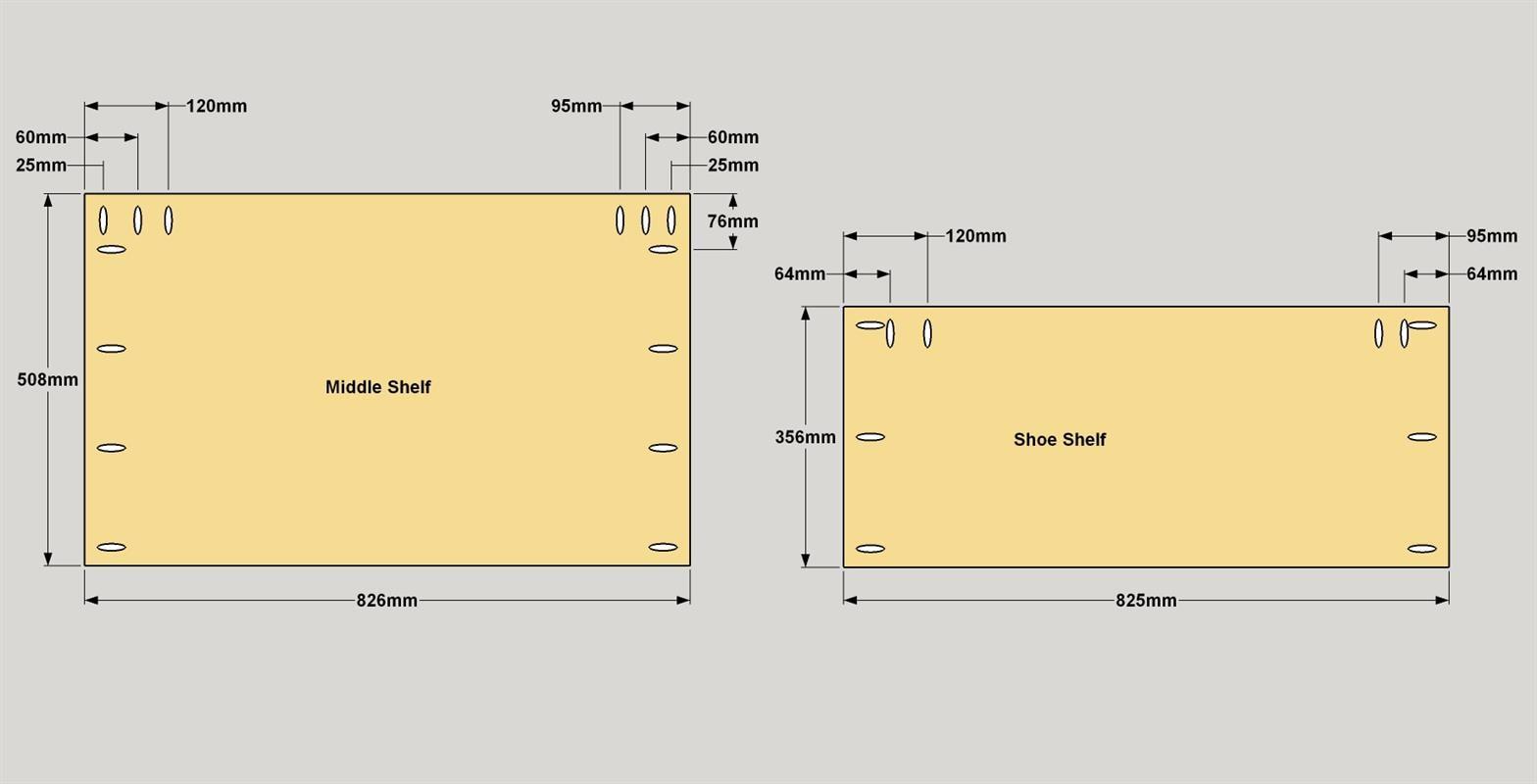

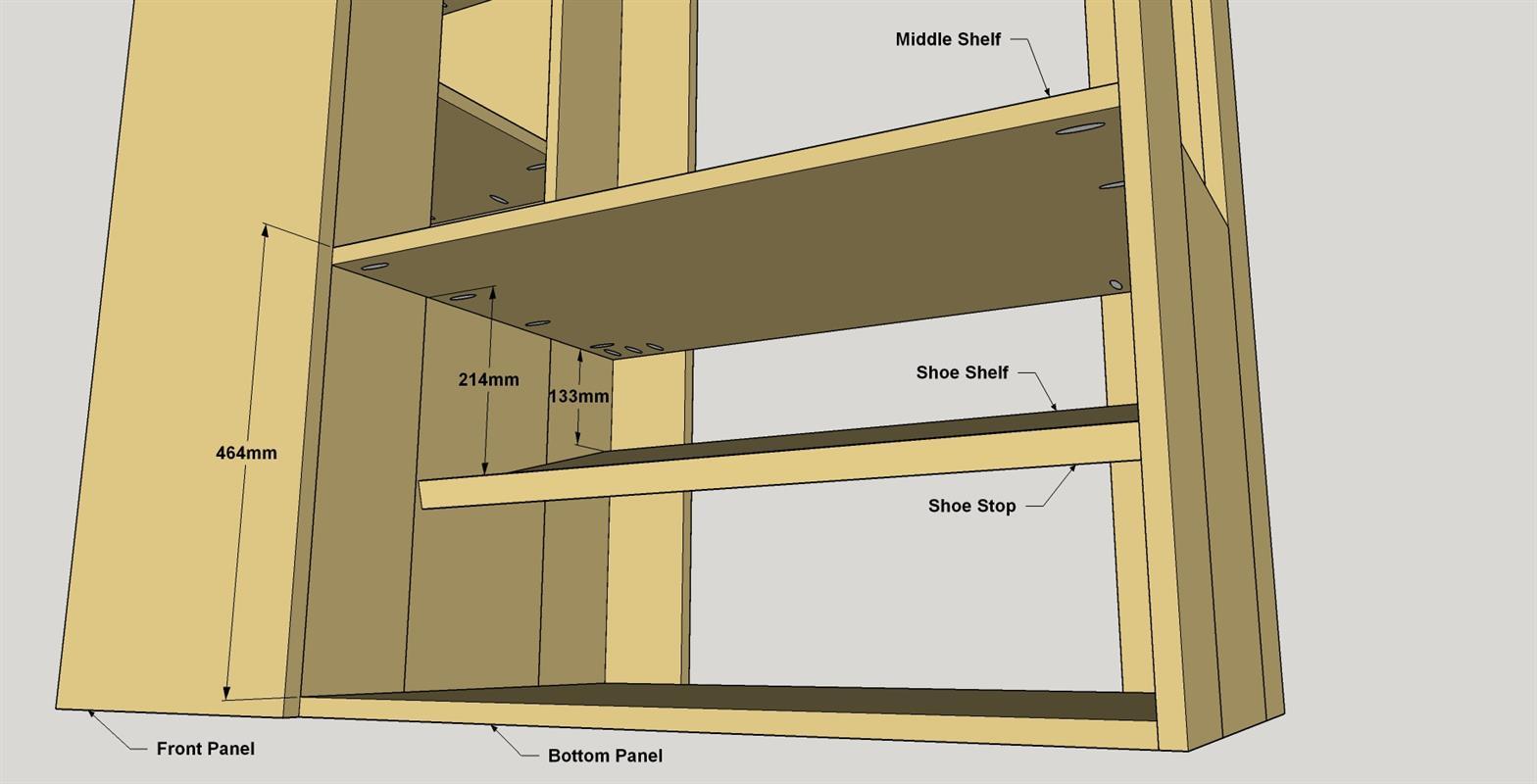

Make the Remaining Shelves

The last additions to the freestanding closet are another set of Shelves: The Middle Shelf and Shoe Shelf. Cut these Shelves to size from 19mm plywood, as shown in the cutting diagram. Drill pocket holes in the Shelves where shown. Pay attention to the location of the pocket holes along the rear edge of each shelf. Also cut one Shoe Stop from 6x32mm Pine lattice, as shown in the cutting diagram. Glue and nail the Shoe Stop to the front edge of the Shoe Shelf so it sticks up above the surface. This will prevent shoes from sliding off the shelf, which gets installed at an angle. Sand the pieces as needed.

-

Install the Remaining Shelves

Attach the Middle Shelf at the location shown using 32mm coarse-thread pocket-hole screws. Then position the Shoe shelf (with the Short Stop pointing upward) and attach it as well.

-

Paint and Add Optional Edging

With the assembly complete, you can decide how you want to finish your freestanding closet. We chose to paint the flat surfaces, and leave the edges natural. This provides an interesting look, but the exposed plywood edges don’t look as good as the solid-wood edges. If you want to cover them up, just cut pieces of screen molding, and then glue and nail them to these plywood edges. We applied it to the edges of the Front and Back Panel, the Top and Bottom, the four Shelves, and the exposed edges of the Middle and Shoe Shelves.

-

Add a Hanging Rod and Casters

Finally, cut a Closet Rod to length from a 32mm dowel, as shown in the cutting diagram. Then you can install the Rod using closet rod hardware, and attach a set of casters. We chose big industrial-style locking casters for our freestanding closet. We also added a mirror to the Front Panel.