Finishing and Supply Cabinet

By Knotty Dog WoodshopBig step to a functional workshop is organization! This simple finishing and supply cabinet can be built in a weekend. This holds quart sized paint cans, spray paints, extra glue bottles and other supplies that are frequently used. Check out our Youtube Video in the Extras Tab!

Directions

-

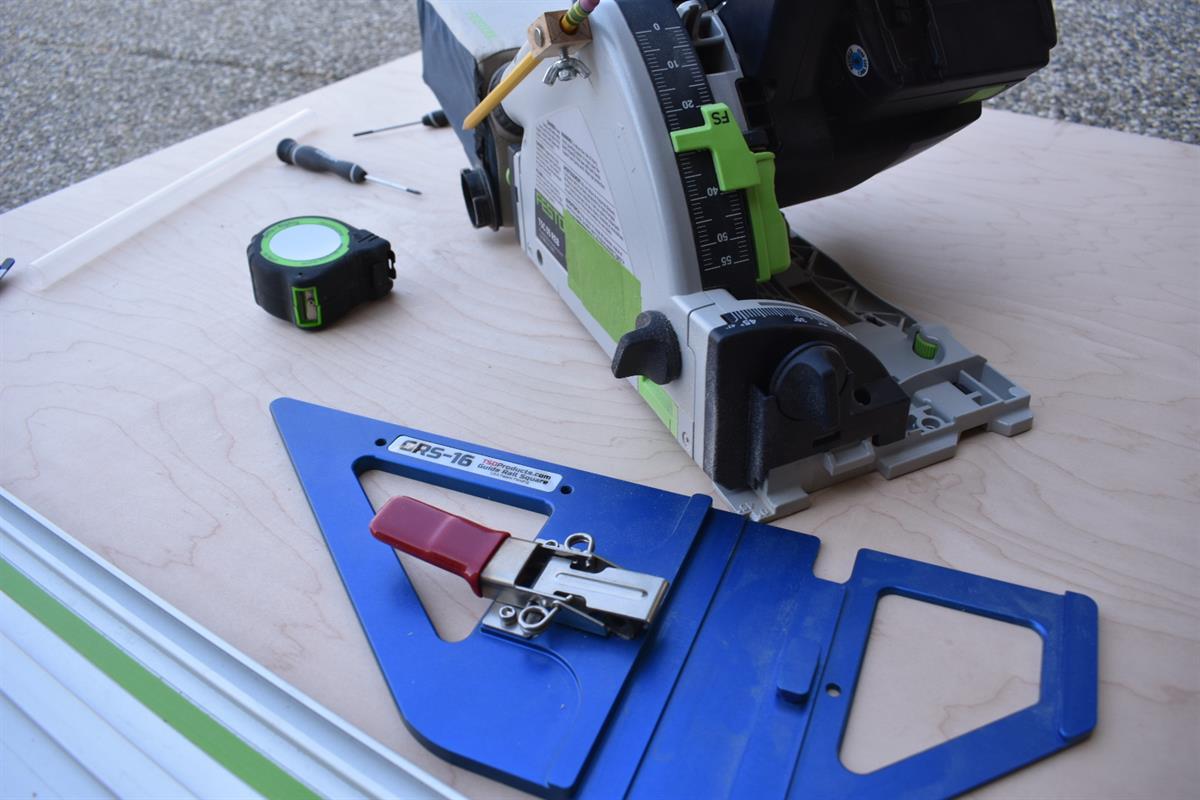

Break Down the Plywood

The safest way to breakdown plywood is on the ground. I use a track saw, but a circular saw and a reliable straight edge works just as well.

-

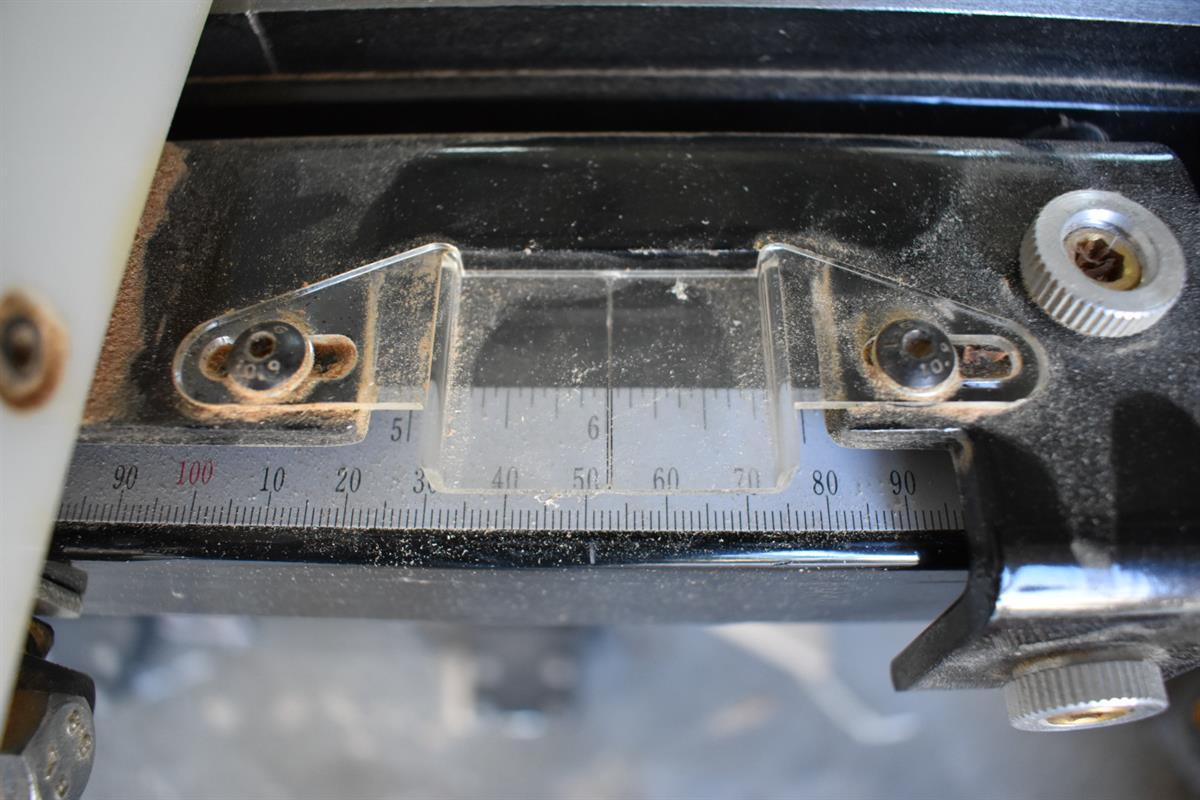

Layout Lines

One way to get the most out of a plywood sheet is to mark your layout lines. Cut the pieces oversized and when it is more manageable to work with, rip it on the table saw for a final width.

-

Rough Cuts

Cabinet Sides and Top and Bottom: Rip the plywood at (1)13" wide by 96" long. They will be ripped on the table saw for exact width later.

Shelves: Rip (4) 51/2" by 96" long pieces. These will be ripped for the final width later as well.

-

Rip Cabinet Sides to Width

On the table saw rip the the 13" by 96" board to (2) 6" by 96"boards.

-

Rip for the Shelves

With the help of the feather board rip the (4) 5 1/2" x 96 " boards to (4) 5 1/4" by 96"boards.

-

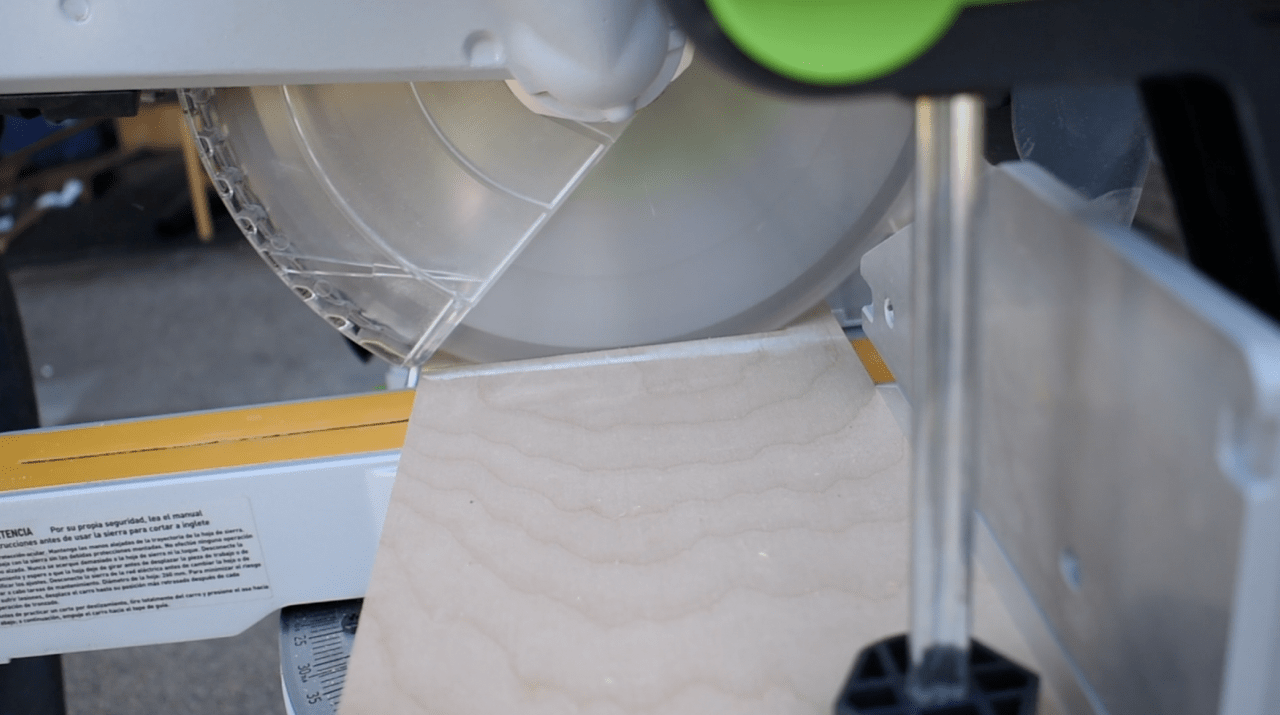

Miter saw

For the Cabinet crosscut (2) 6" wide by 66" long and (2) 6" wide by 30" long . For the shelves crosscut (12) 5 1/4" wide by 30" long. *If you do adjustable shelves, cut two shelves later to fit*. NOTE: You won't use all 12 for the shelves. Some will be used as a nailer to hang the cabinet up on the wall.

-

*Optional Edge Band*

This is an extra step but edge banding gives the shelves a very clean and professional look.

-

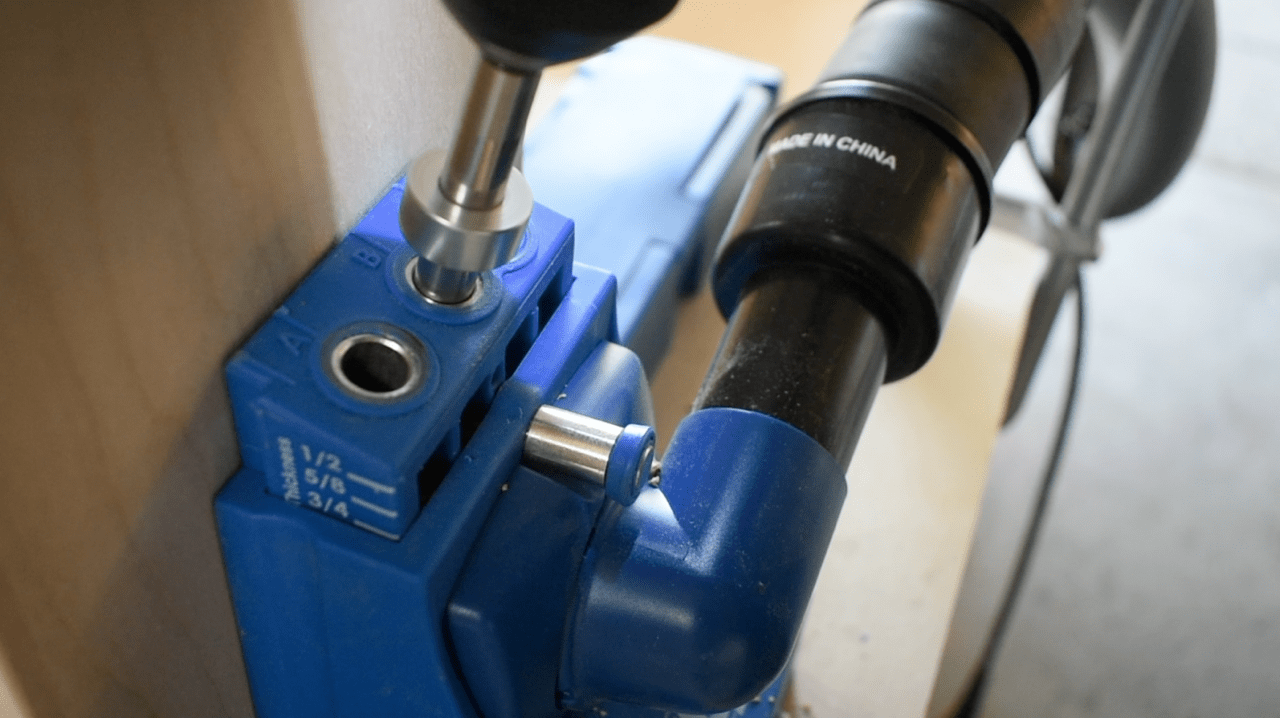

Pocket Hole

On 10 of the 5 1/4" by 30" pieces drill pocket holes to screw into the cabinet sides. Set aside the two shelves that will be adjustable, they do not need pocket holes drilled into them.

-

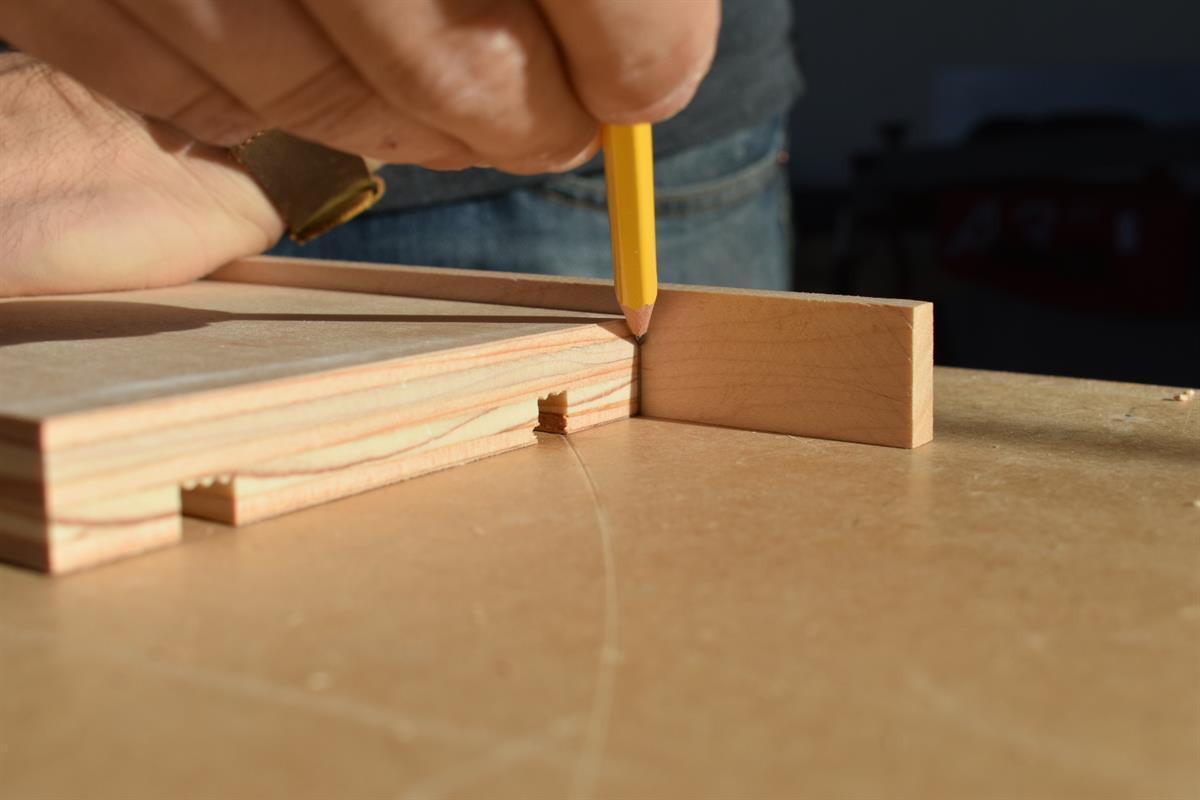

Spacer for shelves

I used a spacer a little taller then a quart can (5 1/4") to begin my shelf layouts. Depending on what you will store in the cabinet, adjust the height of the shelves to your needs. I used 7 shelves screwed to the cabinet sides, 2 adjustable shelves and 3 shelves where perpendicular to the 7 fixed shelves, spaced throughout the cabinet. The 3 perpendicular shelves act as a nailer for the cabinet to get screwed to the wall into studs.

-

Adjustable Shelves

After the last shelf is screwed to the cabinet side. Use the adjustable shelf jig for the adjustable shelves.

-

Groove for the Adjustable Shelves

With the table saw or router, create a groove where the adjustable shelf pins will rest on the underside of the shelf. This will act as a catch, so the shelf will not tip over.

-

Adjustable Shelf Lip

Add a thin piece of scrap wood you have laying around the shop to use as a catch so nothing rolls off. Attach the wood trim that is slightly taller then the 3/4" plywood. This is optional.

-

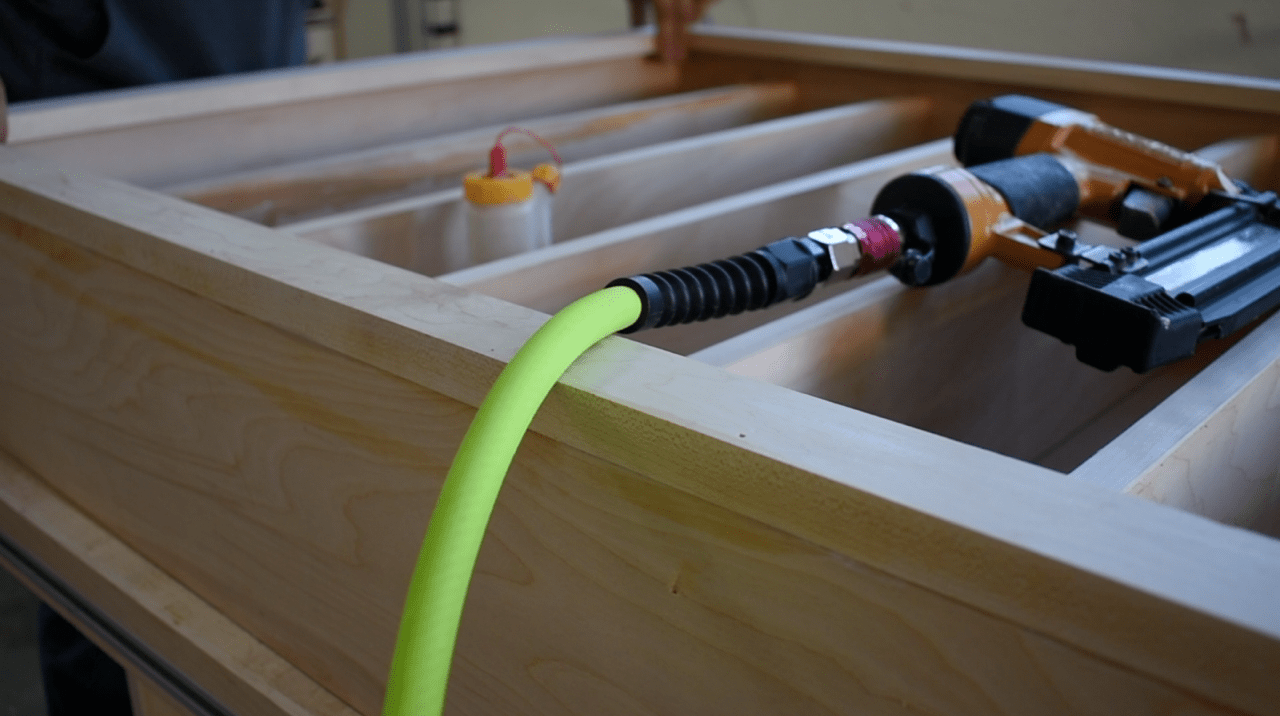

Face Frame

For a solid wood face frame cut (2) 3/4" thick by 1 1/2" wide by 66" long pieces and attach to the long cabinet sides with glue and brad nails. The rails, can be cut to size with another 3/4" by 1 1/2" solid wood stock.

-

*Optional* Door

I like to have my cabinet doors covered so there isn't any unwanted dust laying around my shop. I added a MDF door, that I cut to size.