Entry Table

By Carolina MissThis is a quick easy way to add low key legs to a wooden slab to create a one of a kind entry table. This is a build that anyone can do using standard 2×4 common boards from your local box store, your Kreg pocket hole system, and a handful of Kreg screws.

Directions

-

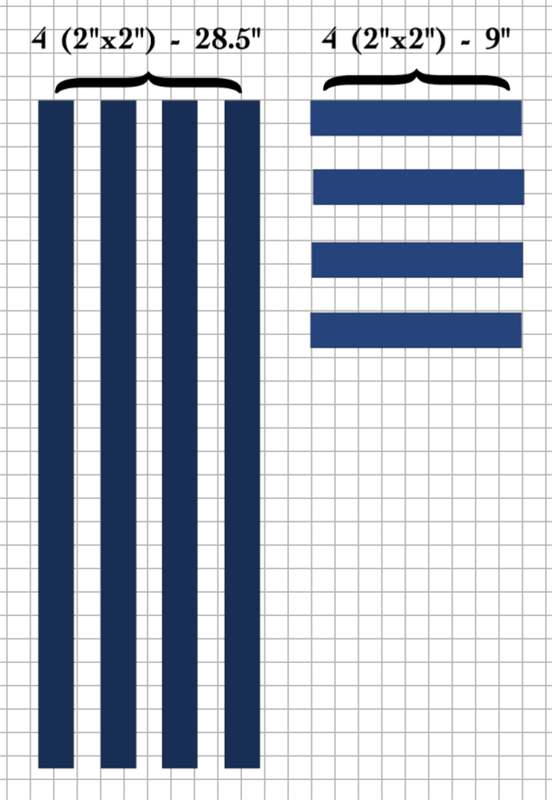

Cut Legs

Cut your (4) 2x4 legs to 28.5 inches. You will need to ensure they are perfectly square cuts for seamless jointing later. Picture for reference on how to cut your boards square. Here we used Kregs Precision Miter Guage.

-

Cut Leg Braces

Here you will cut (4) 2x4 braces at 9 inches each. Again make sure your cuts are perfectly square for seamless jointing with the legs.

-

Adjust Your Kreg Jig Pocket System

You will set your board thickness on your Pocket Hole system to your board thickness. Ours here was 1.25 inches thick.

-

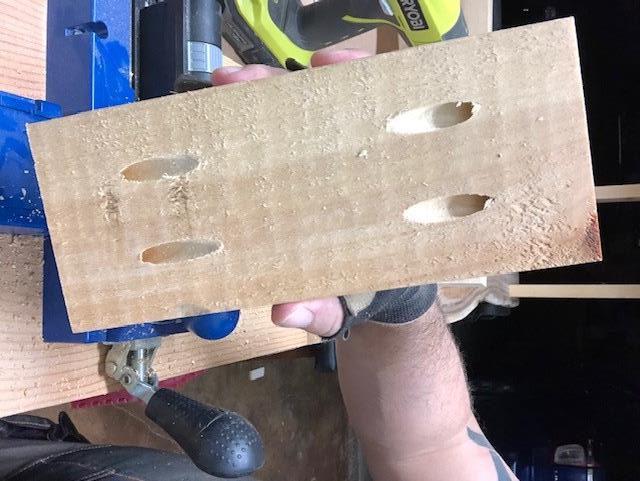

Drill Your Holes

Then drill 2 holes on each side of your 9 inch brace. Each brace should have 4 holes.

-

Verify Your Holes are Centered

Here your holes should be as close to even as possible. A great tip here is to mark the center of your board and then center that between the drill guides.

-

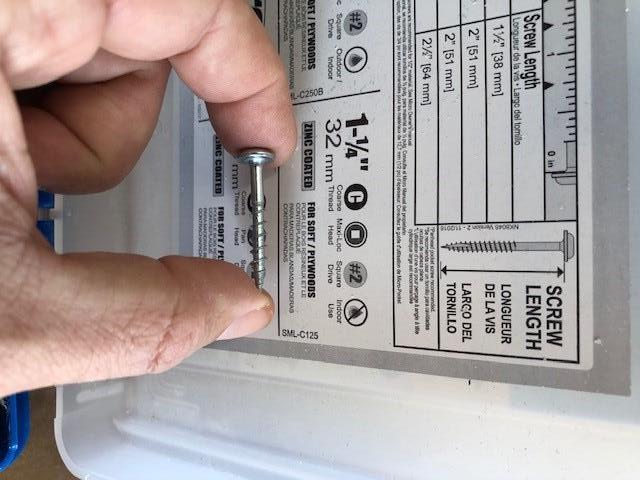

Get Your Screws

Since ours was 1.25 inches wide, that is the length of screws we used. Kreg has a great system inside the lid of their screw case as seen here.

-

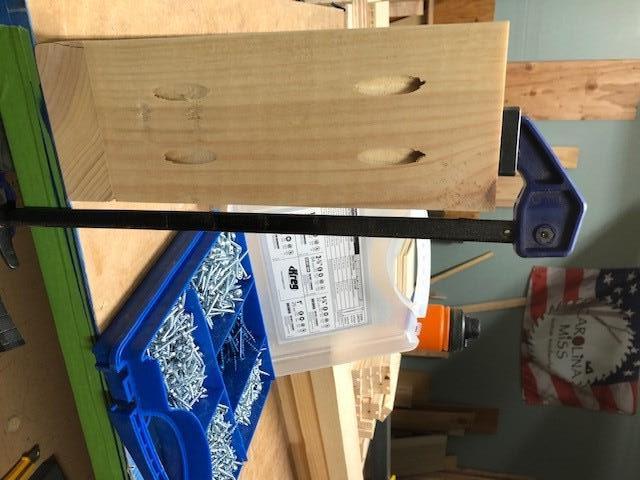

Clamp Your Brace to the Leg

Now you are ready for assembly. Clamp your brace to your leg. Ensure your brace sits flush with all 3 edges of the leg as shown.

-

Verify Squareness

Here we use a speed square to verify we are completely square. Then add in your first 2 Kreg Screws. Ensuring you are square here will save you headaches later.

-

Add in Remaining Screws

Using the previous method of clamping and squaring, add in the remaining screws.

-

Sand all Pieces

Here is where you sand your pieces to your desired smoothness.

-

Attach Legs to Table Top

We used (4) 2" screws in each leg in a staggered pattern. The staggered pattern allows for weight distribution.

-

Countersink Holes for Table Top

During this step, you can either use bottom head screws or countersunk screws. If you wish to use countsunk screws, you will need a tool as shown. It is a universal countersink. Countersink the holes just deep enough to allow the head of the screw to sit flush.