Built-In Mudroom Bench

By Rogue EngineerWhen we designed our house one thing we knew we had to have was a mudroom bench and lockers for all of our daily stuff like jackets, back packs, shoes, etc. In this post I am going to go over the process of building and installing our custom built-in mudroom bench with reclaimed slab wood top.

Directions

-

Overview

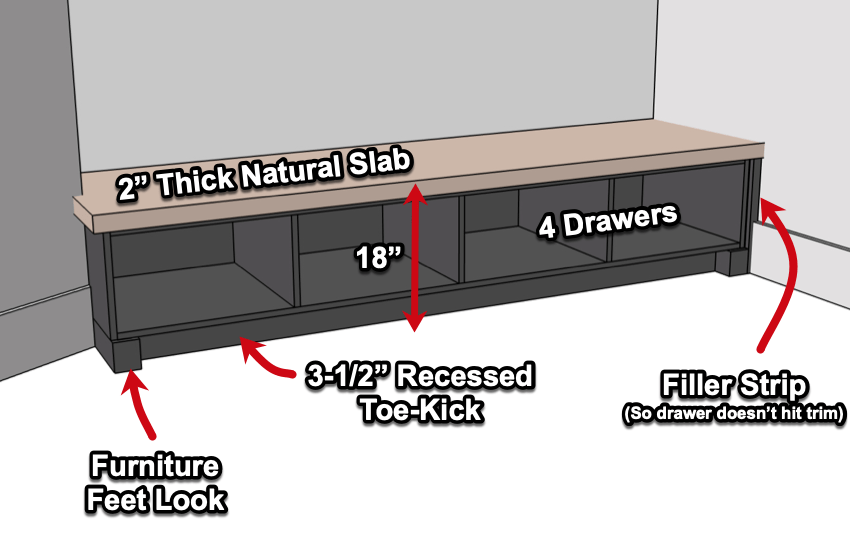

Our mudroom bench needed to be built into this 88 inch nook. One side was up against the wall completely so I knew we would need to add a filler strip so that the drawer would be able to pull out. We also wanted recessed toe-kick since we plan on adding lockers above it. The base will get black paint and the top will be a 2 inch thick natural wood top. While this piece will be built-in I still wanted to make it look like a piece of furniture so we will be adding feet to the ends.

-

The Base

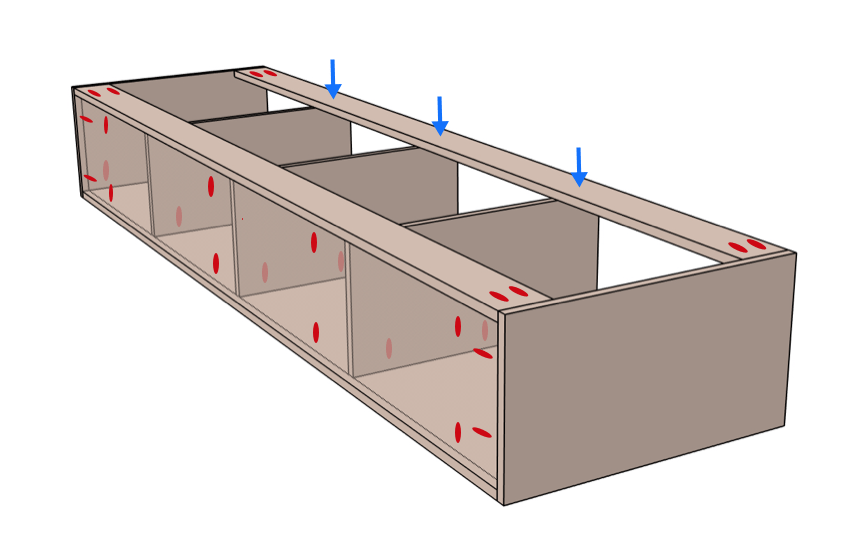

The construction of the base is very similar to a cabinet. It is made from 3/4" plywood and it will be separate from the platform (toe kick).

The width of your unit and how many dividers you have will be determined by your space and needs. However, the bench height is fairly standard at 18 inches, so that will determine the height of the carcass.

-

Building the Carcass

The height of the bench should be 18 inches so to get the height of the carcass you’ll need to subtract the top and the 3-1/2″ platform.

Dividers are equally spaced and the carcass is assembled with 1-1/4″ pocket screws. I found the Kreg R3 Jr. pocket hole jig to be the easiest to use when drill pocket holes in larger pieces of plywood like this.

-

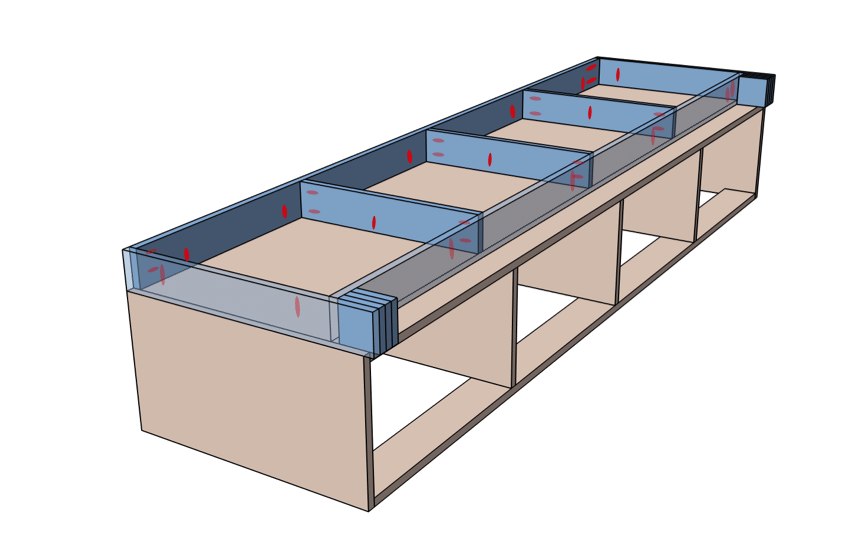

The Platform

The platform is assembled and attached to the bottom of the carcass with 1-1/4″ pocket screws. It looks something like this, with the feet just being glued up blocks of plywood that will get wood filler and sanded smooth for paint.

-

Drawer Boxes & Doors

The drawer boxes were assembled by a local cabinet shop that can do it better and cheaper than I but I did make the drawer fronts myself. To learn more about that process check out the extras tab for the link. And if you need to know how to make a simple drawer box a link to that tutorial will be in the extras tab as well.

-

Prepping for Paint

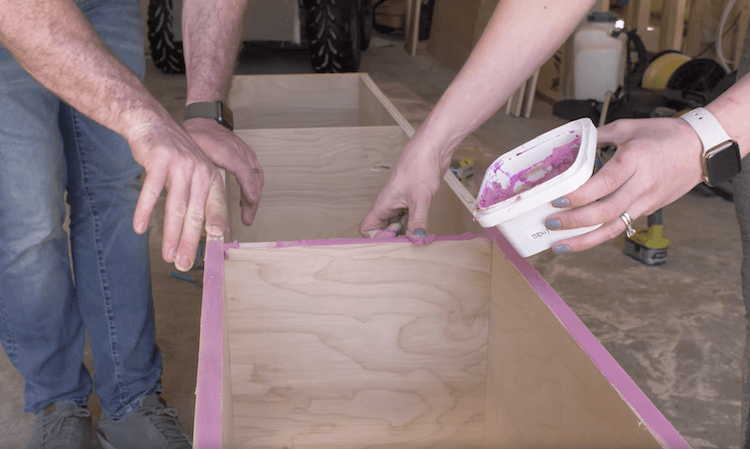

To get ready for paint we first needed to fill any joints and imperfections. We did so with Plastic Wood-X which is a wood filler with dry time indicator. Meaning the color changes from pink to tan when it is dry, so you know when you can begin sanding.

Another thing we did was to coat than plywood edges with wood filler as well. The other option is iron-on edge banding but we thought that this would be a more durable option.

-

Painting

Since this is bare wood, the first thing is to prime the surfaces that will get painted. Then, we followed up with two coats of BEHR® Urethane Alkyd Satin Enamel in the color Cracked Pepper. This paint is specifically designed with the durability needed for trim and cabinetry. Typical latex paint is not recommended.

-

The Top

For the top, we wanted something special, so we headed to Live Edge Detroit where we found two locally salvaged Siberian Elm slabs that was calling our name. Since the slabs had a live edge on then we needed to cut a straight edge. We did so with the Kreg Adaptive Cutting System Saw. I have always wanted a track saw and this thing is as awesome as I had always hoped it would be. It is super simple to use and much safer than a table saw. Now we can start to get an idea of how this top is going to look.

-

Flatting the Slabs

When it came to flattening the slabs I ended up having to run half of the top at a time due to the capacity of my planer. Each piece was put on a sled and any gaps were shimmed so it wouldn’t compress as it went through the planer. This process work okay but not perfectly. Next time I would use a router, flattening jig and surfacing bit.

-

The Glue Up

For this glue up I wanted to make sure the alignment was as close to perfect as possible so I put some biscuits in to reduce the amount of planing/sanding required to smooth out the joint.

Then, with a high quality wood glue and some serious clamping, we were able to pull this top together.

-

Blending the Joint

To blend the joint I started out with a hand planer to plane down and high spots. Anything that couldn’t get done with the planed got sanded down with a belt sander and finished off with a random orbital sander.

-

Epoxy Fill

We did have a crack in one board so we filled that with a two-part epoxy mixed with a drop of black acrylic paint for color. Once it had hardened we hit it will a sander to level it out.

-

Preparing for Install

Before we could make our final cuts to the top we needed to get a better idea of exactly how it needed to be cut. So I went ahead and started to install the base to make it easier. The baseboard trim has to get removed from the wall where the unit is going to go. I did so with an oscillating tool and a pry bar.

-

Template Tricky Corners

Then I used a scrap piece of 1/4″ plywood to create template for the tricky corner on the left side.

-

Final Cuts for Top

Then I came back with the track saw to make the final cuts and a Japanese pull saw to finish off the inside corners.

-

Sanding Top

I then followed up those cuts with the fine grit sandpaper and eased any exposed edges.

-

Oiling the Top

Lately we had started using oil more often as a finish and have really been loving it. This top got several coats of Tung oil and the natural beauty of the wood really came to life when the oil hit it.

-

Installation

We started off by locating the wall studs and securing the bench to the studs with 3″ wood screws. During this process we made sure that the bench stayed level and shimmed as necessary to get it there.

-

Filler Strip

Then, since the base was made to fit within the trim we needed to install the filler strip. This is an L-shaped piece that was made wider than required and ripped down to the final width on install and secured from inside the cabinet.

-

Install Top

To install the top we set it in place, checked for level, shimmed from below as necessary and secured it from within the base with wood screws.

-

Install Drawers and Slides

The drawers were made by a local woodworking shop Elliott Woodworking who can do it cheaper and better than I. Plus they offer to notch the drawer and pre-install Blum under-mount slides for cheap! All I had to do was give them the width of the opening, height and depth of the box, and when they came in I just screw the slides in places, flush with the face of the base and slide the drawers in.

-

Drawer Front Installation

The back of the drawer fronts needed to be filled so that drawer handles that get installed in the future wont cause the panel to suck in. So I used some Rapid Fuse fast curing adhesive to bond 1/4″ plywood on the back.

I then applied 2 big dollops of hot glue to the back and temporarily glued them to the drawer boxes to make sure the placement was correct.

Once I was happy with the layout I secured them from within the drawer box with 1-1/4″ wood screws.

-

Finishing

To finish it off we caulked the cabinet into the wall and trim with DAP’s Alex Plus. After 30 minutes we could follow-up with touch up paint to match the walls.