Selecting pressure-treated lumber for outdoor projects is a lot like selecting other wood. You’ll want to make sure you get all he boards you need plus a few extras. You should take extra time to go through the available boards and pick out the best ones. But there are a few other things you’ll want to pay attention to, as well.

Select the right size

- Treated lumber is sold in common dimensional thicknesses and width, such as 2×4, 2×6, 4×4, etc.

- Some treated boards are available in long lengths—10′, 12′, even up to 16’—for building larger projects, such as decks.

- Decking boards are often sold in a thickness that may seem unfamiliar: 5/4. This refers to how many quarters of an inch thick the board was when first milled. So, a 5/4 deck board was originally milled “five quarters of an inch,” or 1¼”, thick. Finished thickness is usually 1″.

Know the intended use

Most of us pay little attention as we shop for wood to the tag on the end of the board—except maybe to make sure it’s pointing the right way for the cashier to scan. With pressure-treated lumber, though, that tag has some information you’ll want to pay attention to—namely whether the wood is meant for use in contact with the ground, or it’s meant for above-ground use.

“Ground Contact” means these boards can be placed directly on or in the ground, or used in places where they will be frequently damp or difficult to access—such as deck joists. To get this rating, the boards are treated with a more-concentrated mixture of the preservative chemicals.

“Above Ground” means these boards should only be used in places where they won’t contact the ground directly, and where they are able to dry out easily and quickly. Decking, railings, and balusters, are usually rated for above-ground use, as are “1-by” boards, such as 1x4s and 1x6s.

Boards rated for ground contact can be used in above-ground applications, but above-ground boards should not be used on or below ground, in places where they will remain wet for extended periods, or where premature rot could compromise the strength of the structure.

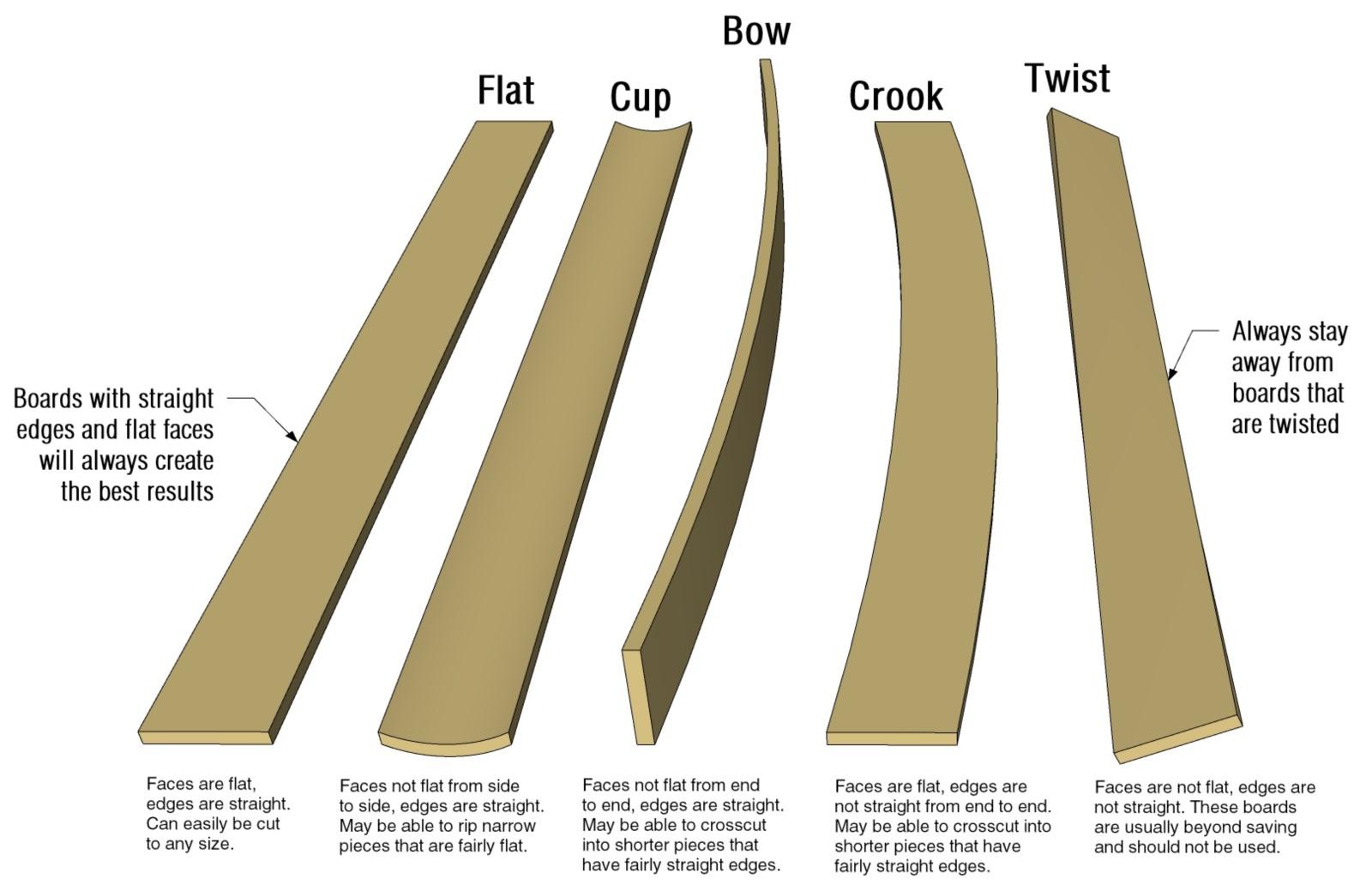

Look for Defects

When a tree is cut down, the wood within contains quite a bit of moisture. After the tree is cut into boards, they begin to dry out. And, as the wood dries, forces in the wood can cause it to shrink, warp, and bow. Because treated wood gets completely saturated with liquid during the treating process, it tends to suffer more of these problems as it dries.

To make sure you get the best results on your outdoor projects, take some time to go through the stack and examine the boards while you check them for these common defects. You may be able to work around some defects if you have to, but others are too challenging to deal with.