Learn about the advantages for outdoor projects

Pressure-treated wood is made for use outside, where exposure to the elements can quickly rot untreated wood and where damage from insects (like termites) is common. The preservatives used to pressure-treat wood give it resistance to these things to make it last much longer outdoors.

Rot/Decay

Microbes, fungus, and other elements can cause wood fibers to deteriorate, which shows up as rot and gaps in the wood. Preservatives in pressure-treated wood resist these elements.

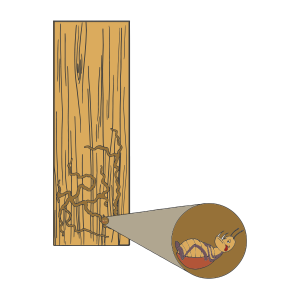

Insects/Termites

Insects, especially termites, eat wood fibers and tunnel into the wood to lay eggs. Preservatives in pressure-treated wood make it unattractive to insects.

How it works

During the treating process, the preservatives are forced deep into the wood, where they bond with the fibers to give it long-term protection.

Most of the time, a wood called Southern Yellow Pine is used to create pressure-treated wood. Southern Yellow Pine grows quickly, offers good strength for building structures, and has wood fibers that readily absorb preservative chemicals during the pressure-treating process.

How it’s made

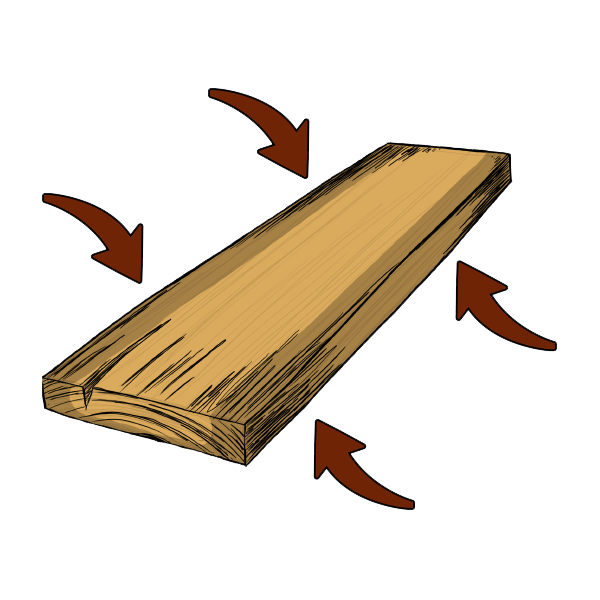

Pressure-treated wood gets its name from the process used to create it. The wood, which has already been cut into boards, is treated by forcing the preservative chemicals into the wood fibers under pressure.

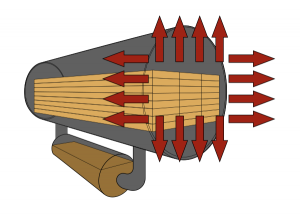

Step One

Boards get placed into a sealed tank. Then air is removed from the tank using a vacuum. This pulls air out of the chamber, and out of the wood fibers.

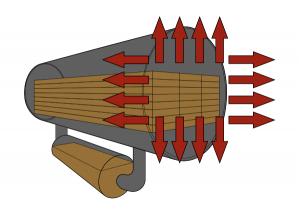

Step Two

Liquid containing preservatives is pumped in, then the tank is filled with positive pressure to force the liquid deep into the wood.

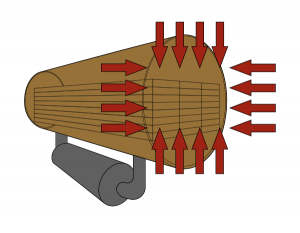

Step Three

Vacuum pressure is used again to pull excess liquid from the tank and from the wood. The chemicals stay bonded to the wood fibers. This process removes most of the liquid from the wood, but the boards will remain quite moist.