Woodworking enthusiasts are always on the lookout for tools that can enhance precision and efficiency in their projects. Track saws have gained popularity for their ability to deliver straight and accurate cuts with ease. Check out our article on the 7 top track saw uses.

However, many people wonder if it’s possible to transform their regular circular saws into track saws for similar benefits. In this comprehensive guide, we’ll explore track saws, examine the components of both track saws and circular saws, and take a look at converting a regular circular saw into a track saw.

Limitations of a circular saw

While circular saws are invaluable for many tasks, their fundamental limits become apparent when you need precise cuts. Without a guided track system, achieving perfectly straight cuts with a circular saw can be challenging to say the least, leading to inaccuracies and uneven edges, especially when cutting large sheets of material without any kind of guide in place.

Understanding Track Saws and Their Advantages

Track saws are specialized tools designed for making precise and straight cuts in various materials, including wood, plywood, and MDF. Unlike traditional circular saws, track saws feature a guided track system that ensures consistent cuts along predetermined paths. This setup offers several advantages, including improved accuracy, reduced splintering, and enhanced safety.

Track saws have revolutionized woodworking, offering precision, accuracy, and versatility that traditional circular saws often struggle to achieve. In this section, we will delve into what track saws are, how they differ from conventional circular saws, and explore the numerous advantages they offer to woodworkers of all skill levels.

What is a track saw?

A track saw, also known as a plunge-cut saw, is a specialized power tool designed to make straight and precise cuts in various materials, including wood, plywood, and composite boards. Unlike traditional circular saws, track saws feature a guided track system that ensures consistent and accurate cuts with minimal effort and skill required from the operator.

Distinguishing features of track saws

Track saws are characterized by several key features that set them apart from traditional circular saws:

Guided cutting

The track provides a stable and precise cutting path, making it easy to get straight cuts with ease and confidence.

Plunge-cut capability

Track saws can make plunge cuts in the middle of a workpiece without needing to pre-drill or create starter holes.

Dust collection

Many track saw models come equipped with dust collection ports or attachments that help minimize dust and debris during cutting, resulting in cleaner workspaces and improved visibility.

Versatility

Track saws can be used for a wide range of cutting tasks, including rip cuts, crosscuts, bevel cuts, and more, making them indispensable tools for woodworking projects of all sizes and complexities.

Advantages of track saws

Track saws offer several advantages over traditional circular saws, including:

Enhanced accuracy

The guided track system ensures that cuts are precise and straight.

Reduced tear-out

The anti-splinter strips on the track minimize tear-out and splintering, resulting in cleaner and more professional-looking cuts.

Improved safety

Plunge-cut capability and built-in safety features help reduce the risk of kickback and blade binding, enhancing overall safety for the operator.

Time savings

With their ability to make quick and accurate cuts, track saws help woodworkers complete projects more efficiently, reducing overall production time and increasing productivity.

Versatility

From breaking down large sheet goods to trimming doors and cutting trim pieces, track saws excel in a variety of cutting tasks, offering unmatched versatility in the workshop.

Components of a track saw system

A typical track saw system comprises several key components:

Track or guide rail

The track serves as a straight edge guide for the circular saw, providing a stable cutting path along the material being cut.

Saw base or shoe

The saw base, also known as the shoe, attaches to the track and glides along its length.

Anti-splinter strips

Many track saws feature anti-splinter strips or splinter guards, which help minimize tear-out and splintering along the cut line, resulting in cleaner cuts.

Together, these components work in tandem to facilitate accurate and controlled cutting, making track saws popular choices among woodworkers seeking precision and efficiency.

Can you convert a circular saw into a track saw?

Converting a regular circular saw into a track saw is a common DIY project with woodworking enthusiasts seeking to get more utility out of their tools. While it’s technically possible to create a makeshift track system for a circular saw, it’s important to know several challenges and limitations.

One of the main challenges is ensuring the circular saw remains securely attached to the track and maintains proper alignment throughout the cutting process. DIY track systems often lack the precision and stability of commercially available track saws, leading to potential inaccuracies and safety concerns.

Another consideration is the complexity of designing and constructing a functional track system that accommodates different circular saw models and blade sizes. Achieving smooth and consistent cuts with a DIY track saw setup requires careful planning, precise measurements, and attention to detail.

Can you add a track to a circular saw?

The short answer is yes. The more accurate answer is yes, but with a few considerations. While circular saws are not inherently designed to work with track systems, there are aftermarket options available that allow for the integration of tracks.

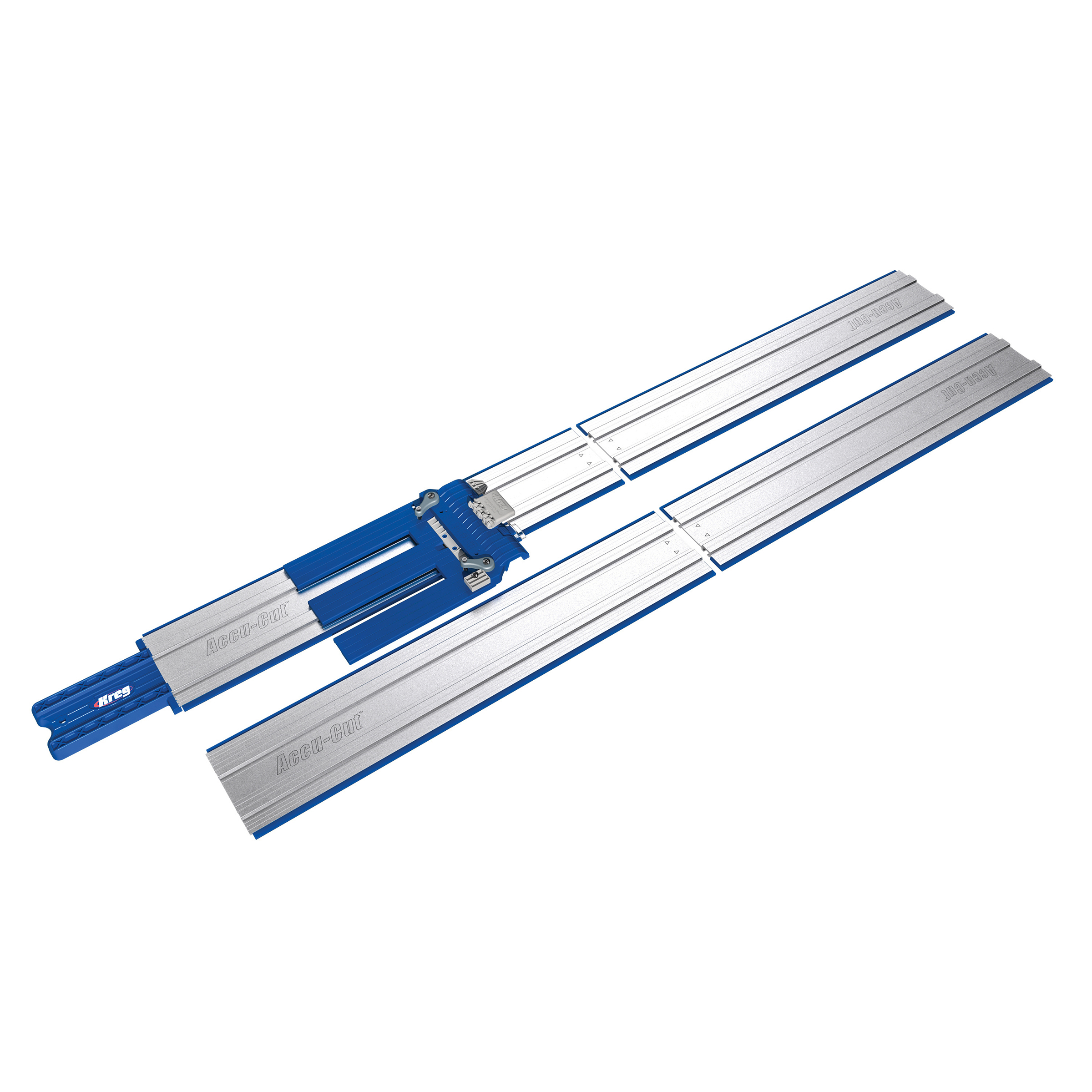

The Kreg® Accu-Cut™:

turn your circular saw into a makeshift track saw

For woodworkers who prefer not to take on extra DIY projects or who seek a more reliable and efficient solution, there are alternatives. The Kreg Accu-Cut is an excellent guide for your circular saw that can effectively replicate the capabilities of a track saw, offering numerous benefits to woodworkers of all skill levels.

Here’s why the Kreg Accu-Cut is a valuable addition to your workshop:

Precision

The Accu-Cut provides a guided cutting system that ensures precise and straight cuts every time. By attaching your circular saw to the Accu-Cut guide track, you can achieve professional-quality results without the need for expensive track saw equipment.

Versatility

With the Kreg Accu-Cut, you can make a wide range of cuts, including rip cuts, crosscuts, and angled cuts, with ease and accuracy. Whether you’re working with plywood, MDF, or solid wood, the Accu-Cut allows you to take on various woodworking projects with confidence.

Ease of use

The Accu-Cut is designed to be user-friendly, making it suitable for woodworkers of all experience levels. Its intuitive setup and operation ensure that you can achieve precise cuts quickly and efficiently, saving you time and effort in the workshop.

Portability

Unlike traditional track saw systems, which can be bulky and cumbersome to transport, the Kreg Accu-Cut is lightweight and portable. Its compact design allows you to take it to job sites or move it around your workshop with ease, giving you the flexibility to work wherever you need to.

Cost-effective solution

Investing in the Kreg Accu-Cut is a cost-effective alternative to purchasing a dedicated track saw. With its affordable price point, the Accu-Cut provides you with the precision and performance of a track saw without the hefty price tag, making it an excellent value for budget-conscious woodworkers.

Compatibility

The Kreg Accu-Cut is compatible with most circular saws on the market — both right- and left-bladed saws — making it a versatile accessory that can enhance the capabilities of your existing power tools. Whether you’re using a corded or cordless circular saw, the Accu-Cut provides a seamless and reliable cutting experience.

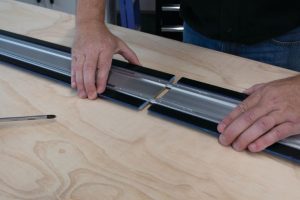

Expandable system

The Accu-Cut guide track is expandable, allowing you to connect multiple tracks for longer cuts or to accommodate larger workpieces. This versatility lets you tackle a wide range of woodworking projects, from small-scale DIY tasks to large-scale renovations and installations.