Track saws have become one of the most talked-about tools in the last few years. Whether the discussion is among professionals, woodworkers, or DIYers, there’s one question that always comes up: What can a track saw do that I can’t do with saws I already have?

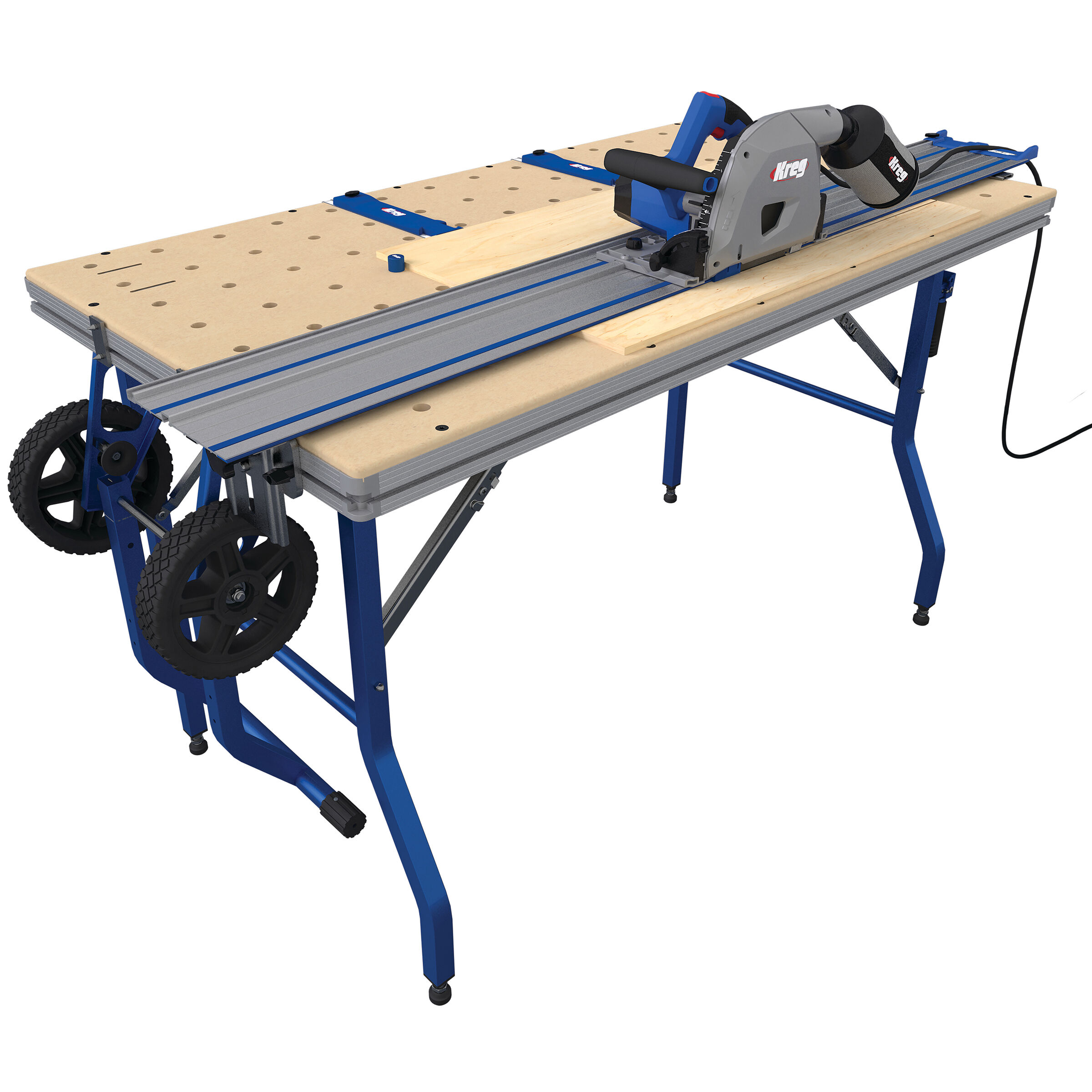

The short answer is that a track saw can do a lot. Other saws can do some of the same things. But track saws can perform a lot of cutting tasks that other saws struggle with or just can’t accomplish. That’s why we developed our Adaptive Cutting System—with the Plunge Saw + Guide Track Kit at its heart. It packs a lot of cutting capabilities in a compact package. With our Adaptive Cutting System track saw, you’ll be able to cut in more ways more precisely in more kinds of materials, and you’ll be able to do it all more efficiently.

1. Become a Master of Cutting Sheet Goods

Plywood and sheet goods are, to be blunt, a real pain to cut. It’s possible to get smooth, straight cuts with a table saw—if you have one with big support surfaces. Even then, wrestling the sheets onto the saw can be difficult and dangerous. Cutting sheets with a circular saw is a whole lot easier, but the results are seldom great. With the Plunge Saw + Guide Track Kit, though, you can cut plywood and other sheets with table-saw precision and with ease that beats a circular saw.

Fast and easy cutting

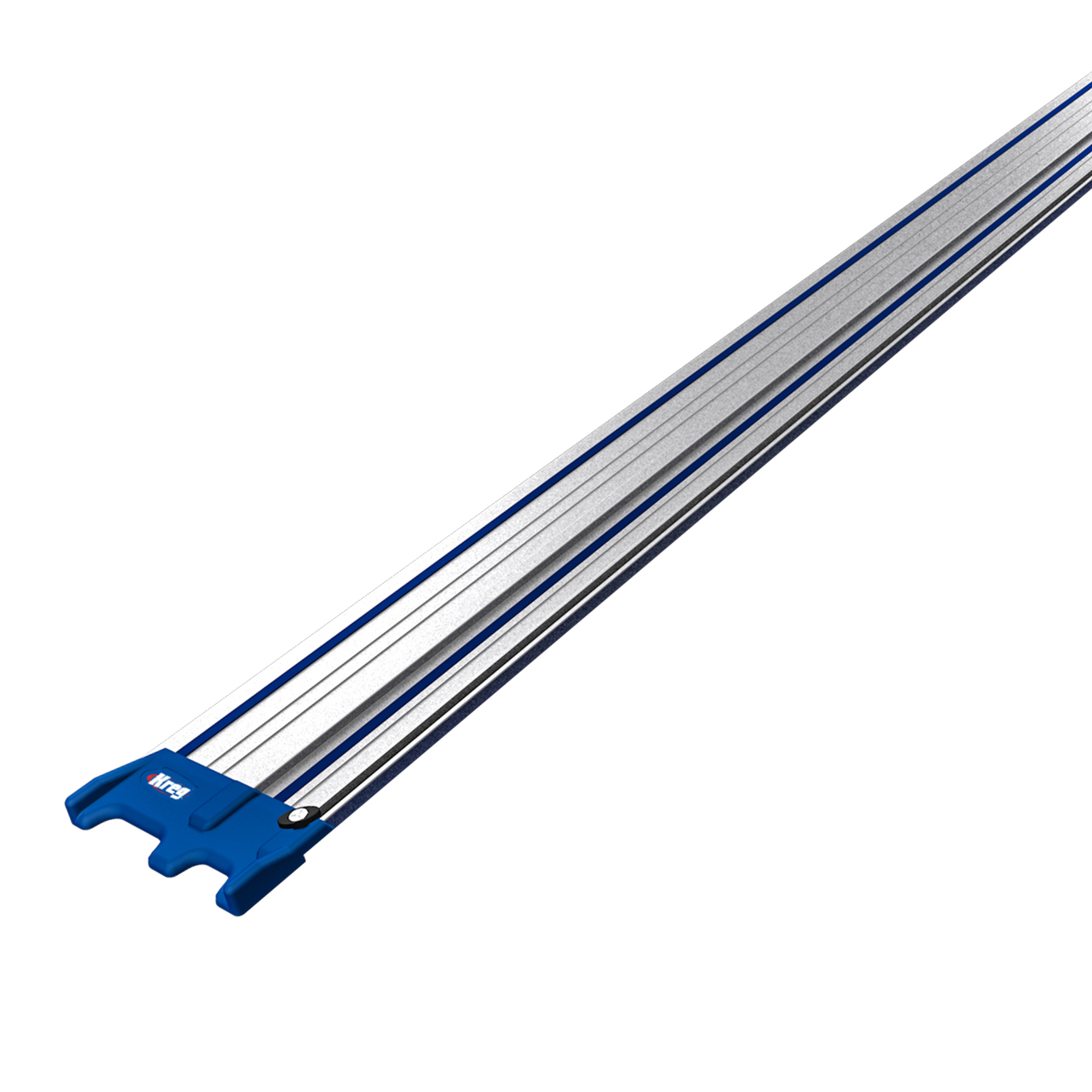

Our Plunge Saw and Guide Track make the process simple. Just mark where you want to cut. Then lay down the track with the edge right on your marks. You don’t have to worry about any offsets. Where you lay the track is exactly where you’ll cut. Then simply put the saw on the track and cut. The track guides the saw straight, so you don’t have to try to keep it on a cut line.

The Guide Track spans across full sheets, and you can connect two 62″ Guide Tracks together for full-length rip cuts.

See it in action!

Laying out and making your cuts with our Adaptive Cutting System track saw is fast and easy, since the track goes exactly where you’ll cut. So, you’ll get accurate results every time.

Effortless angled cuts

Need to cut across a piece of plywood at an angle? The track makes that simple, too. Most saw guides have to be clamped to the edges of a sheet, which restricts them to 90° cuts. With our track saw, a pair of anti-slip strips on the underside of the track hold the track in place. You don’t have to clamp it down, so you can cut across a sheet at any angle.

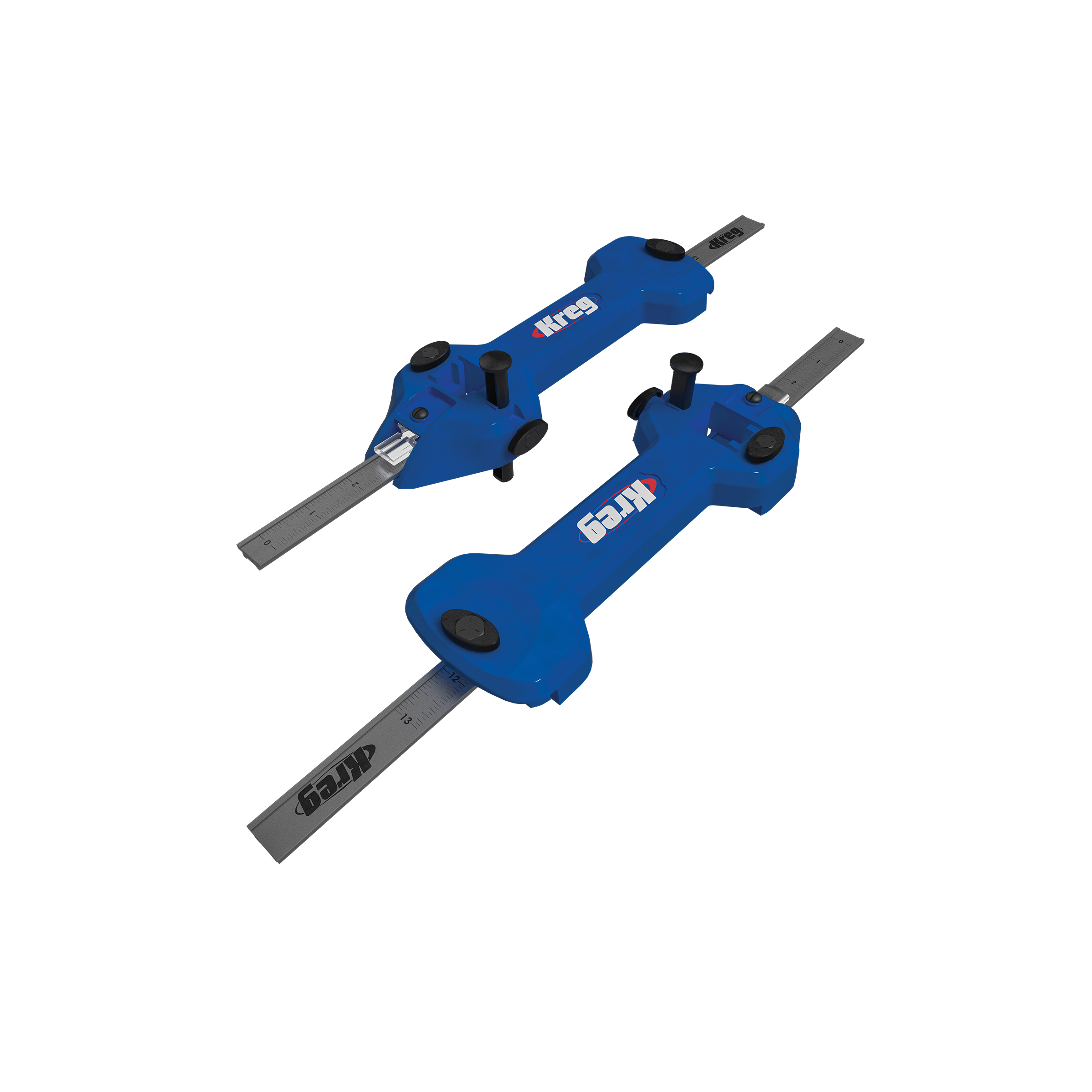

Add integrated measuring

You can make cutting sheet goods with our track saw even easier by adding Parallel Guides. They easily attach to the track when you want them. Instead of measuring and marking, just adjust the tapes to your measurement and set them with the heavy-duty locks. Then lay the track down so the measuring tapes hook over the edge, and you’re set to cut sheet goods accurately—whether you need one cut or many—much more quickly than you ever could with a circular saw.

See it in action!

Parallel guides make it even easier to set up your cuts. Just lock in the dimension you want, and you’re all set. No layout marks needed!

2. Make Laser-Straight Cuts

When you’re cutting with a circular saw, it takes skill to keep the saw moving straight. And when that cut is 4’ or 8’ long, even a little deviation from the line can add up to a big cutting error. With our Plunge Saw and Guide Track, you never have to worry.

Perfect, straight cuts

When you use a track saw, getting straight cuts is the rule instead of the exception. The way our Plunge Saw rides the Guide Track means there’s no way the blade can wander, so you get perfect cuts without even having to think about it.

Clean beveled cuts

Our track saw setup even lets you cut straight bevels, which is really tough with a circular saw. A super-accurate bevel scale makes it easy to set the correct angle, and the Guide Track gives you great saw control during the cut.

See it in action!

Whether you’re making 90° cuts or bevel cuts, our Adaptive Cutting System track saw lets you cut with confidence.

3. Get Smooth Edges and Eliminate Tearout

Straight cuts are important for accuracy, but the importance of smooth cuts can’t be overlooked. If a cut edge is rough, it won’t fit tightly. And if the faces alongside those edges are splintered and torn out, the piece will never look good, no matter how well it fits. Our track saw combats both of these problems to give you smooth cuts.

Say hello to smooth edges

To get a super smooth edge on your cuts, you need three key things: a powerful saw, a high-quality blade, and a way to keep that blade moving straight. Track saws offer all three.

Our Plunge Saw offers ample power to keep the blade from bogging down, plus a high-performance arbor and bearings to ensure that power transfers to the blade smoothly. The blade has sharp carbide teeth and anti-vibration slots that prevent chatter. Combine all that with the straight cut line produced by the track, and the result is smooth edges when cutting plywood and solid wood.

Say goodbye to tearout

Even a straight, smooth cut won’t create a good looking result if the faces of the wood are torn out and splintered alongside the cut. A track saw has built-in features to prevent it.

With our Adaptive Cutting System, the saw blade rides against a thick anti-chip strip. That keeps the fragile surface fibers from getting lifted as the saw teeth rotate up and out of the wood. On the other side of the blade, a splinter guard rides right against the face of the plywood to help prevent tearout on that side of the cut, too.

See it in action!

Our Adaptive Cutting System track saw has an anti-chip strip on the track and a splinter guard on the saw. They mean you can can be confident you’ll get smooth edges and faces when you cut plywood.

4. Rip Solid Wood With Confidence

When you’re ripping boards into narrower pieces, you need straight, consistent cuts. That pretty quickly eliminates a regular circular saw as a great tool for ripping. A table saw is often the tool of choice for ripping because the fence guides the wood straight and allows repeat cutting. But a table saw is a lot less portable and requires a lot of infeed and outfeed space. A track saw provides a perfect, portable alternative.

Straight cuts without a table saw

Just like when cutting sheet goods, our Guide Track guides the saw for perfectly straight cuts when ripping solid wood. And the track stays in place without clamps, so all you need to do is mark your width, lay the track down, and rip. You can even connect two Guide Tracks together to rip long boards.

Rip boards with rough edges

With a track saw you can rip a straight line even on boards with rough, crooked, or natural edges. That’s something a table saw can’t do without special jigs and extra steps.

Eliminate kickback

One risk when ripping with a table saw or a circular saw is kickback. That’s caused by the kerf (the area cut out by the blade) closing up and binding on the blade. Our track saw eliminates this risk with a retractable riving knife. It follows the blade to prevent the kerf from closing in around the blade. That means you can make track-saw rip cuts safely.

Add integrated measuring

You can make track-saw ripping even easier by adding our Rip Guides. They easily attach to the track when you want them. Instead of measuring and marking, just adjust the guides to your measurement. Then lay the track down so the guides fit against the board edge, and you’re set to rip accurately—whether you need one cut or many.

Create ready-to-join edges (without a jointer)

With our Adaptive Cutting System Plunge Saw and Guide Track, you can take ripping one step further and use your track saw to dress board edges when you’re creating solid wood panels. Instead of using a jointer, just shave a hair off the mating edges of the boards to get flat, smooth edges that are ready for assembly.

See it in action!

Even surfaced boards don’t always have smooth, straight edges. Our Adaptive Cutting System track saw makes it easy to trim those edges perfectly.

5. Easily Work With Solid-Wood Panels

A track saw is a great tool for working with glued-up panels and large slabs, too. Those are both tough to manage on a table saw, and they need more precision than a circular saw usually provides.

Trim panels easily

Creating glued up panels is a lot easier if you leave the boards a bit long. That way, you don’t have to get the ends perfectly aligned. Just assemble your panel, and then trim the ends to cut the panel to final length. A track saw makes that super easy by giving you straight, clean cuts.

6. Portability Meets Precision: Take Your Track Saw Anywhere

Clearly a track saw can do a lot of things. We’ve just touched on a few here. What makes this such a great tool, though, is that you can do those things anywhere you need to or want to work. That’s why pros adopted these tools right away. It’s also a big advantage for anyone who doesn’t have a dedicated shop space, as well as anyone who works on projects in other locations.

Cut with stability on sawhorses

You can set up a cutting station for your track saw anywhere easily with a couple sawhorses and a cutting-support grid. This knock-down support grid works great for boards and plywood. You can build one for yourself using this plan.

Support sheet-good cuts

Another great option for cutting sheet goods is a piece of 2″-thick rigid-foam insulation. It supports the sheets and keeps pieces from falling when you cut. You can use the foam on sawhorses, or just lay it on the ground.

7. Expand Your Cutting Capabilities

One thing that separates the Plunge Saw + Guide Track Kit from other track saws is that it’s part of our Adaptive Cutting System. That means you can add the Project Table. It’s much more than just a surface where you can do your track-saw cutting. It opens up a world of cutting possibilities that aren’t possible with other track saws.

Make more types of cuts, faster

With the full Adaptive Cutting System—the Plunge Saw, Guide Track, and Project Table—you can do many things a track saw alone can’t. This setup makes it easy to crosscut and miter-cut boards—with much greater width capacity than a miter saw. And you can work with small and narrow pieces easily.

Save time with integrated measuring

The Project Table has adjustable hinges that position the track in the exact same position on the table every time, plus integrated measuring scales and stops to position your materials. With these, you can quickly and accurately set up cuts without having to measure and mark your workpieces.

These examples show some, but not nearly all, of the things you can do with a track saw. You can see pretty easily that it’s not a specialty tool for pros. The Adaptive Cutting System Plunge Saw and Guide Track is a setup that can be a game changer for anyone who wants precise, smooth, repeatable cuts in sheet goods and solid wood. We’re confident that it will become one of your go-to tools for every project you build. You can learn more about our saw—and our complete Adaptive Cutting System—here.