When it comes to getting precise and accurate cuts with a circular saw, using a guide is essential. Using a guide improves cutting performance and assures straight lines. However, it may be difficult to decide which guide is best for your circular saw due to the variety of choices available. We’ll go through the advantages and disadvantages of each choice so you can make the right decision.

How do you cut a perfect line with a circular saw?

Getting a straight cut with a circular saw can be challenging, but it can be accomplished by following a step-by-step process and some practice.

First, you want to make sure the cutline is clearly marked on the workpiece. Then, set the blade’s depth so it’s a hair less than the thickness of the workpiece. The saw needs to be placed so that the blade is parallel to the cutline and the base is flush with the surface you will be cutting. You’ll need to cut slowly and steadily, maintain a firm grip, and keep the saw aligned with the cutline throughout.

Learn more about how to get straight cuts using a circular saw with our step-by-step guide.

Do you need a guide for a circular saw?

Investing in a high-quality guide for your circular saw is one of the best investments you can make in improving the accuracy and efficiency of your woodworking tasks.

Using a guide for a circular saw ensures accurate and straight cuts by acting as a reference point. It is particularly useful for large projects or cutting large sheets of material. You’ll have more control and stability with a guide, leading to cleaner cuts with less splintering. Having a regular cutting line provided by a guide also reduces the amount of time wasted on measuring and marking.

How does a circular saw guide work?

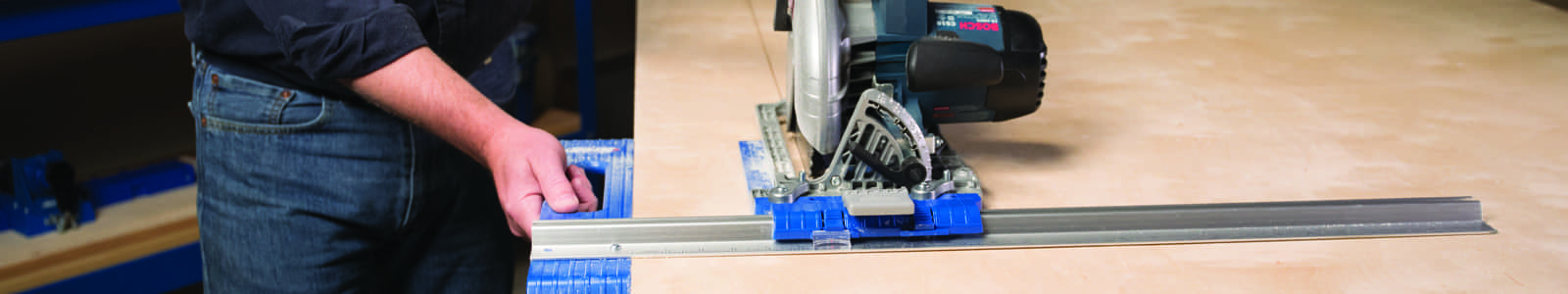

A circular saw guide consists of a straight track that serves as a stable cutting path. The saw’s base attaches to the track, allowing it to glide smoothly along. By aligning the saw’s base with the rail, you can make straight and accurate cuts without the need for manual measurements.

The guides versatility makes it suitable for various cutting tasks, such as ripping plywood, crosscutting, and bevel cuts. It ensures consistent and repeatable results, and is particularly useful when multiple identical pieces are needed.

Learn more about how to achieve straight cuts using a circular saw guide.

![]()

What can you use as a guide for a circular saw?

There are a number of options for circular saw guides, each with its own advantages and disadvantages. You’ll need to consider the resources involved, cost of each, the specific requirements of your project, and the level of precision needed when choosing the most suitable guide for your circular saw.

Rip fence

A rip fence, or base-mounted guide, is included with many circular saws. It aids in keeping the blade at a constant distance from the edge of the workpiece, helping make cuts that are straight and parallel to the edge.

Pros:

- Some circular saws have them built in, so you always have a reference handy.

- Helps with parallel cuts along the edge of your workpiece.

- Can make rip cuts of varying widths by adjusting and locking into place.

Cons:

- Limited to guiding cuts parallel to the edge of the workpiece.

- May not provide the same level of accuracy as specialized guide systems.

- For some cuts, the workpiece size may be limited by the rip fence’s length.

Homemade jig or template

For specific shapes or repetitive cuts, you can create a custom jig or template. These guides are pre-made or homemade fixtures that guide the circular saw along a predetermined path.

Pros:

- Adaptable to different sizes and shapes for cutting.

- Good for both straight and curved lines.

Cons:

- You’ll need to put in some work making the jig or template.

- May not provide the same level of precision as other guide options.

Measuring tools

Temporary guides for quick straight cuts can be made with combination squares, T-squares, or any other measuring tool with a straight edge.

Pros:

- Simple to use and can be found in nearly every toolkit.

- Useful as a makeshift map for quick detours along straight paths.

Cons:

- It’s not built to be a guide, so there’s a chance it won’t stay in place while you’re cutting.

- Because of how small the ruler is, you can only make very short cuts.

- Needs more fastening or clamping to keep it in place.

Guide track

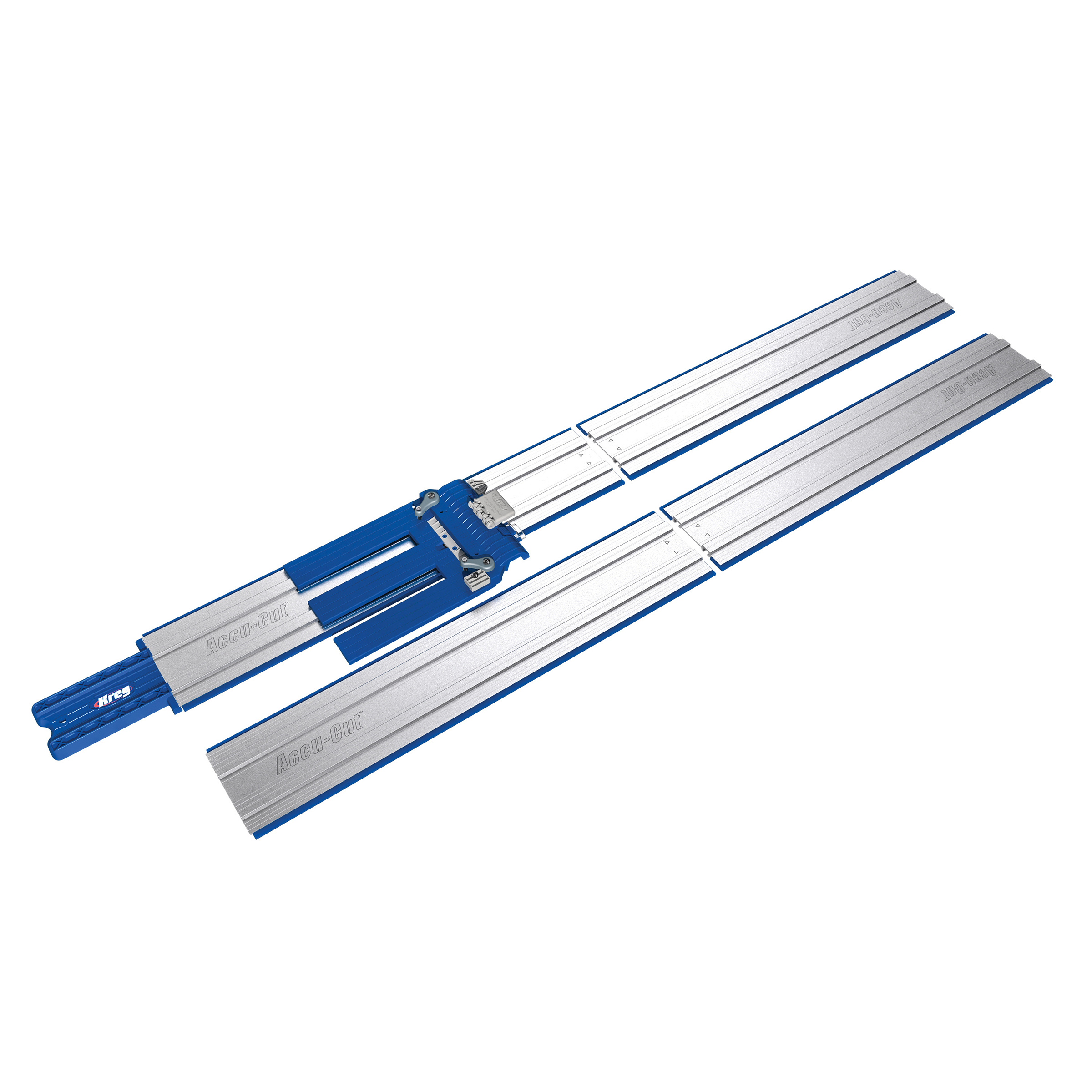

Also known as a rail or a fence, a guide track is a specialized accessory designed specifically for guiding circular saws. It gives the saw a nice, straight line to follow, so you can make clean cuts every time. Anti-slip strips or clamps are common accessories for guide tracks.

Pros:

- High accuracy and the guarantee of perfectly straight cuts, even over longer material lengths.

- Anti-slip features keep things steady while you cut.

- Some guide rails have additional features like measurement scales for added convenience.

Cons:

- Larger size means it will need more room to be stored.

- Compatibility may vary between different circular saw models and track systems.

![]()

Are circular saw guides universal?

Circular saw guides are not universally compatible across all circular saw models.

Manufacturers will often create cutting guides that are unique to their own circular saws or that are compatible with their systems. This means that some circular saws may not work with guide from other brands, and vice versa. Fortunately, the Universal Sled on the Kreg Accu-Cut™ and Kreg Rip-Cut™ accepts most circular saws, either left or right blade.