Joining two pieces of wood together in a way that is both secure and good looking is a fundamental skill. Among various joinery techniques, loose tenon joinery has gained popularity for its versatility, strength, and ease of use. We’ll walk you through everything you need to know about loose tenon joinery, from its basic principles to advanced applications.

What is Loose Tenon Joinery?

Loose tenon joinery, also known as floating tenon joinery, is a woodworking technique that uses a separate piece of wood (the loose tenon) to join two workpieces.

Unlike traditional mortise and tenon joints — where a mortise is created in one workpiece and another has a corresponding integral tenon cut into it — loose tenon joinery involves creating matching mortises in both pieces and then inserting a separate (loose) tenon.

Components of a loose tenon joint:

Mortises

Precisely cut slots in both pieces of wood to be joined.

Loose tenon

A separate piece of wood, typically rectangular, that fits into the mortises.

Adhesive

Usually wood glue, used to secure the tenon in place.

How loose tenon differs from traditional mortise and tenon

In a traditional mortise and tenon joint, one piece of wood (the rail) has a protruding tenon cut directly into it, while the other piece (the stile) has a matching mortise. Loose tenon joinery, on the other hand, requires mortises to be cut in both pieces, with the separate tenon bridging the gap between them.

This approach offers several advantages in terms of ease of construction and versatility, making it a more approachable joinery method for beginning woodworkers.

Advantages of loose tenon joinery

Ease of use and accessibility

Simpler than cutting tenons to matching mortises

Allows for easier assembly of complex joints

Can be done with a wider range of tools, including basic hand tools

Precision and strength

Offers excellent alignment and precise fit

Provides large gluing surface area for strong joints

Allows for fine-tuning of fit by adjusting the tenon size to be looser or tighter in mortises

Versatility in various woodworking projects

Suitable for a wide range of applications, from small boxes to large furniture

Easily adaptable to different wood thicknesses

Can be used for both structural and decorative joints

Comparison with traditional mortise and tenon joinery

Faster than cutting traditional tenons

More forgiving of small errors in mortise placement

Tools and materials required for loose tenon joinery

Types of Loose Tenon Joinery

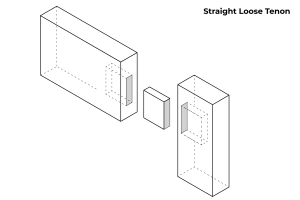

1. Straight loose tenon:

The most common type, using a straight, rectangular piece of wood as the tenon. Ideal for joining pieces at 90-degree angles or in straight-line applications.

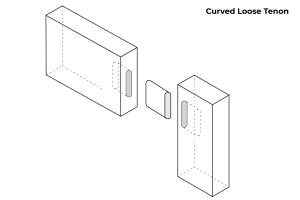

2. Curved loose tenon:

Used for joining curved pieces or creating curved assemblies. The tenon itself is curved to match the arc of the joined pieces.

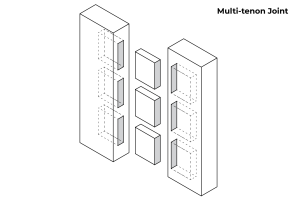

3. Multi-tenon joints:

Employing multiple smaller tenons instead of one large one. This approach distributes stress more evenly and can be stronger in certain applications.

4. Floating spline joints:

A variation where a thin, wide tenon (spline) is used, often visible on the outside of the joint. This can add both strength and decorative elements to the project.

Tools and Materials Required For Loose Tenon Joinery

Essential tools

Router or drill press for cutting mortises

Chisels for cleaning up and squaring mortises

Saw (table saw, band saw, or hand saw) for cutting tenon stock

Measuring and marking tools (squares, marking gauges, pencils)

Clamps for assembly

Update (November 2024): Kreg just released their latest tool called the MortiseMate which allows DIYers to cut mortises with just a drill. No router needed!

Recommended materials for tenons and mortises

Hardwoods like oak, maple, or beech for tenons in high-stress joints

the same species as the joined pieces or a complementary wood for Visible joints

Plywood or manufactured wood products for certain applications

Safety equipment and best practices

Safety glasses and hearing protection when using power tools

Dust mask or respirator for protection against dust

Proper ventilation in the workshop

Choosing the right wood for tenons

Select straight-grained, knot-free wood for maximum strength

Consider using quarter-sawn stock for stability in larger tenons

Match the wood species to the project

Step-by-step guide to creating loose tenon joints

1. Measure and mark

a. Determine the size and placement of your mortises

b. Mark the mortise locations clearly on both pieces to be joined

c. Use a marking gauge or a tool like the Multi-Mark™ to ensure consistent depth and width

2. Cut the mortises

a. Set up your router or drill press with an appropriate bit

b. Make multiple passes to reach the desired depth, cleaning out waste between passes

c. Use a chisel to square up the ends of router-cut mortises if necessary

3. Prepare the loose tenons

a. Cut tenon stock slightly oversized in width and thickness

b. Plane or sand the tenons for a snug fit in the mortises

c. Round over the edges slightly to ease insertion

4. Fit and assemble the joints

a. Test fit the tenons in both mortises, adjusting as necessary

b. Apply glue to the mortises and tenon

c. Insert the tenon and clamp the joint, checking for square

5. Finishing touches and adjustments

a. Clean up any squeeze-out before the glue dries

b. Once dry, sand or plane any protruding material flush with the surface

c. Apply finish as desired

The Kreg MortiseMate simplifies mortise cutting, combining the precision of a router with the simplicity of a drill. Featuring an auto-indexing step-down mechanism, micro adjustment screws, and integrated mini work surface, the MortiseMate makes it easy to create professional-quality hidden joints with just a drill.

Applications of loose tenon joinery

Common projects utilizing loose tenon joints:

Table and chair construction

Cabinet face frames and doors

Bookcases and shelving units

Picture frames and mirrors

Furniture making

Joining table legs to aprons

Connecting chair rails to legs

Attaching headboards and footboards to bed frames

Creating strong corner joints in dressers and chests

Doors and frames

Joining stiles and rails in frame-and-panel doors

Constructing sturdy door frames

Creating window sashes and frames

Decorative woodworking

Joining mitered corners in boxes and small containers

Creating intricate geometric patterns in cutting boards or wall art

Assembling complex shapes in sculptural pieces

Structural uses in larger woodworking projects

Timber frame construction elements

Outdoor furniture and structures (pergolas, arbors)

Boat building and repair

Tips and techniques for perfect loose tenon joints

Ensuring alignment

Use a router template or jig for consistent mortise placement

Create a setup block to quickly set router depth for multiple identical joints

Consider using a Festool Domino or similar specialized tool for rapid, precise joints

Troubleshooting common issues

Loose fit

Make a new, slightly larger tenon or use shims

Tight fit

Sand or plane the tenon carefully for a smooth insertion

Misaligned mortises

Use a slightly oversized tenon and trim to fit

Enhancing joint strength and durability

Size tenons appropriately — generally 1/3 to 1/2 the thickness of the joined pieces

Use multiple smaller tenons instead of one large one for wider stock

Consider adding reinforcement pins for high-stress joints

Creative uses and innovative designs

Experiment with contrasting woods for decorative exposed tenons

Use curved tenons for joining curved pieces or creating bent laminations

Combine loose tenon joinery with other techniques for unique effects

Comparing loose tenon joinery with other joinery methods

Traditional mortise and tenon joints vs loose tenon joints

Pros of loose tenon

Easier to create precise fits

More versatile for angled joints

Allows for easier dry-fitting and adjustment

Cons

May not be as strong in some applications

Requires creating two mortises instead of one

Pocket-hole joinery

Pros of loose tenon

Stronger and more durable joint

No visible screw holes

Better for solid wood construction

Cons

More time-consuming to create

Can require more specialized tools

Biscuit joinery

Pros of loose tenon

Stronger joint, especially for end-grain connections

More precise alignment

Greater versatility in joint types

Cons

Takes longer to create than biscuit joints

Requires more careful layout and execution

Doweling

Pros of loose tenon

Easier to create precise alignment

More forgiving of slight misalignments

Often stronger, especially in larger joints

Cons

May take longer to execute than simple dowel joints

Requires more specialized tools for efficient production

FAQs about loose tenon joints

How strong is a loose tenon joint?

A properly executed loose tenon joint can be as strong as a traditional mortise and tenon joint, offering excellent strength and stability due to its large gluing surface and mechanical interlocking properties.

How long should loose tenons be?

Loose tenons should typically be 1/3 to 1/2 the thickness of the joined pieces and extend into each piece by at least 1-1/4 inches, with longer tenons used for larger or high-stress joints.

Are loose tenons stronger than dowels?

Loose tenons are generally stronger than dowels, especially for larger joints or those subject to significant stress, as they provide a larger gluing surface and better resistance to twisting forces.

What is the depth of a loose tenon?

The depth of a loose tenon mortise should typically be slightly longer than half the length of the tenon, allowing the tenon to extend fully into both joined pieces while leaving a small gap in the center for glue and potential wood movement.

To learn more about the new MortiseMate loose tenon jig, check out this video: