Workshop Drill Press Cabinet

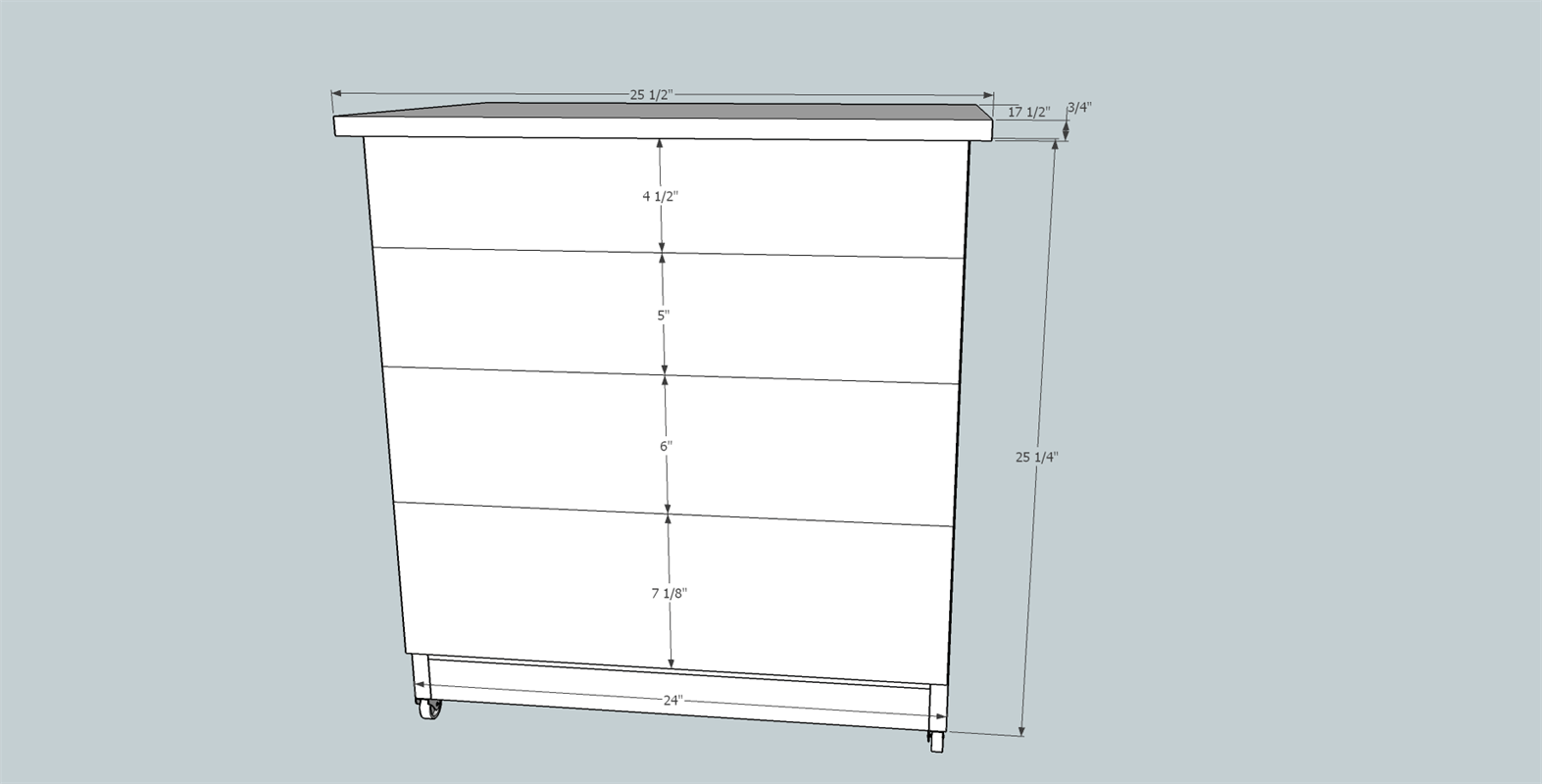

By fcbeckerEvery workshop needs more storage. This easy to build Drill Press Cabinet provides 4 drawers of storage for all of your drill bits and accessories. Mounted on casters it can be moved from the drill press and used as a handy extra bench top. Uses only 1 4X8 sheet of 3/4" plywood and 1 1X8X96" board.

Directions

-

Introduction

Please be sure to read through complete instructions before you begin any work on this project. Also keep in mind that plywood may be slightly thinner than its stated thickness. 3/4" plywood may actually be 23/32". So some minor adjustments to plans may be required. Another good practice to use is, after the original carcass is assembled cut to fit all additional pieces that are needed. While every effort was made to make the cut dimensions listed as accurate as possible, cutting to fit will adjust for any slight discrepancies in your assembly.

-

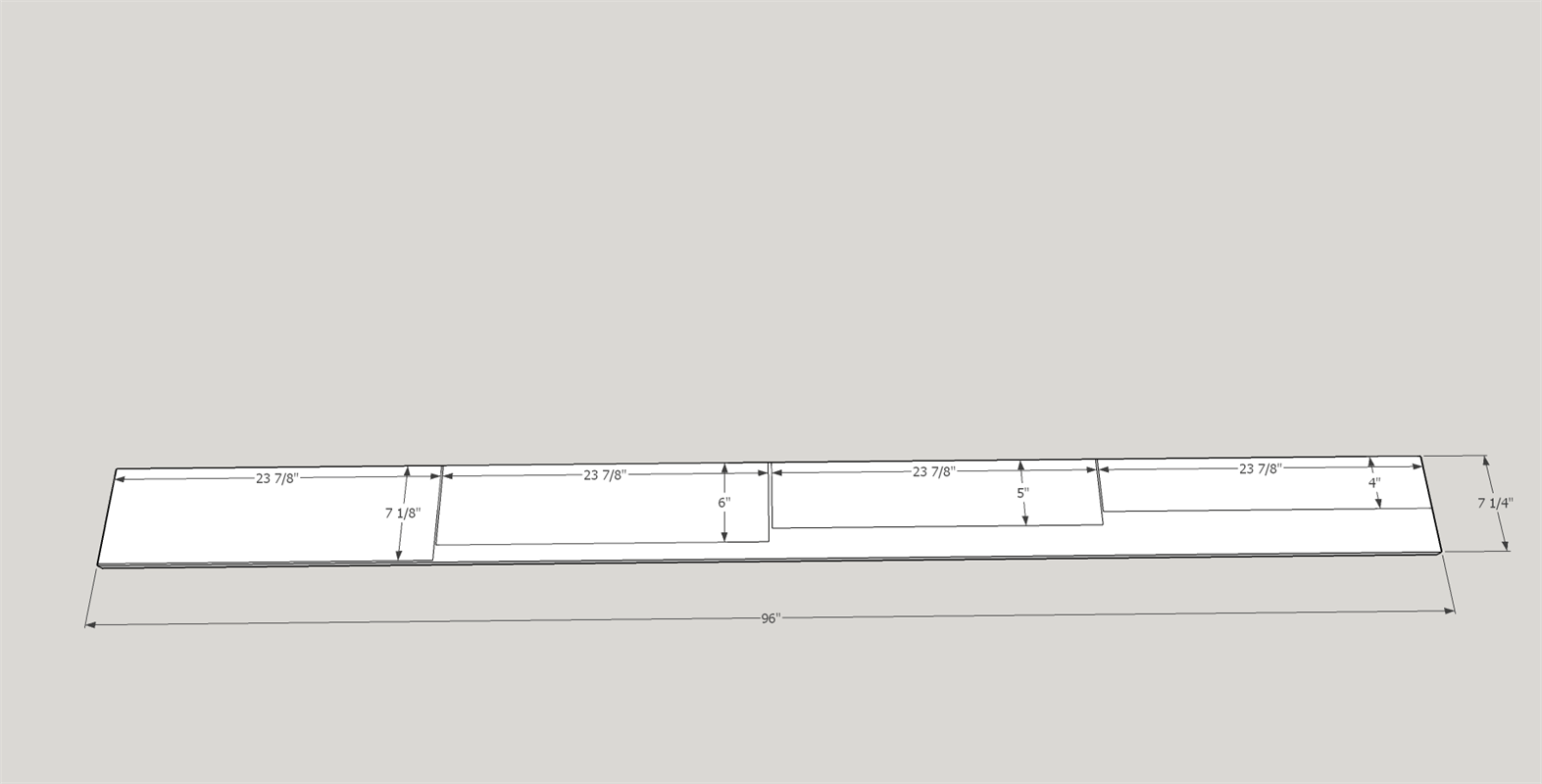

Cut plywood pieces

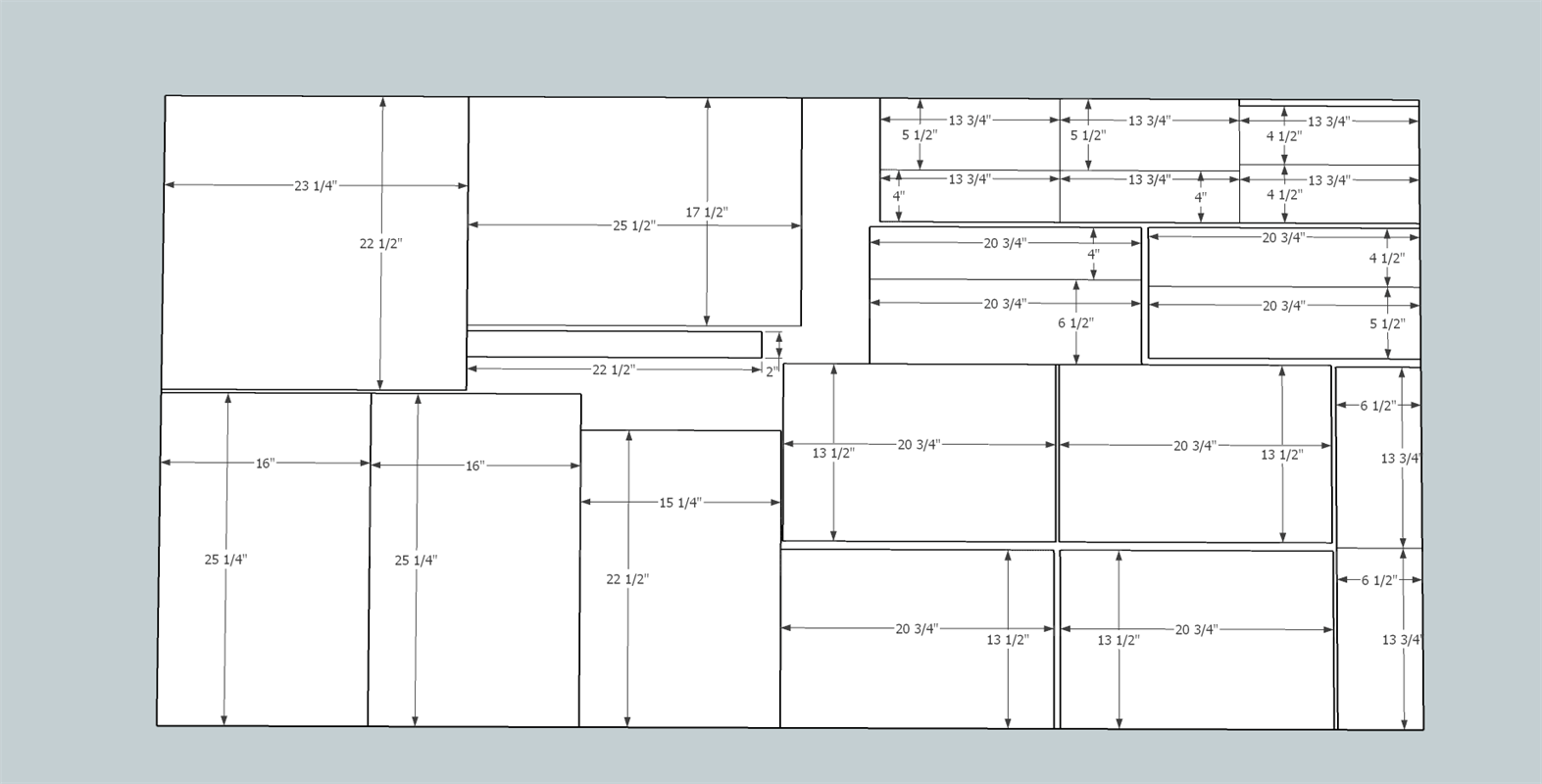

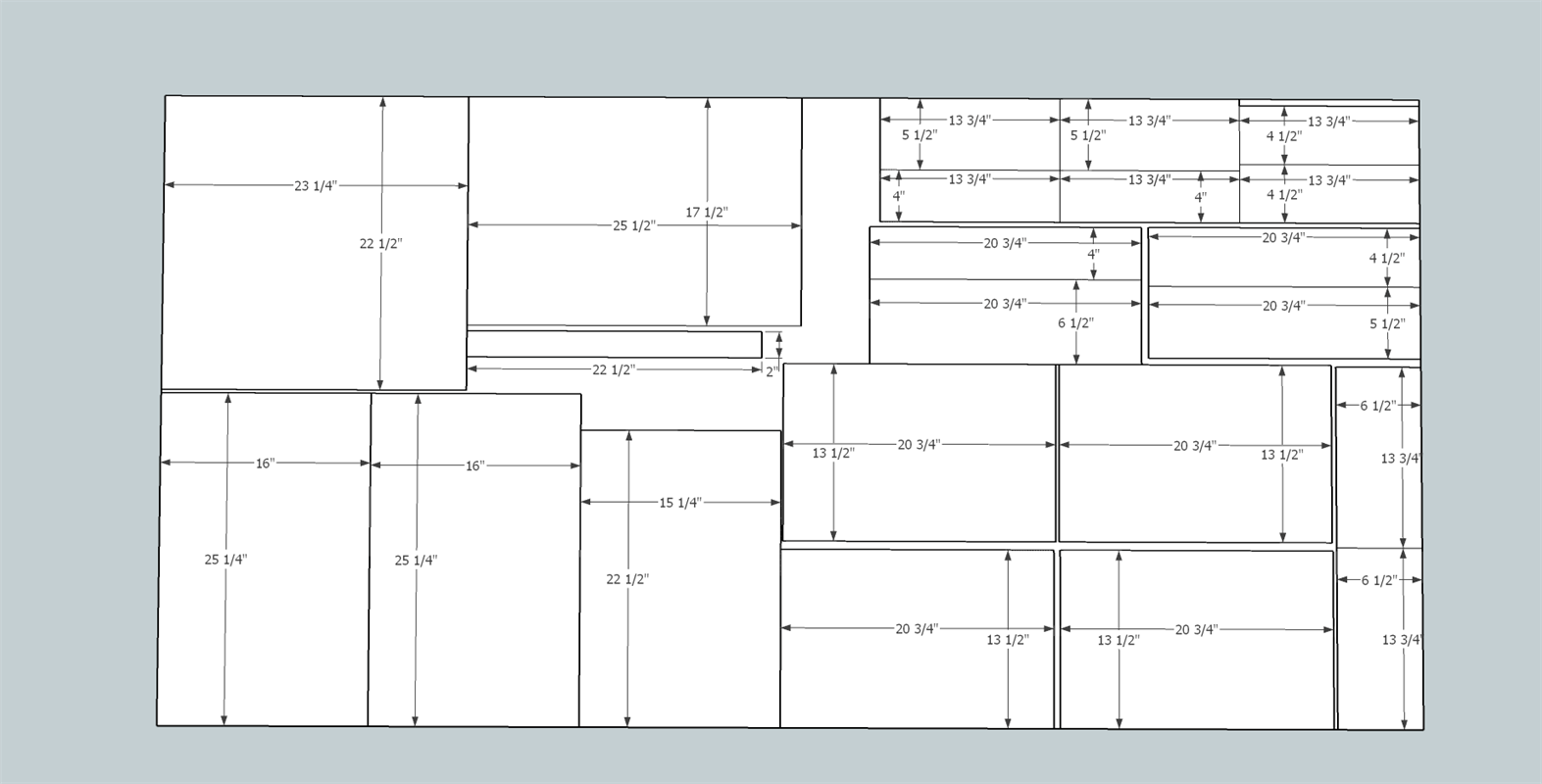

Cut the cabinet sides, bottom, top, back, front apron and drawer parts from the 3/4" plywood sheet. Please note that in the picture of my completed cabinet the top was made from laminated MDF with a poplar frame. I actually assembled the cabinet carcass and drawers from materials left over from other projects. However, as mentioned in the description, the plan was drawn to use one sheet of plywood and one 1X8X96" board.

-

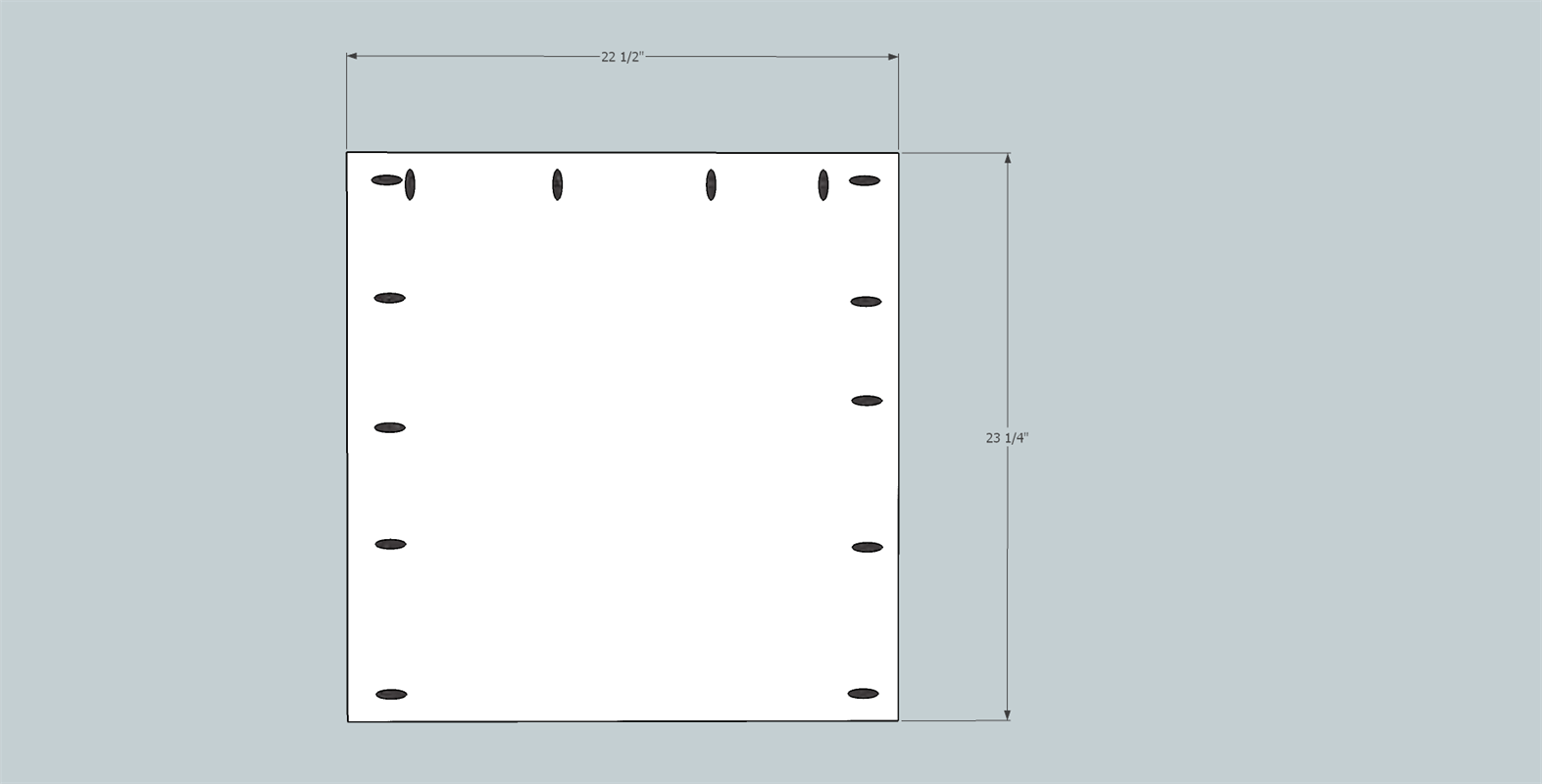

Add pocket holes to bottom

Use Kreg pocket hole jig (set to 3/4" for all pockets on this project), to drill pocket holes in both ends and the back edge of the 3/4" plywood bottom cut in step two. It is a good idea to mark where you are putting the holes to prevent mistakes.

-

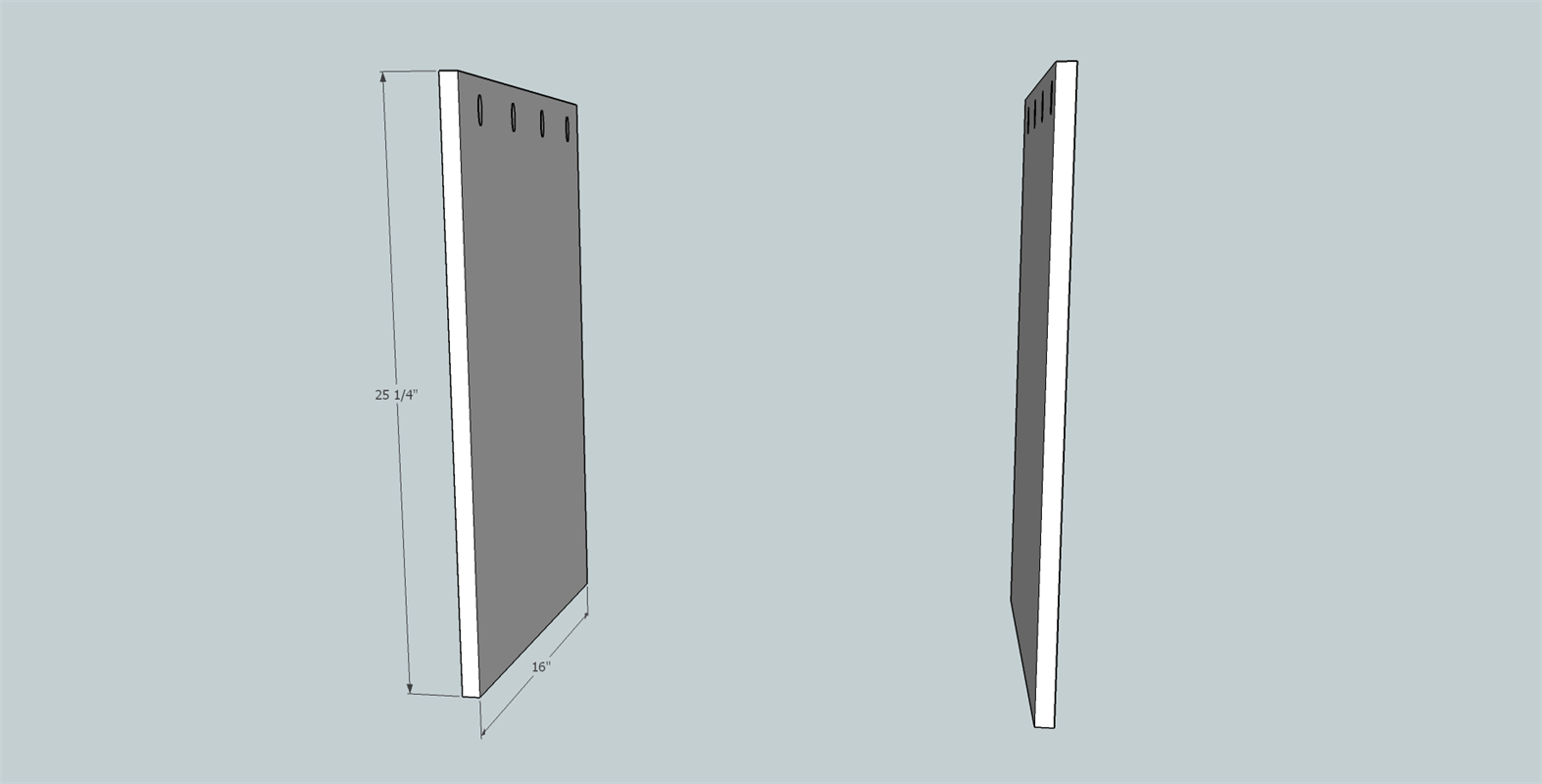

Add pocket holes to sides

Using Kreg pocket hole jig , drill pocket holes in the tops of both of the 3/4" plywood sides cut in step two. It is a good idea to mark where you are putting the holes to prevent mistakes.

-

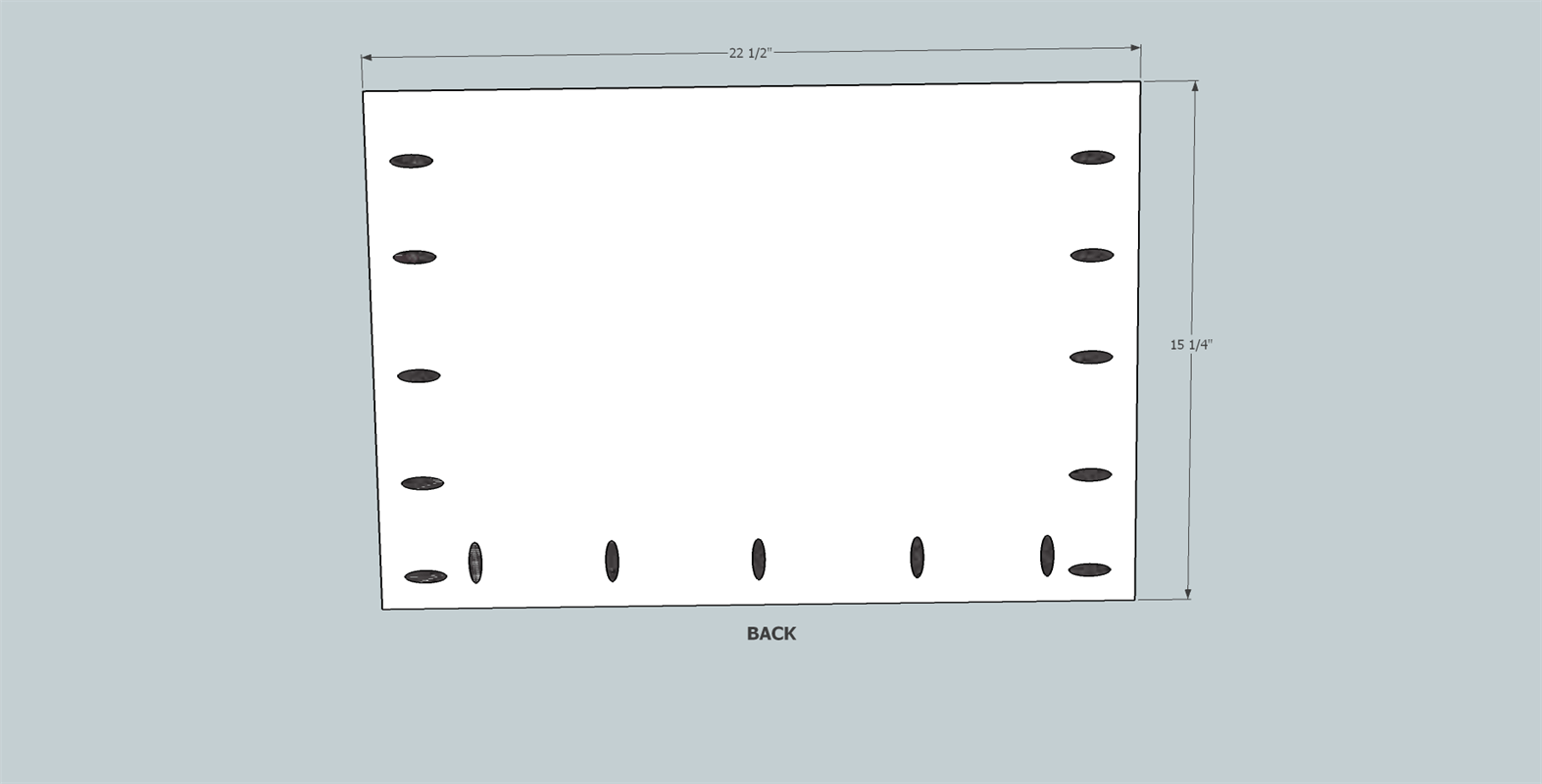

Add pocket holes to back

Using Kreg pocket hole jig , drill pocket holes in the top and both sides of the 3/4" plywood back cut in step two. It is a good idea to mark where you are putting the holes to prevent mistakes.

-

Edge band the top

Attach wood veneer edge banding to the four edges of the top. I use banding with heat activated glue. I use an old electric iron to heat the edging. Once it has cooled cut and sand away any excess veneer. (http://www.joewoodworker.com/veneering/edgebanding-guide.htm) Alternatively you can frame the outside with thin strips of wood which can be glued and pin nailed in place.

-

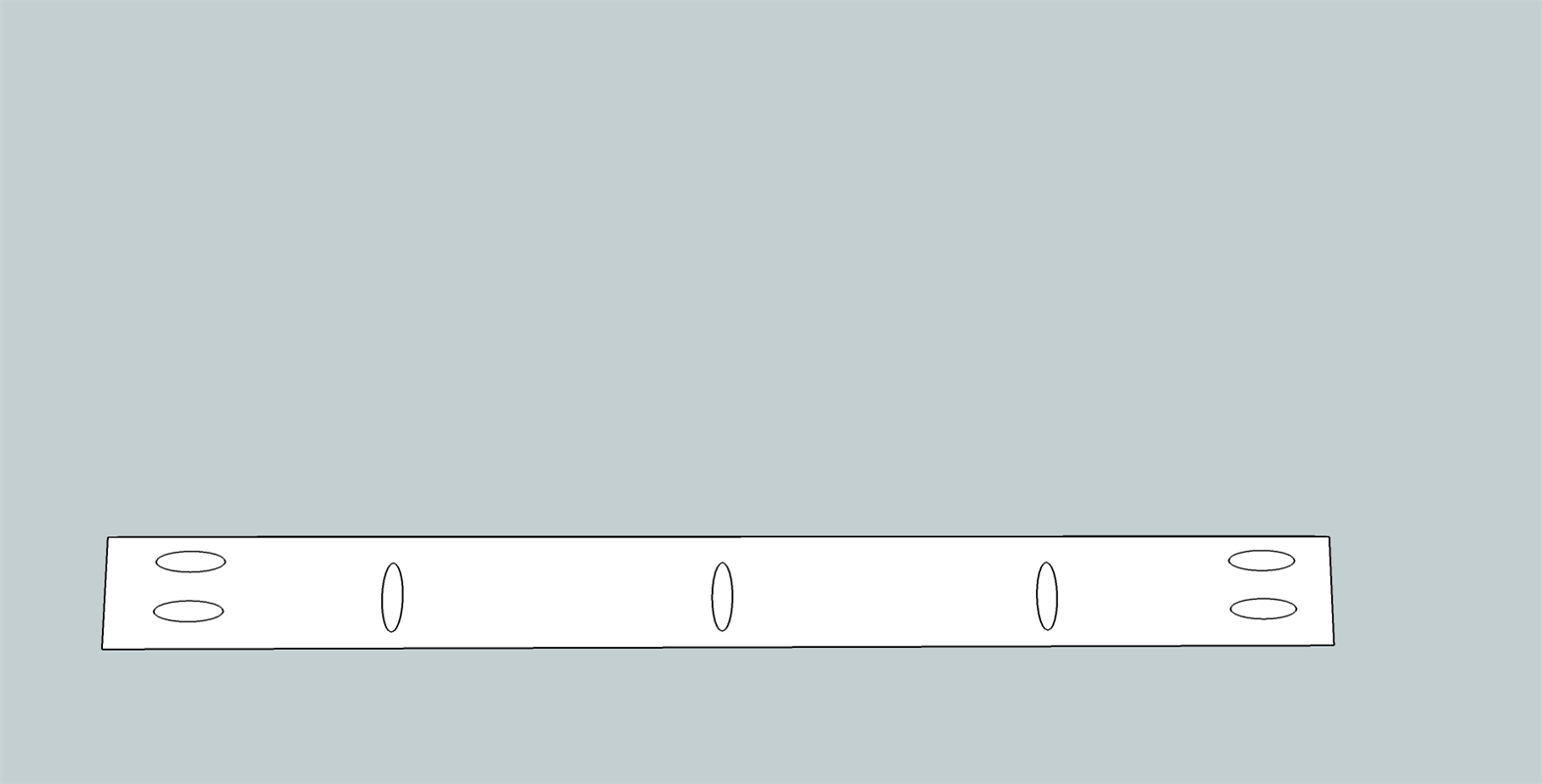

Add pocket holes to the front apron

Using Kreg pocket hole jig , drill pocket holes in the top and both sends of the 3/4" plywood front apron in step two. It is a good idea to mark where you are putting the holes to prevent mistakes.

-

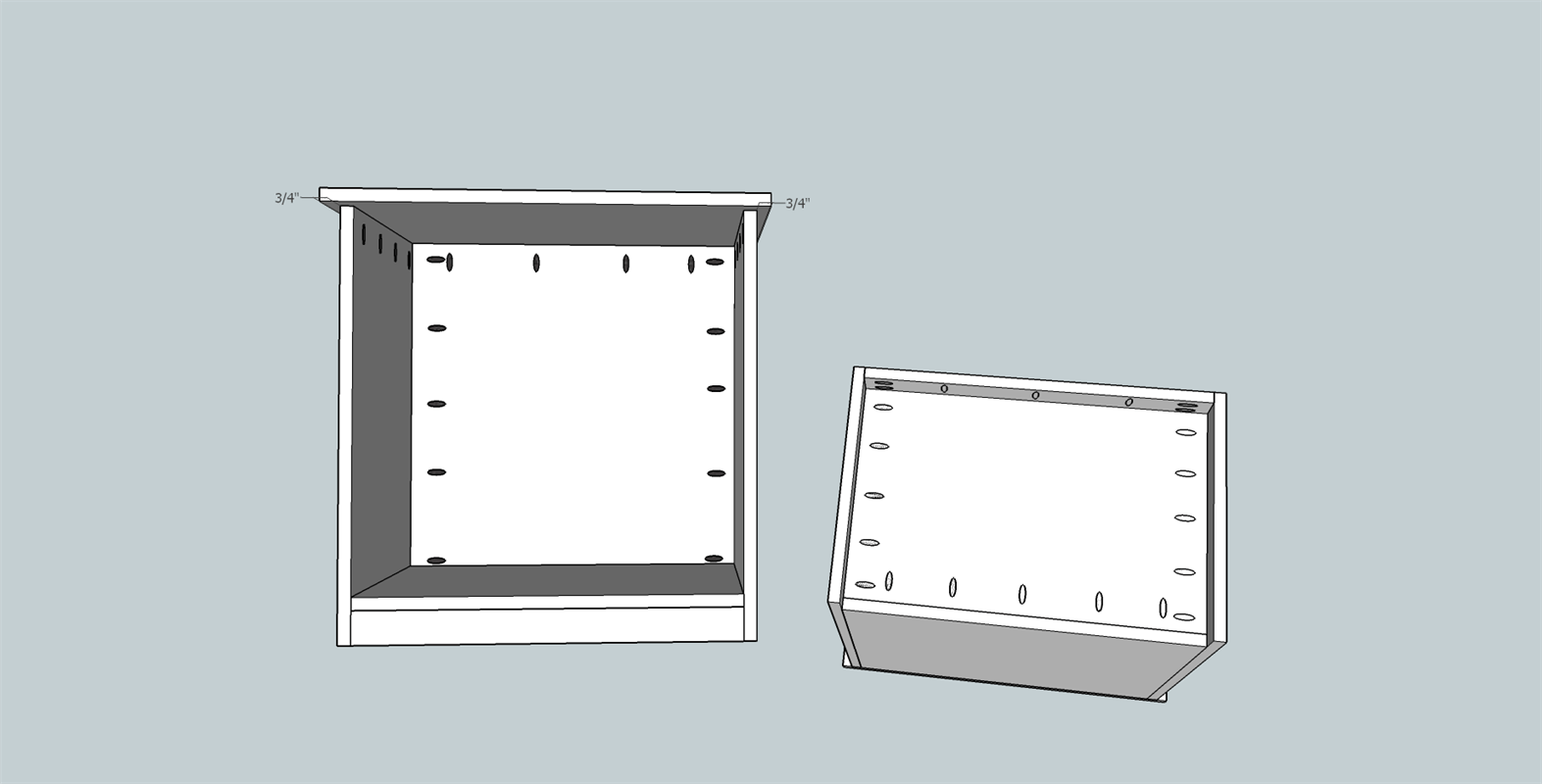

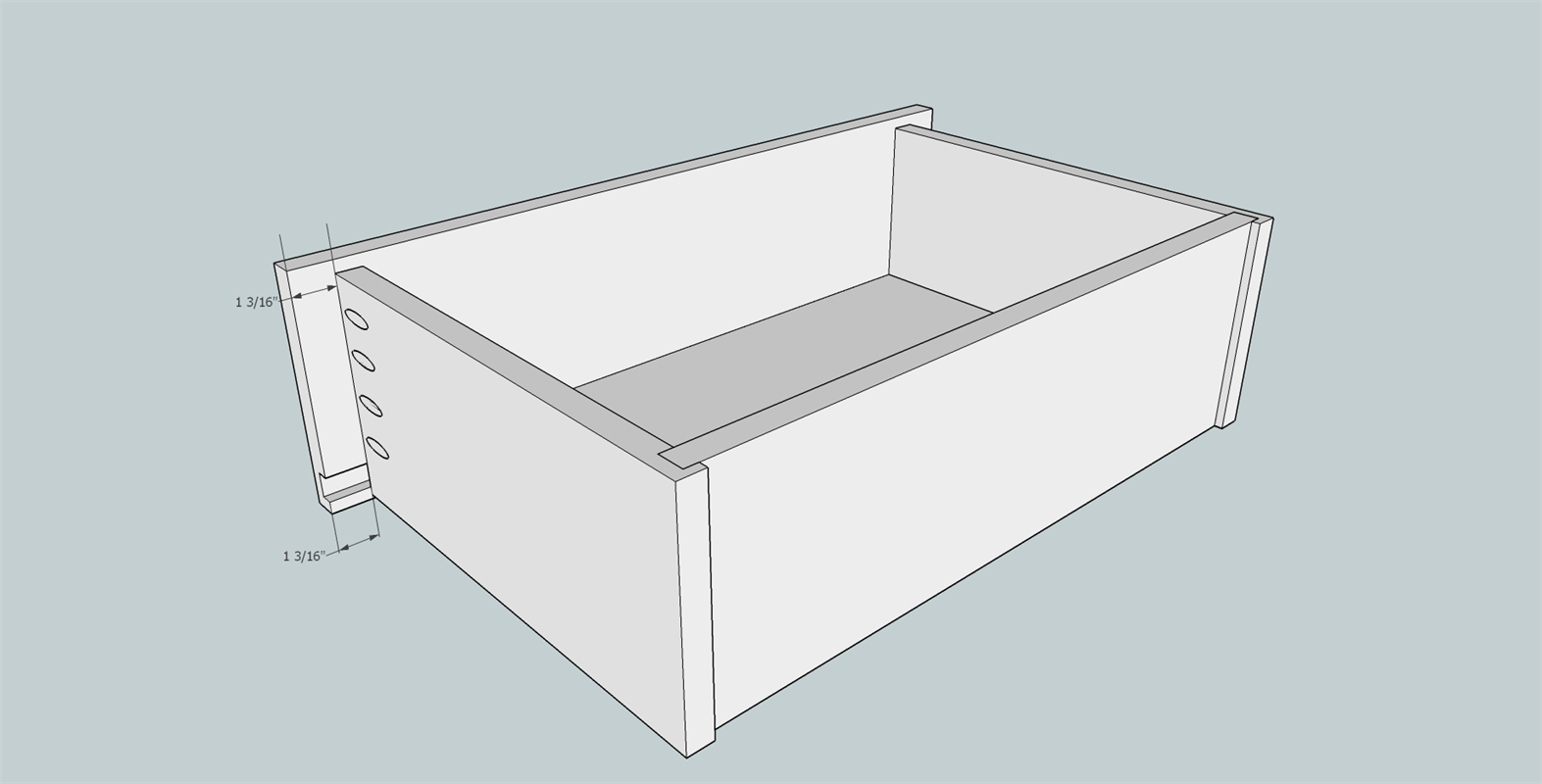

Assemble the carcass

Sand all of the pieces that you have prepared so far. I normally use 100 grit to begin with and finish up with 150 grit. It is much easier to complete this phase of sanding before you begin assembly. I will use 220 grit for a final hand sanding after assembly is complete. Using Kreg 1 1/4" coarse pocket screws and Titebond I wood glue assemble the carcass. The top should be flush with the outside back and should overlap 3/4" on either side.

-

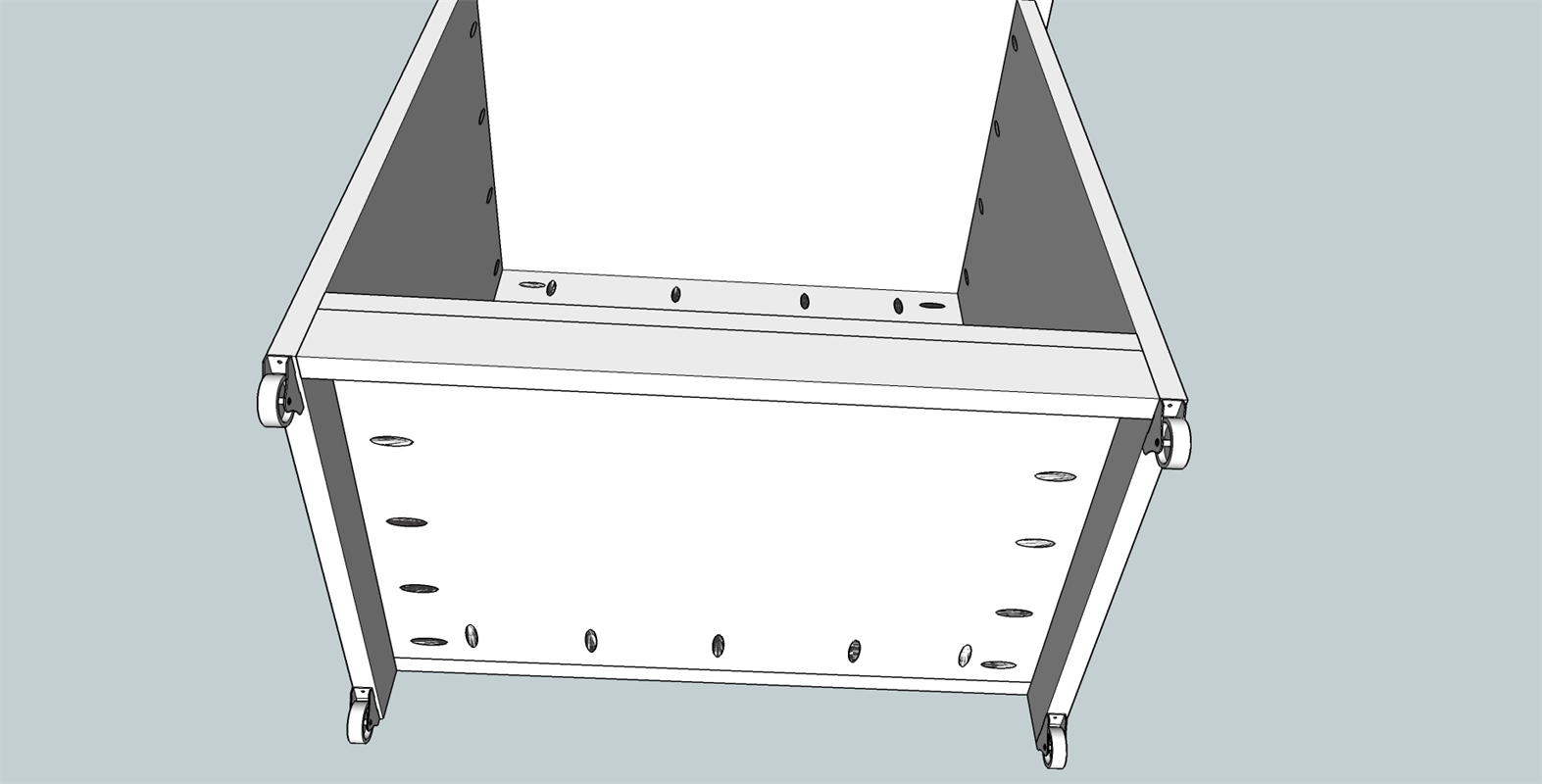

Attach the casters

Attach the casters to the bottom of the cabinet as shown.

-

Attach the drawer slides

Attach the drawer slides as recommended by the slide manufacturer. I used Blum 230M style slides. You can use any type of drawer slide you like to use. However, there are a few things you need to keep in mind. The thickness of the slides will impact how wide you make your drawer box. If the plywood you use to make the drawer box is slightly thinner than 3/4" you might need to adjust the dimensions to insure a proper fit. Finally the slides must be placed exactly the same on both sides and kept square to the carcass to insure that the drawers will move easily.

-

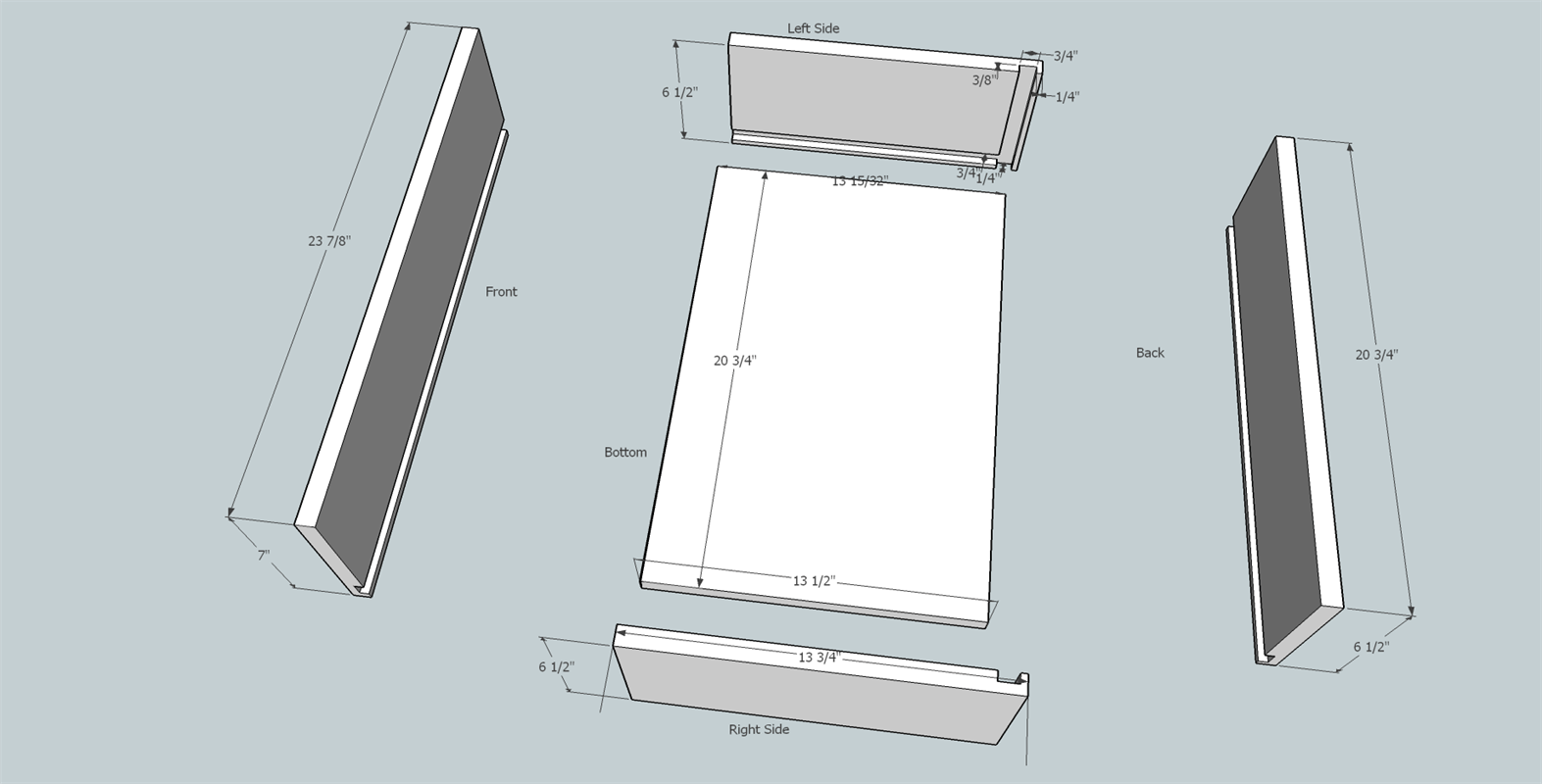

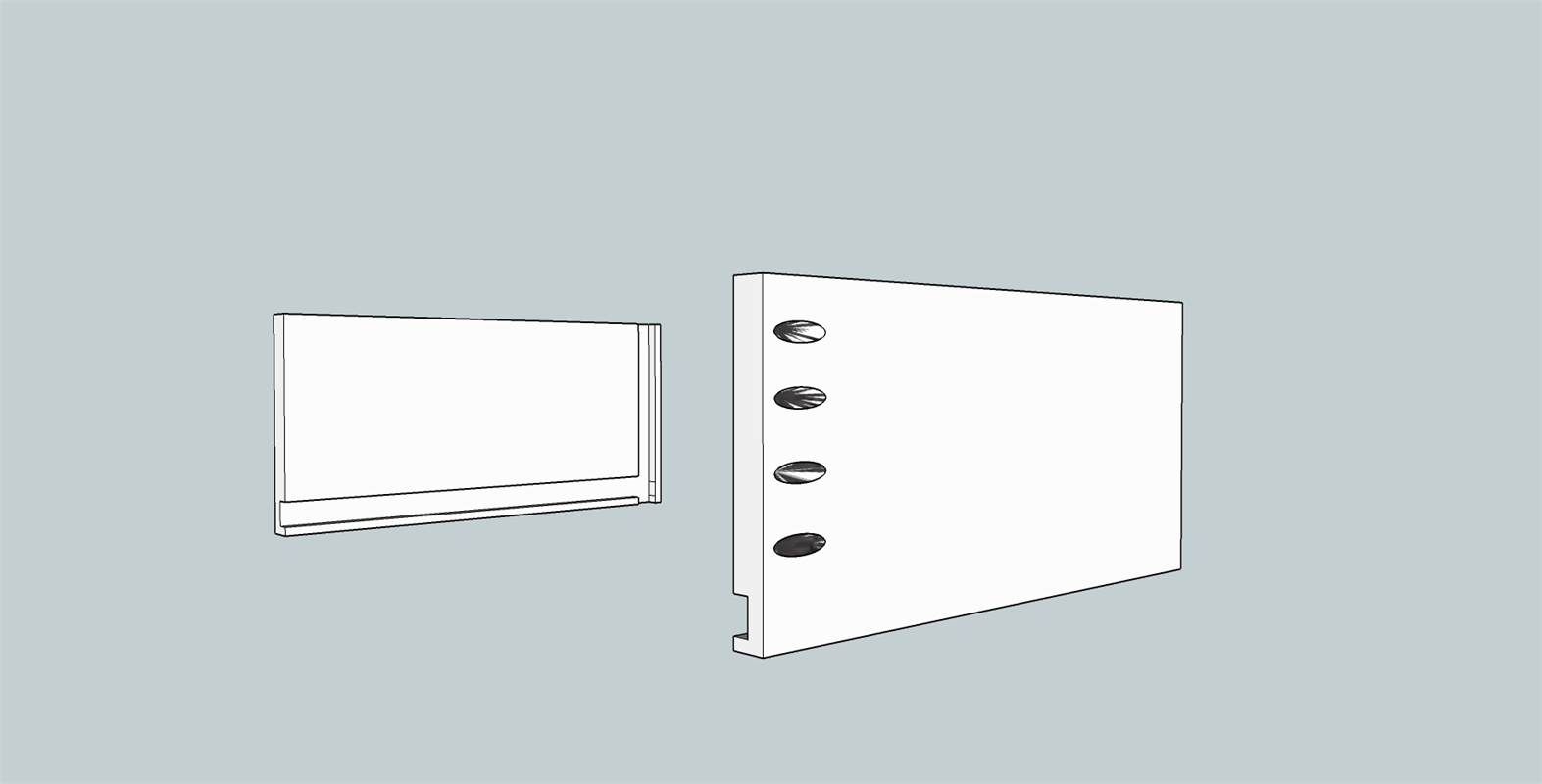

Building the drawers

As I mentioned in step 10 the drawer size will be impacted by the type of slide you use. All dimensions listed in this set of instructions assumes the use of Blum 230M 14 3/4" extension slides. For each set of drawer materials use a table saw to cut a 3/8" deep X 3/4 inch wide dado 3/8" from the bottom of the drawer front and 1/4" from the bottom of the sides and back. Then use a table saw to cut a 3/8" deep X 3/4 inch wide dado 1/4" in from the back of each drawer side. Keep in mind that each set of sides has a left and right...they are mirror images so make sure you are cutting the dados in the correct locations.

-

Cutting the drawer fronts.

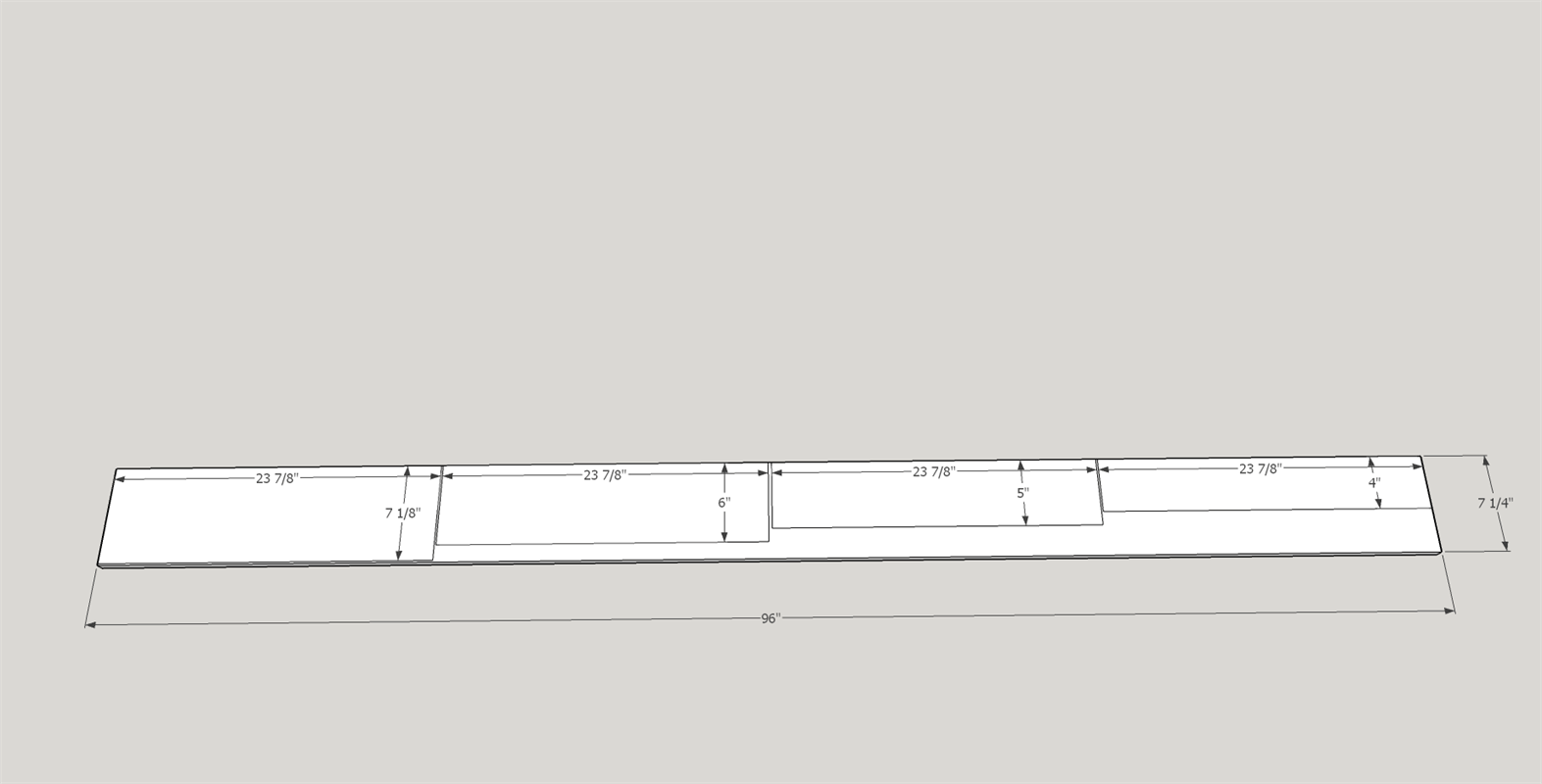

Cut the four drawer fronts from the 1X8X96" board. I used poplar for my cabinet.

-

Add pocket holes to drawer sides

Drill pocket holes at the front outside edge of each set of drawer sides. These will be used to attach the drawer fronts.

-

Assemble drawers

Sand all of the pieces ending with 150 grit for final finish. Sort each drawer assembly by size. For each drawer assemble the two sides, back, and bottom using wood glue in the dados and on the edges of the plywood bottom. Attach the front using wood glue and Kreg 1 1/4" coarse pocket hole screws. You can either clamp until the drawers are dry or use brad nails in the sides and back. Repeat this process three more times until all drawer boxes are complete.

-

Attach Blum drawer profile

If you use the Blum 230M series slides attach the drawer slide profiles to the outside bottoms of each drawer. Keep in mind that each has a left and right slide. If you use another type of drawer slide complete the attachment to the drawer box now.

-

Finish

Now that the build is complete use 220 sandpaper to do a once over on all surfaces in preparation for the finish. Clean well to remove all dust. (I use compressed air and clean dry rags) I did not use a stain, just finished with Minwax Polycrylic Satin finish. I gave the cabinet and drawer assemblies three coats each following manufacturers instructions. After the finish has dried add drawer pulls.