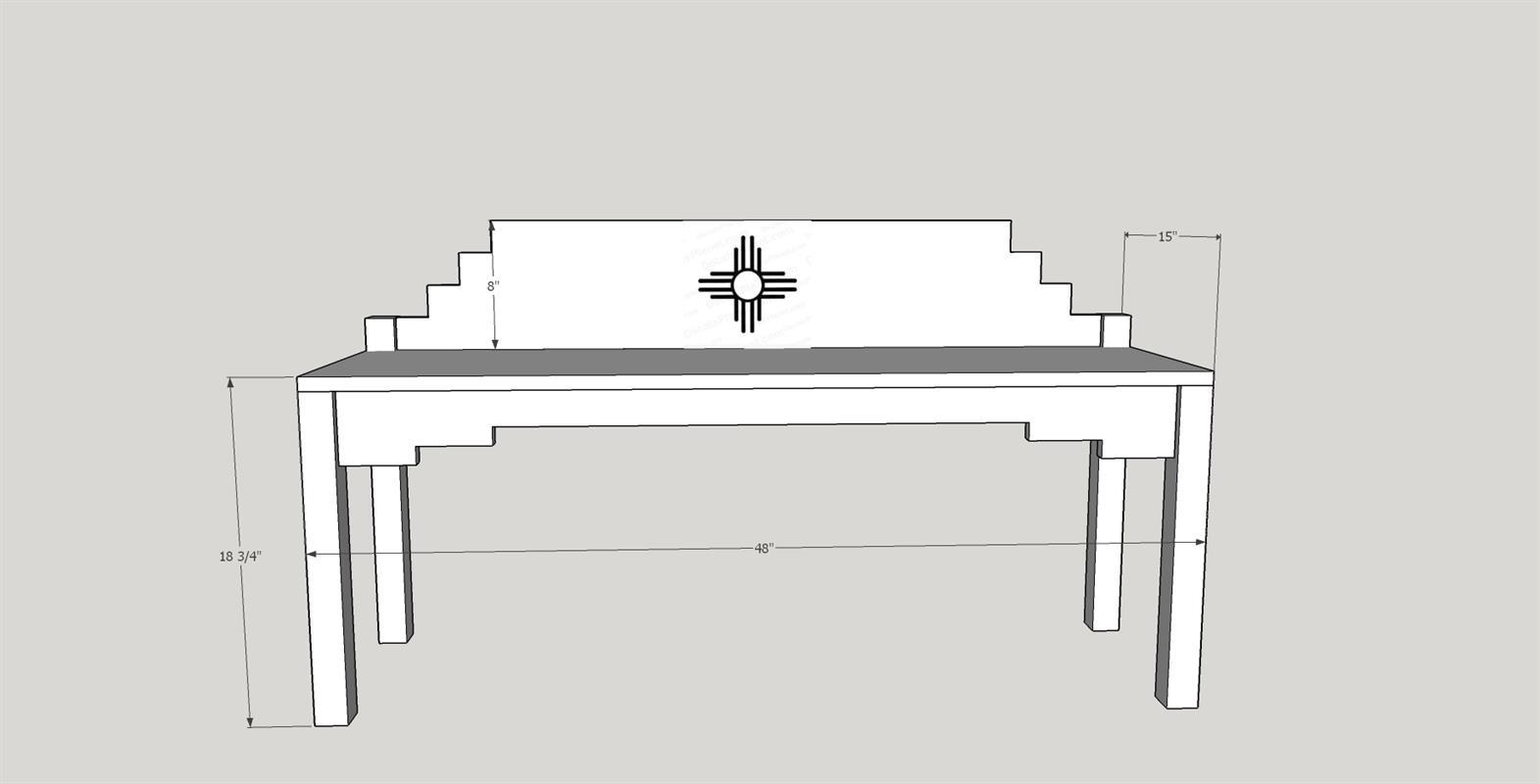

Southwestern Style Bench

By fcbeckerThis small yet durable bench built with oak in the style of the American Southwest is adorned with the Zia Pueblo’s sign of friendship among the peoples. It will make a beautiful addition to your home, use either inside or outside. Build this and share a future heirloom with those you love.

Directions

-

Introduction

Please be sure to read through complete instructions before you begin any work on this project. I developed these plans for an exterior bench. If you plan to use it inside your home you can use regular wood glue and finishes.

-

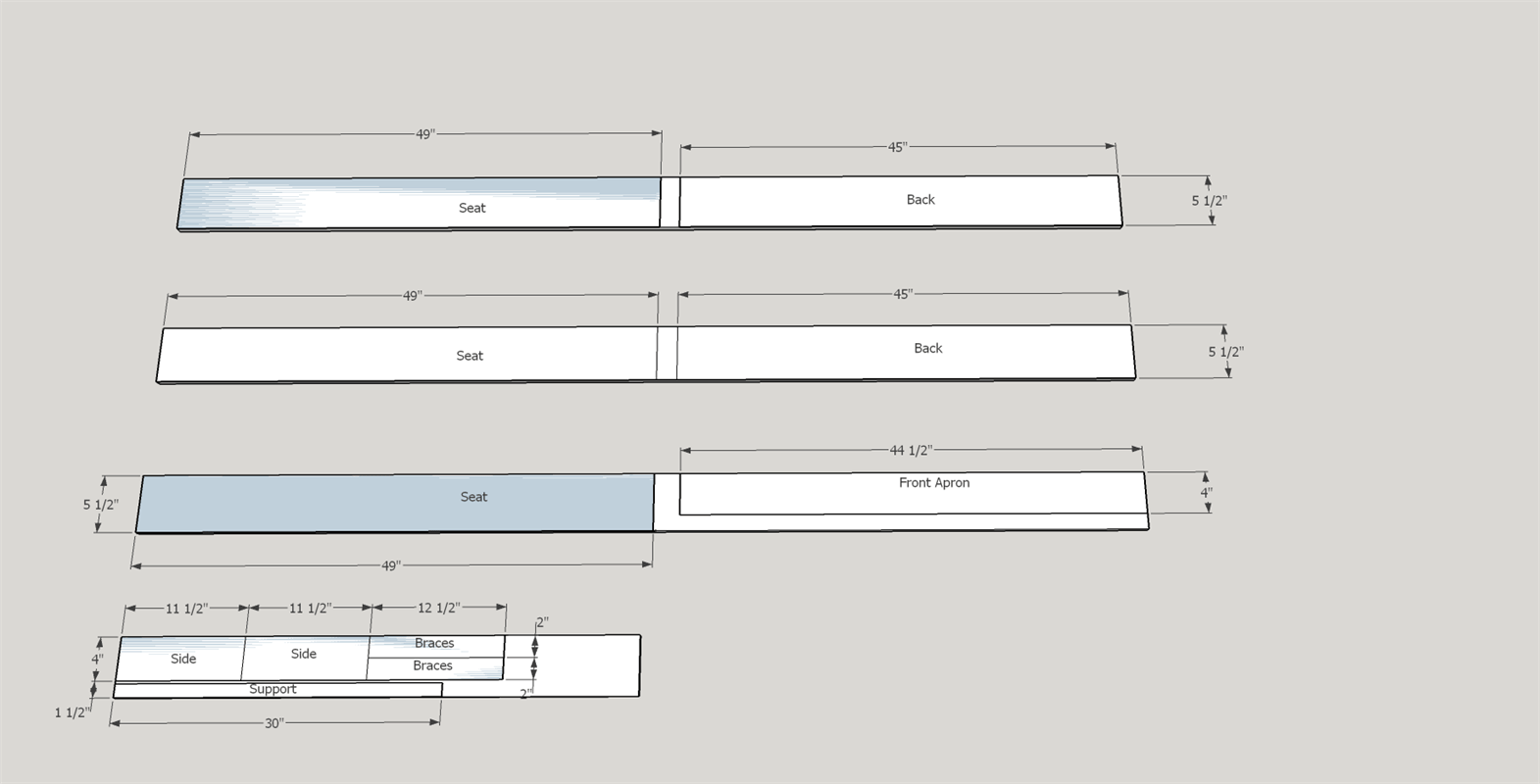

Cut 3/4" oak bench pieces

Using the dimensions in the following diagram cut the pieces required for assembly. Please note that the seat will require glueing up three pieces and the back will require two. When edge glued these individual pieces will make wide boards that are larger than the finished seat and back. That is OK as we will eventually cut them to size.

-

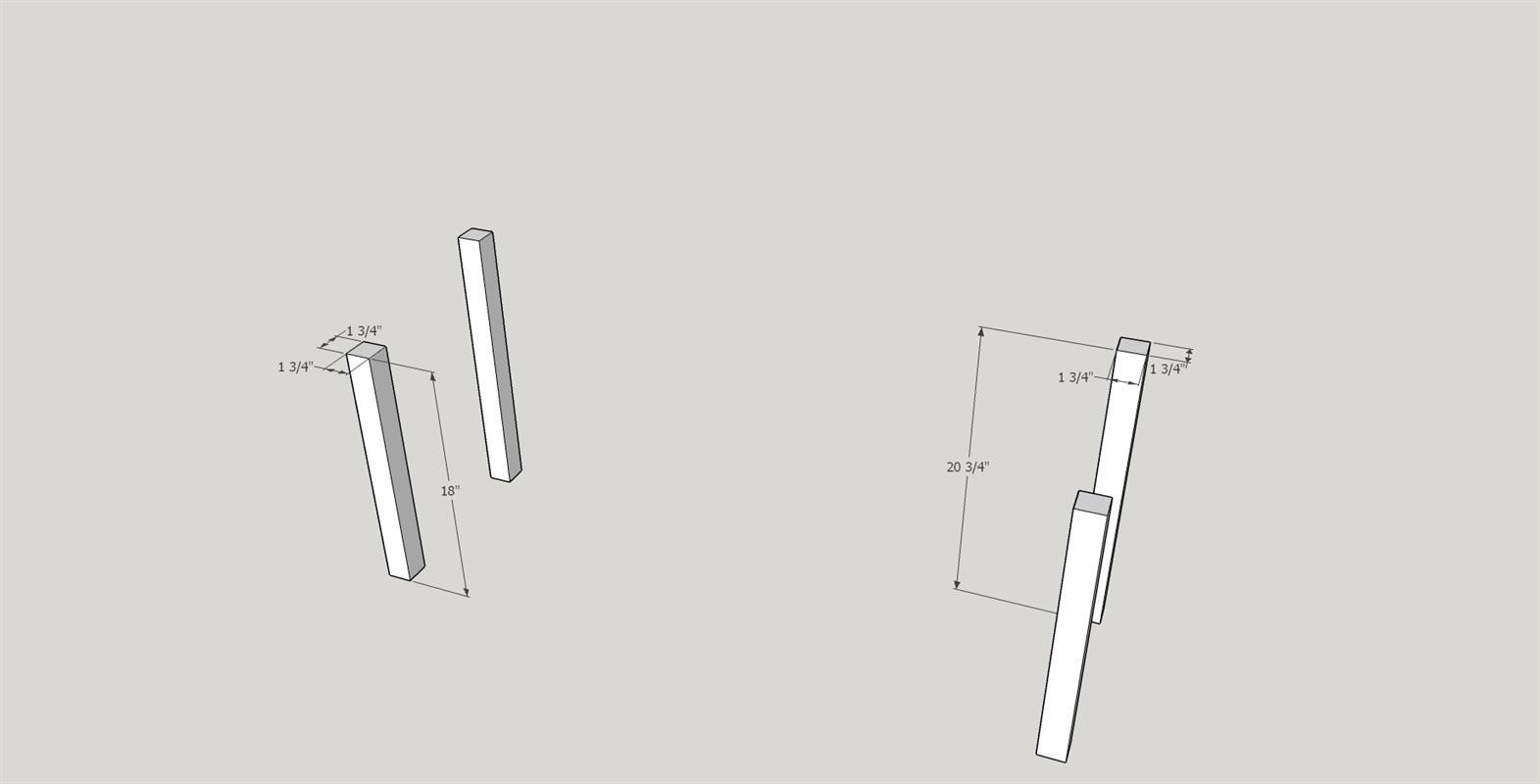

Cut the legs

Cut the rear and front legs to the dimensions shown in the following diagram. If you plan to use the bench outside, I recommend using 8/4 oak so that the legs are one solid piece. If you are going to use the bench inside, legs cut from laminated boards will work. Use 100 grit then 150 grit sandpaper to smooth the legs.

-

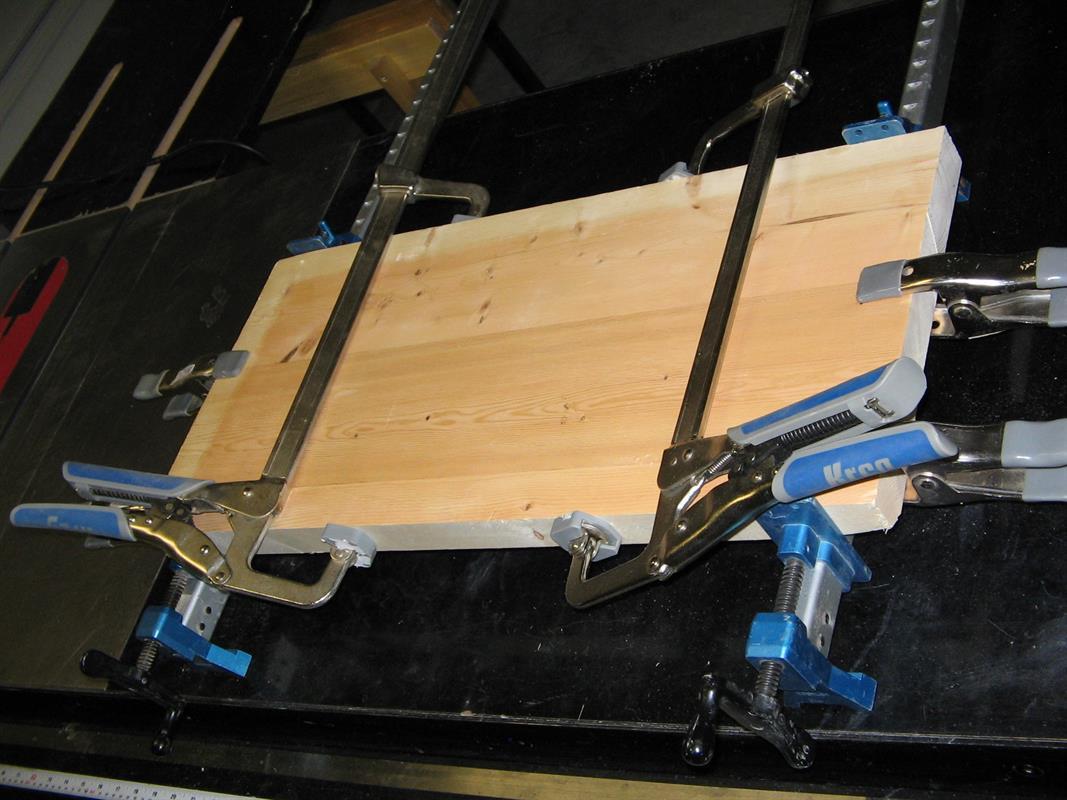

Edge gluing the seat and back

For the seat we will edge glue the three 3/4" X 49" X 5 1/2" boards and for the back we will edge glue the two 3/4" X 45" X 5 1/2" boards. If you are uncomfortable doing this I have attached one site with good information on the process. Please feel free to look at other sites. I normally use my Jet jointer to square and flatten the edges. Lay out the boards to provide the best looking grain. Use multiple clamps to bring the boards together. Make sure that the edges fit together well. Release the clamps and spread Titebond III waterproof glue along all of the edges to be joined. Avoid using excess glue. Realign the boards and clamp snugly. A picture of a typical clamp up follows.

-

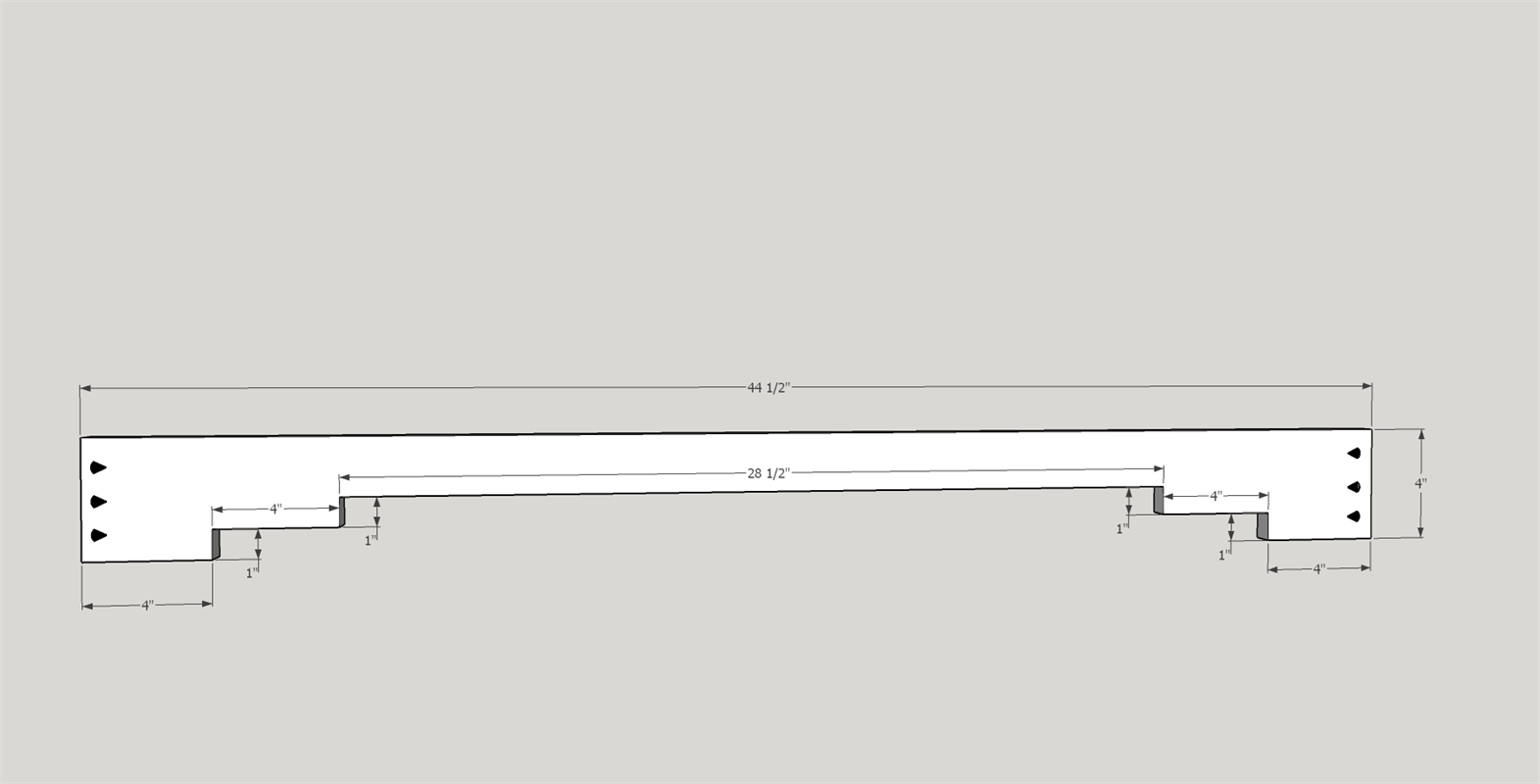

Completing the front apron

Using a Kreg pocket jig (set to 3/4" for all holes in this design) put three holes in each end of the apron. It is a good idea to mark where the holes will be to prevent mistakes. Using the dimensions on the following diagram draw the step design on the apron. Using either a band saw or jig saw cut out the design. Sand with 100 grit then 150 grit sandpaper.

-

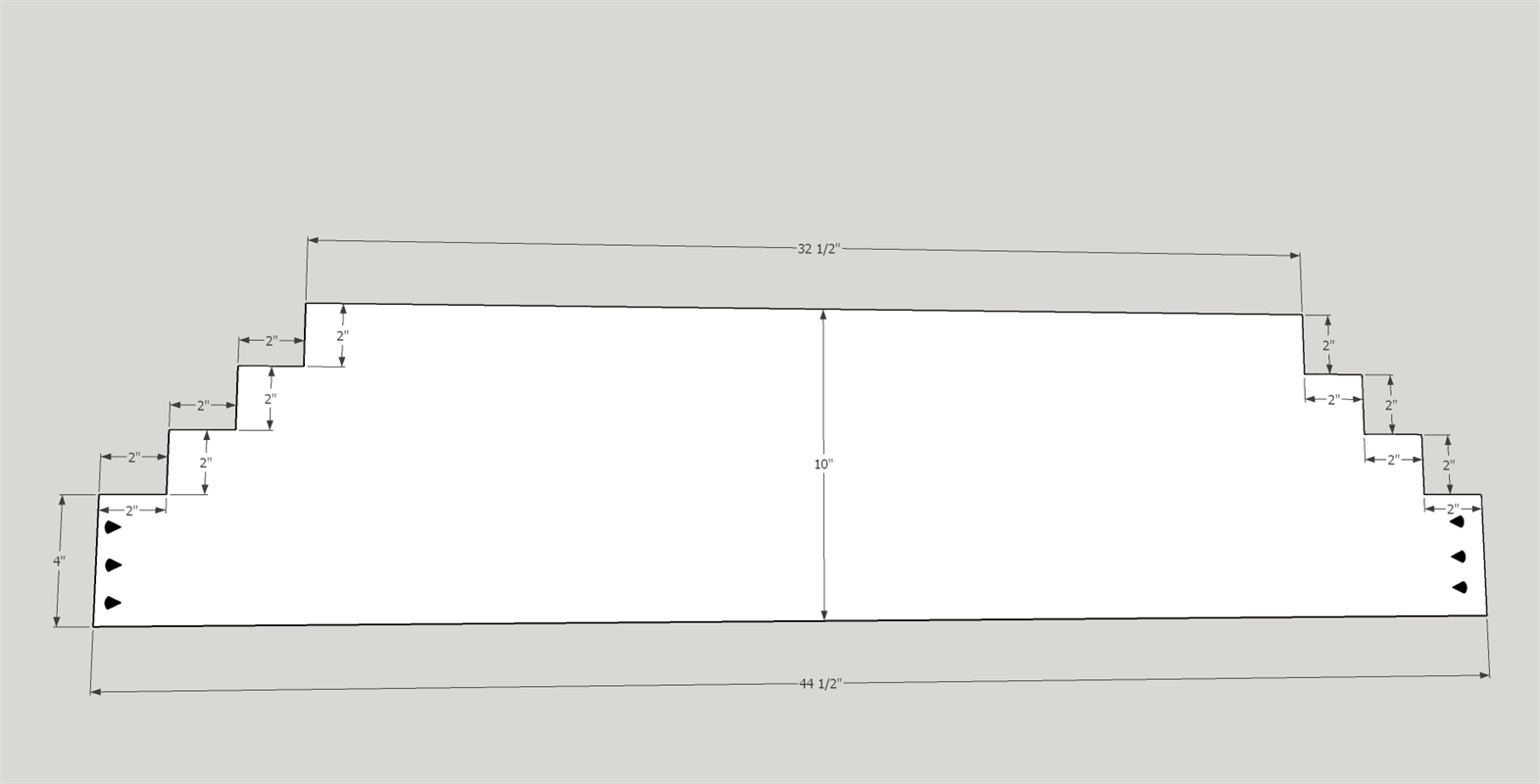

Completing the sides

Using a Kreg pocket jig put three holes in ends of the two sides. Again it is a good idea to mark where the holes will be to prevent mistakes. Using the dimensions on the following diagram draw the step design on the sides. Using either a band saw or jig saw cut out the design. Sand with 100 grit then 150 grit sandpaper.

-

Completing the back

Once the glue up of the back has dried cut to final dimensions of 44 1/2" X 10". Using a Kreg pocket jig put three holes in bottom four inches of both ends of the back. Again it is a good idea to mark where the holes will be to prevent mistakes. Using the dimensions from the following diagram draw the step design on the back. Using either a band saw or jig saw cut out the design. Sand with 100 grit then 150 grit sandpaper.

-

Zia Sun Sign - OPTIONAL

If you want to add the Zia Sun Sign, or any other design to the back, now is a good time to do it. I found a drawing of the Zia Sun Sign on the internet and printed a copy. I used that copy to trace the design to the center of the back. I used chisels and an Xacto type knife to outline the design. Then I used a 1/4" chisel and a wood gouge to carve out the design. Make sure that you put the design on the opposite side of the pocket holes.

-

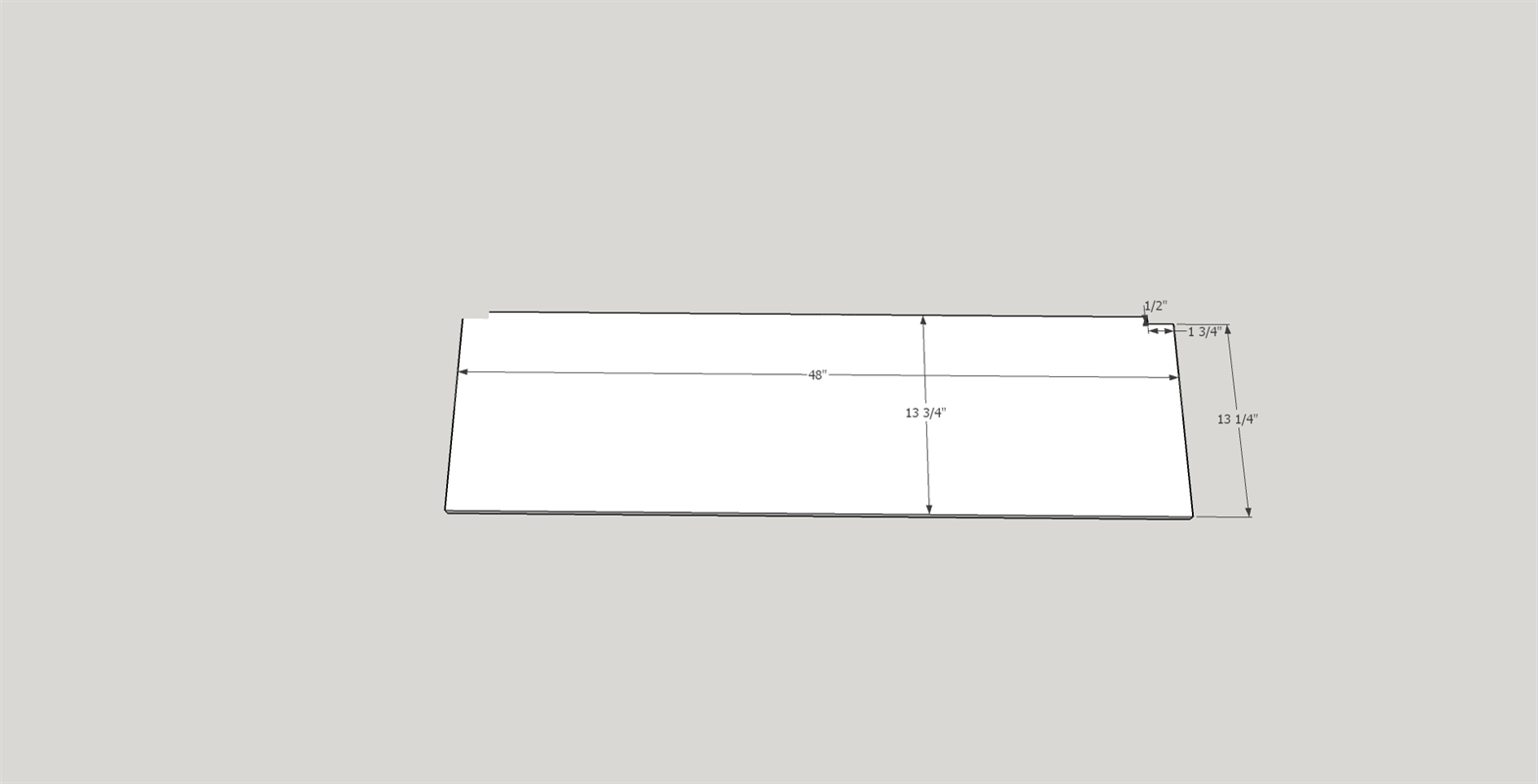

Completing the seat

Once the glue up of the seat has dried, cut to final dimensions of 48" X 13 3/4". Using the dimensions from the following diagram mark the two corner reliefs in the seat. Using either a band saw or jig saw cut out the reliefs. Sand with 100 grit then 150 grit sandpaper.

-

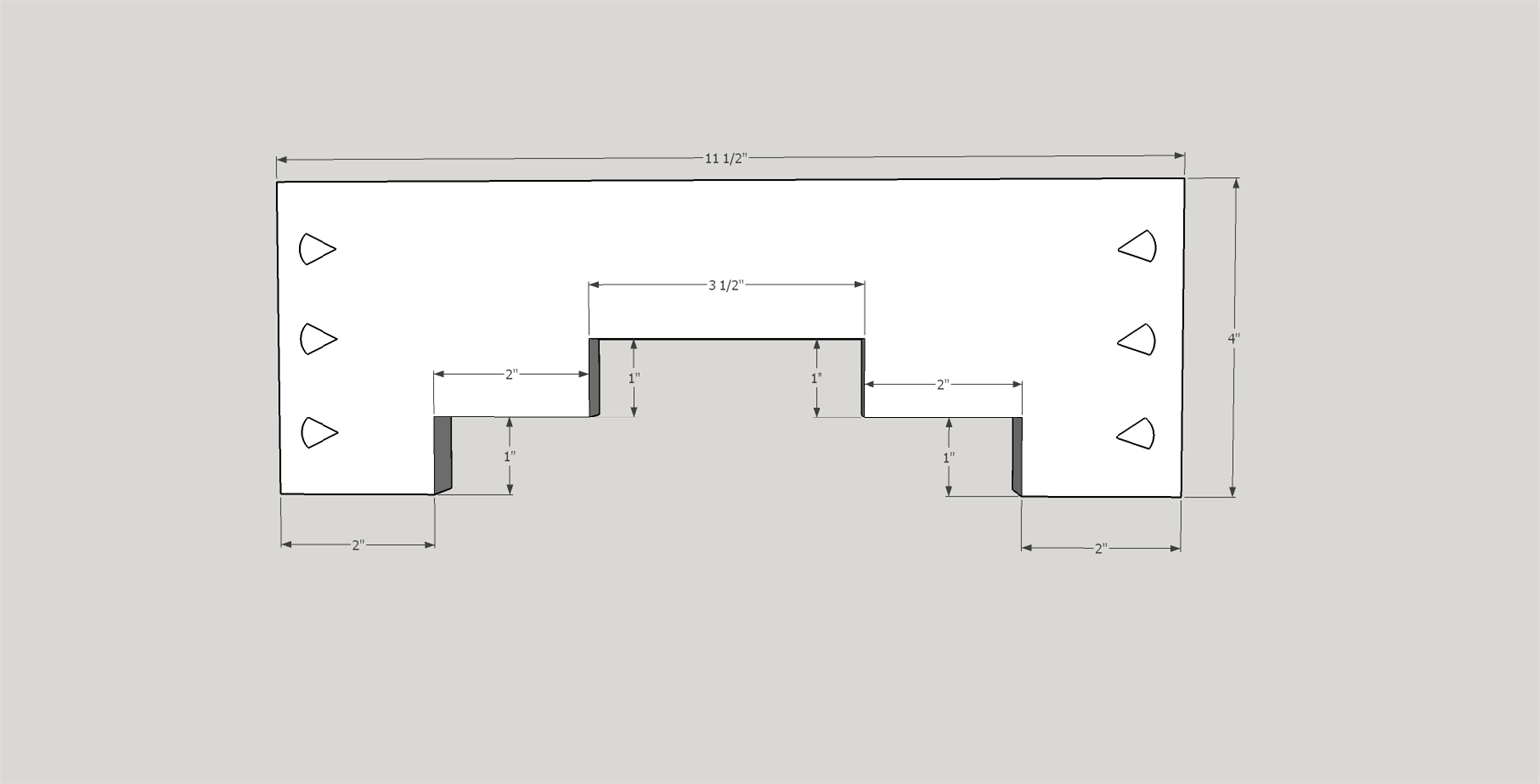

Completing the seat braces

Using a Kreg pocket jig put two holes in both ends of the seat braces. Again it is a good idea to mark where the holes will be to prevent mistakes. At approximately 2" in from the ends and 1" from the sides drill four 1/4" holes through the braces. These will be used to attach the seat to the frame. Sand with 100 grit then 150 grit sandpaper.

-

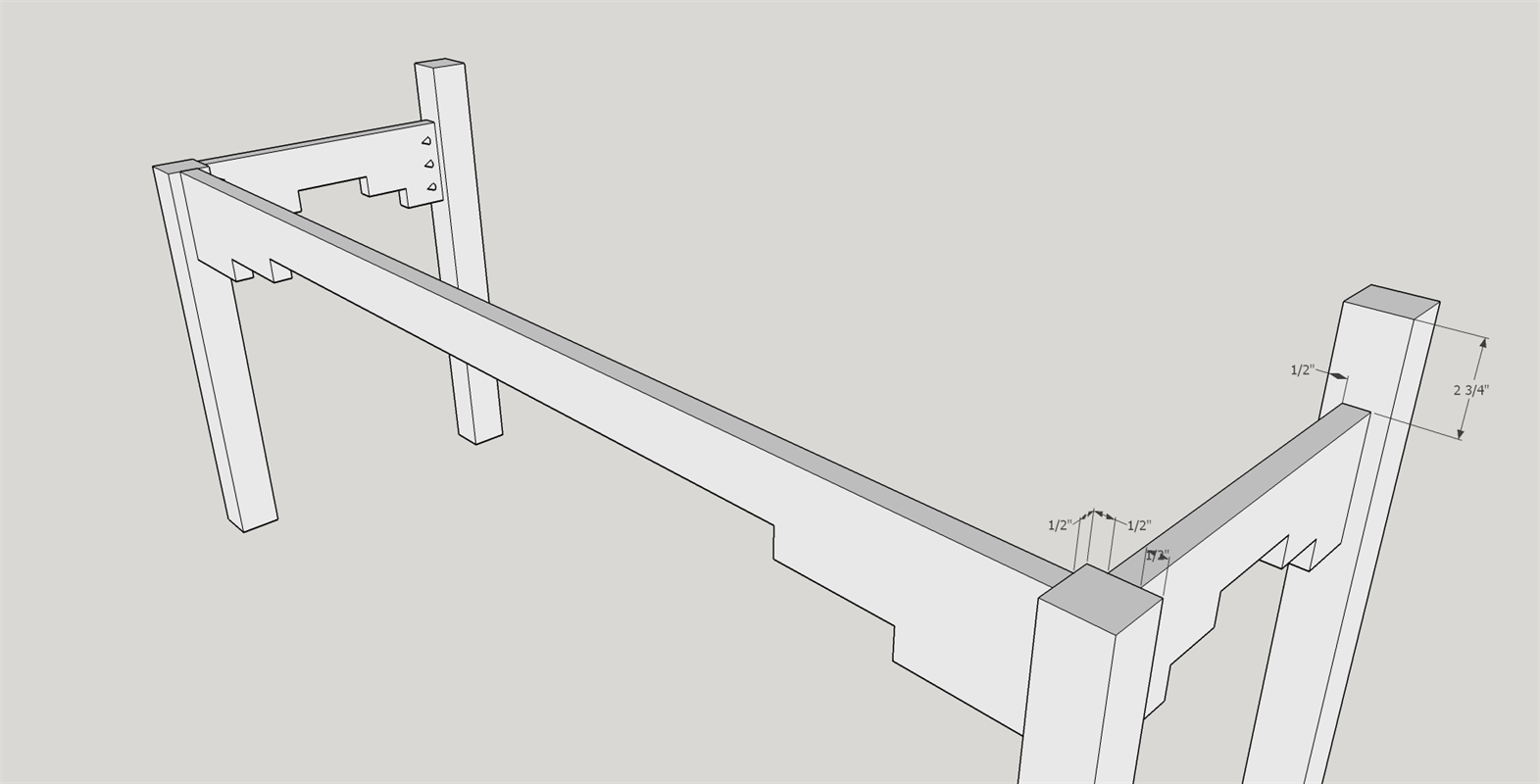

Beginning frame assembly

Begin assembling the frame by attaching the front apron to the two shorter legs. The apron should be flush with tops of the legs and 1/2" from the front of the legs. Attach using Titebond III glue and Kreg 1 1/4" fine pocket screws. Now attach the sides, with glue and screws, they are also flush with the top of the front leg and 1/2" in from the side of the leg. Please make sure that the pocket holes all face inside the frame. Next attach the back legs. The sides should attach 1/2" in from the leg sides and 2 3/4" from the top. Again use screws and glue. Use a damp cloth to wipe off any excess glue.

-

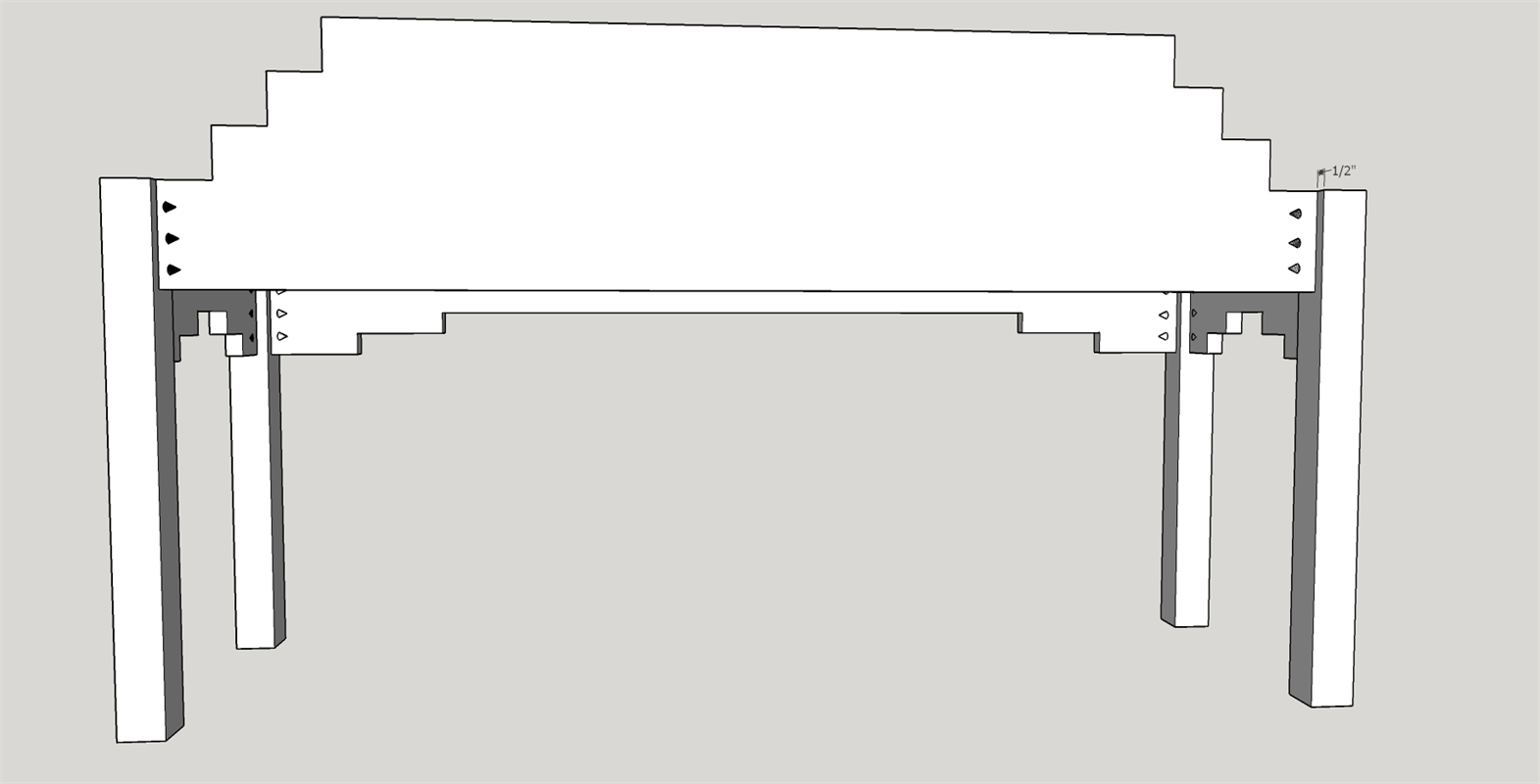

Add the back to the frame

Attach the back to the frame. It should be 1/2" in from the back of the back legs and the first step should be flush with the top of the back leg. See diagram that follows. Make the attachment with Titebond III and Kreg 1 1/4" fine pocket screws. Use a damp rag to remove any excess glue.

-

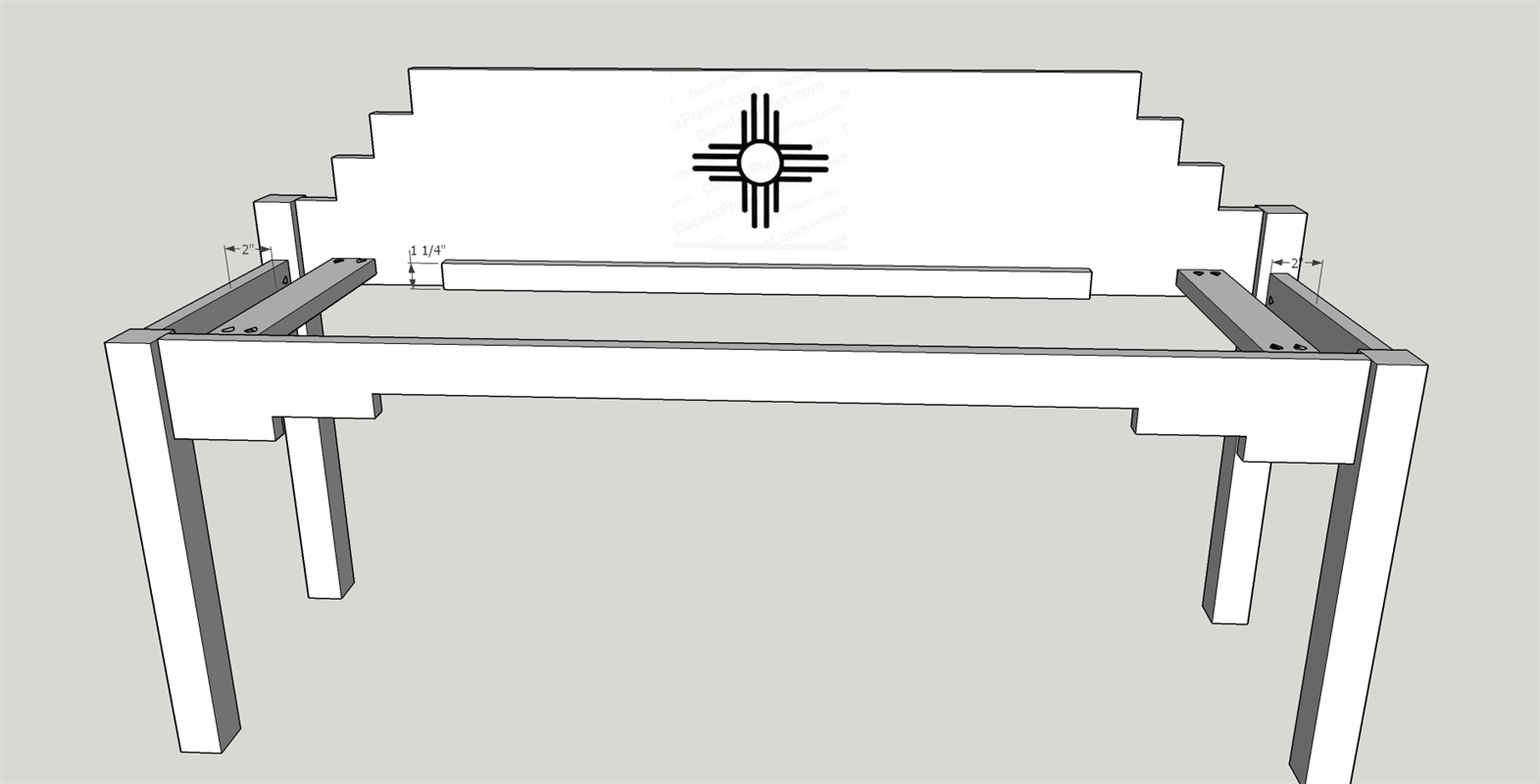

Complete frame assembly

To complete the frame we will add the two seat braces and the the seat support. Using Titebond III wood glue and Kreg 1 1/4" fine pocket screws to attach the braces. They should be parallel with the sides at a distance of 2". The seat support is centered between the sides and attached flush with the bottom of the seat back. Use wood glue and 1 1/4" brad nails to attach.

-

Attach seat

Set the seat in place. It should set against the back and between the two back legs. The seat is held in place by four Kreg 1 1/4" fine pocket screws that have flat washers added. (see picture) From the underside of the bench insert the screws through the four 1/4" holes drilled into the seat braces. The screws should be drawn snug but not over tight. This should hold the seat in place but allow for any expansion or contraction of the seat board.

-

Finish

Now that the build is complete use 220 sandpaper to do a once over on all surfaces in preparation for the finish. Clean well to remove all dust. (I use compressed air and clean dry rags). As this was going onto the front porch of our adobe style house, I chose to use weathered oak Minwax Stain. For the Zia Sun Sign I stained the center of the design with Minwax red oak stain and the sun rays were colored black with a Sharpie permanent marker. After the stains had dried I finished the bench with Varathane Spar Urethane Satin clear oil based finish. I gave the bench four coats following manufacturers instructions.