If you need to cut trim, remove grout or similar tasks, this is one of the most versatile power tools you can own. There are so many uses for an oscillating multi-tool and it replaces a handful of single-purpose tools, fits into tight spaces, and handles detailed work that other tools can’t.

What Is an Oscillating Multi-Tool?

An oscillating multi-tool (often called a multi-tool or oscillating tool) is a compact, handheld power tool that uses rapid side-to-side motion to cut, scrape, sand, and more. Unlike a spinning blade, the tool vibrates in a small arc — usually just a few degrees — giving you incredible control in tight spaces and on delicate materials.

How This Versatile Tool Transforms Project Efficiency

Think of an oscillating tool as a project problem-solver. One tool can handle dozens of tasks:

- Plunge cuts without pre-drilling.

- Flush-cutting wood, nails, or PVC pipes.

- Scraping old caulk, paint, or flooring.

- Sanding corners and awkward angles.

- Removing grout without damaging tiles.

It’s especially handy where a circular saw, jigsaw, or reciprocating saw can’t fit.

Key Applications and Benefits Overview:

Precision

Great for fine control and detail work.

Versatility

Works on wood, metal, drywall, tile, plastic, and more.

Compactness

Fits into tight spaces larger tools can’t reach.

Accessory variety

Swap blades, scrapers, and sanding pads as needed.

Essential Parts and Attachments

Before you start, get to know your tool and its accessories.

Core Components

Tool head

Where blades and attachments lock in — most are tool-free for quick changes.

Motor housing

Powers the oscillation; located in the main body.

Variable speed control

Adjusts oscillation speed for different materials.

Corded or cordless power

Corded tools deliver constant power, while cordless tools add mobility and convenience.

Must-Have Attachments

You don’t need a huge collection to get started. Stick to the essentials:

Bi-metal plunge-cut blade

Cuts wood, nails, drywall, and PVC — the ultimate general-purpose blade.

Wood-cutting blade

Faster, cleaner cuts in wood.

Scraper blade

Removes old paint, adhesive, or caulk.

Grout-removal blade

Carbide or diamond-tipped for precision grout work.

Sanding pad + hook-and-loop sandpaper

Detail sanding in corners or small surfaces.

Getting Started: Setup and Safety

Before using an oscillating tool, set it up correctly and follow safety best practices.

Choose the Right Attachment

Pick the right blade or accessory based on the job:

Wood-only cuts

Use a fine-tooth wood blade.

Metal or mixed cuts

Use a bi-metal blade.

Tile grout removal

Use carbide-grit or diamond blades.

Scraping paint or adhesives

Go with a flexible scraper blade.

Detail sanding

Use a triangular sanding pad with the right grit paper.

Safety Gear You’ll Want

Even though oscillating tools feel approachable, they’re still power tools and you need to take the proper precautions with the right gear:

- Eye protection

- Hearing protection

- Dust mask

- Gloves

Set the Right Speed

If your tool offers variable speeds, match the speed to the material:

- Low speed — sanding or working with delicate materials

- Medium speed — standard wood cutting and detail work

- High speed — metal, tile, or hardened adhesives

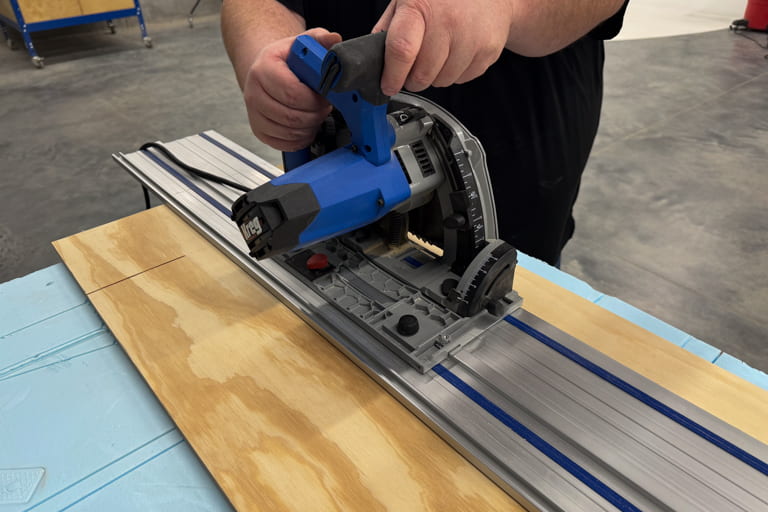

How to Use an Oscillating Multi-Tool

Using a multi-tool is straightforward once you’ve got the basics down.

Step 1: Attach the Blade

Unplug the tool or remove the battery.

Align the blade opening with the mounting post.

Lock it securely using the lever or wrench.

Double-check the blade direction before powering up.

Step 2: Test First

Practice on scrap material to:

Get used to the tool’s vibration.

Dial in the right speed.

Find the best pressure and cutting angle.

Step 3: Start Cutting, Sanding, or Scraping

Plunge cuts

Angle the blade slightly, then rock gently into the material.

Flush cuts

Keep the blade flat against the surface for clean results.

Scraping

Use a shallow angle and slow movements.

Sanding

Keep the pad flat and moving — don’t linger in one spot.

Beginner Tips for Better Results

Keep the following in mind to make it easier to cut cleanly, extend blade life, and stay in control:

Use both hands

One for power, one near the head for control.

Let the tool work

Don’t force the blade; slow, steady pressure gives smoother results.

Mark your depth

Use painter’s tape as a visual guide on the blade.

Control vibration

Relax your grip and take breaks during longer jobs.

Work with the right angle

Keep blades flat for flush cuts; tilt slightly for plunge cuts.

Advanced Techniques to Try

Once you’re comfortable, you can tackle more challenging tasks:

Plunge Cuts with Precision

One of the tool’s standout features is making cuts without pre-drilling:

- Mark your cut clearly with painter’s tape.

- Start at a slight angle, then straighten as you go deeper.

- Use a guide board clamped alongside the cut line for perfect results.

Common Oscillating Tool Projects and Uses

Oscillating tools excel in dozens of situations. Here are a few:

Trim and Woodwork

- Undercut door jambs for flooring.

- Flush-cut baseboards or shims.

- Trim spacers during cabinet installs.

Drywall and Renovation

- Cut drywall for electrical boxes.

- Trim edges cleanly during patches.

- Scrape off adhesive or wallpaper.

Tile and Bathroom Work

- Remove grout without chipping tiles.

- Trim cement board for tight fits.

- Scrape caulk or sealant cleanly.

Flooring and Demolition

- Cut nails or fasteners during tear-outs.

- Remove vinyl, carpet glue, or thinset.

- Undercut trim to fit new flooring.

Metal and Finishing Tasks

- Cut screws, nails, or pipes.

- Sand away rust spots.

- Remove old paint drips or overspray.

Complete Accessory Guide: The Right Tool for Every Job

The real power of a multi-tool comes from matching the attachment to the task:

Round vs. straight blades

Use round blades for plunge cuts and curves; straight blades excel at long, controlled cuts.

Scraper vs. grout blades

Scrapers lift paint and adhesives; grout blades grind away grout without damaging tiles.

Specialty blades

Choose metal-only, wood-only, or combo blades for projects that require cutting multiple materials.

Sanding pads

Triangular pads for corners and detail sanding

Rectangular pads for larger flat areas

Start coarse, finish fine: 80 grit → 150 grit → 220 grit for smooth results

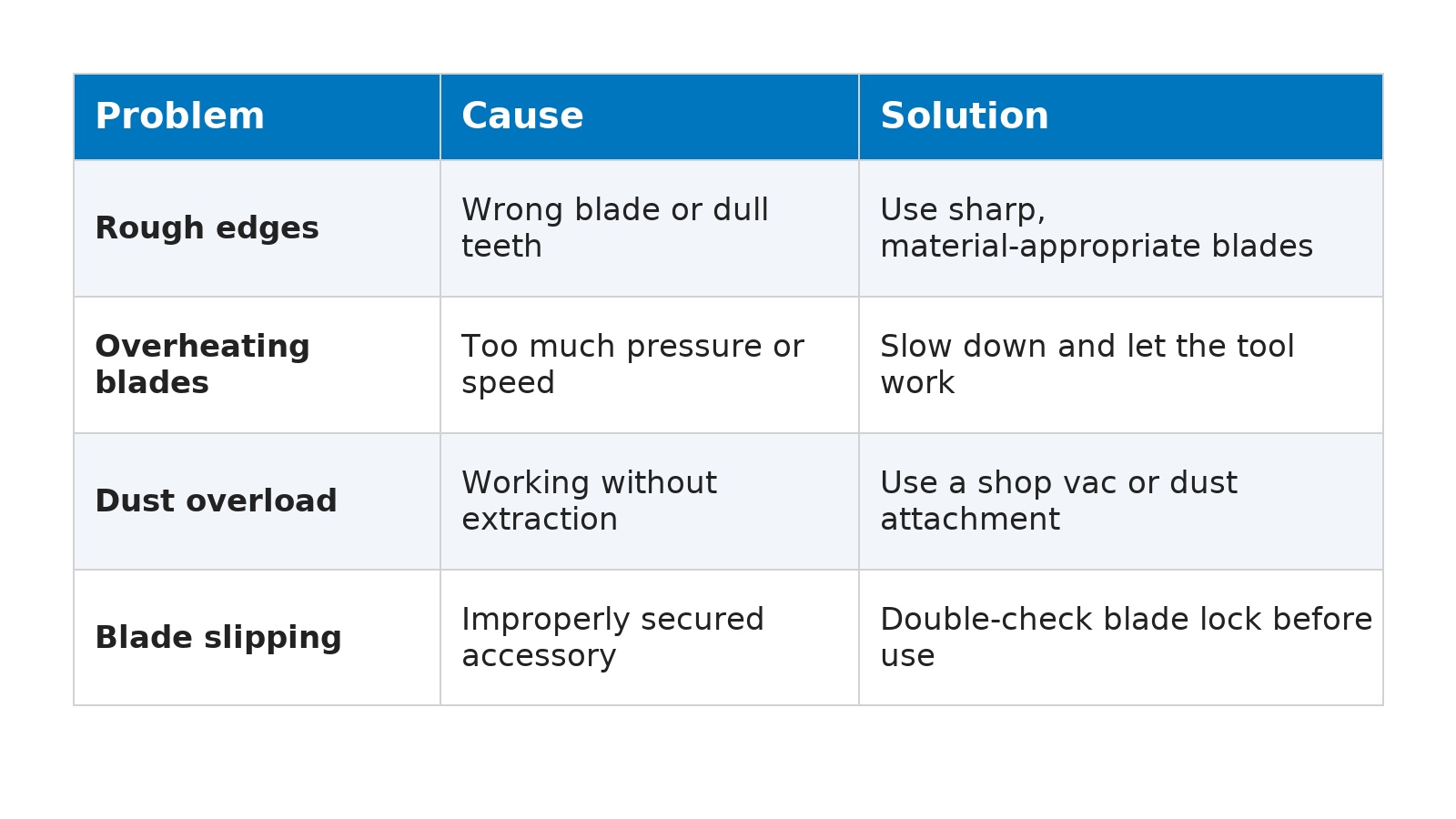

Troubleshooting Common Problems